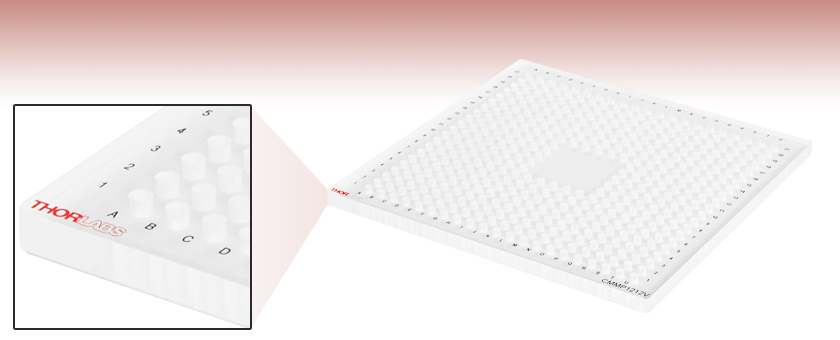

Optically Clear Acrylic Breadboard

- Optically Clear Acrylic for High Transmission in the Visible and NIR

- 1/4"-20 Tapped Through Holes for Mounting

- Central Unobstructed Viewing Window

- Ideal for Vision Systems and Metrology

CMMP1212V

Acrylic Breadboard

Alphanumeric Labels

Allow for Mounting

Hole Identification

Please Wait

Click to Enlarge

The front plate of a Polaris® mirror mount is secured on the

CMMP1212V within a vision system to verify its dimensions. Cap screws were used to secure and create stops for the parts being inspected.

See the Application Idea tab for details.

Features

- 12" x 12" (304.8 mm x 304.8 mm) Optically Clear Acrylic Breadboard

- On-Axis Alphanumeric Labels Indicate Mounting Hole Locations

- 1/4"-20 Tapped Holes on 0.50" (12.7 mm) Centers

- Central Window for Unobstructed Viewing of Parts

- Heat Treated and Polished to Maintain Clarity and Resist Cracking

- Ideal for Vision Systems and Metrology

Thorlabs' CMMP1212V Breadboard is crafted from polished, optically clear acrylic and is ideal for applications that require parts to be backlit and fixed in place at specific reference positions, such as vision metrology. Each breadboard contains a pattern of 1/4"-20 tapped through holes, spaced 0.5" (12.7 mm) apart, that is offset by 1.0" (25.4 mm) from the edges of the board. This allows for an increased number of mounting options for components when compared to breadboards that have a standard 1" or 25.0 mm hole pattern or a double-density 0.5" or 12.5 mm hole pattern. Within the 1.0" wide region on each side are on-axis alphanumeric labels for identifying specific rows, columns, or mounting holes.

A 2.72" x 2.72" (69.2 mm x 69.2 mm) center-located window is included for components or smaller parts that need to be viewed without obstructions such as mounting holes. Constructed from acrylic, the breadboard has high transmission in the visible and near-IR regions of the spectrum as shown in the graph within the Specifications table to the right.

Each acrylic breadboard is heat treated and polished to provide the highest quality breadboard possible. Heat treating the acrylic and letting it cool in a controlled environment removes the internal stresses that develop during the casting process, creating a more stable, crack-resistant breadboard that has a longer lifetime. This in addition to a high-quality polish ensures that the board will remain optically clear and resist yellowing for a longer period of time.

We also offer a broad selection of solid aluminum breadboards as well as steel and aluminum honeycomb breadboards. For a quick comparison of our different breadboard options, please see the BB Selection Guide tab.

Click to Enlarge

A CMMP1212V Being Used within an Optek Vision Metrology System

Vision/Video Metrology

The CMMP1212V Tapped Breadboard is the ideal solution for securely holding parts for inspection with vision metrology systems. Vision, or video, systems provide rapid, non-contact 3-axis coordinate measurement of a part under inspection. Using a tapped breadboard with one of these systems allows for defined reference points to be set up before placement into the system, which shortens the amount of time between runs, allows for multiple parts to be checked at once, and allows for parts to be secured in place via fixtures.

Click to Enlarge

The front plate of a Polaris® mirror mount is secured on the CMMP1212V within a vision system to verify its dimensions. Cap screws were used to secure and create stops for the parts being inspected.

Since vision systems implement both front and backlighting methods for illuminating parts, it is important that the mounting surface is able to transmit a large amount of light. Constructed from optically clear acrylic and finished with a clear polish, the CMMP1212V provides high transmission in the visible and near-IR regions of the spectrum. This means that edges and through holes of an item under inspection can be clearly visualized and measured when backlighting is used.

At 0.5" (12.7 mm) thick, parts mounted on or above the surface of the breadboard will not interfere with the imaging camera. The 12" x 12" (304.8 mm x 304.8 mm) size is compact and will fit within most vision systems, while providing enough space to mount multiple components.

An array of 1/4"-20 tapped mounting holes allows for the addition of fixtures to secure multiple items in place, while the alphanumeric labels around the edges help to create reference points when inspecting multiple items. An included 2.72" x 2.72" (69.2 mm x 69.2 mm) window is ideal for smaller parts that cannot be visualized when mounted over obstructions such as mounting holes.

An example of the CMMP1212V being used within a vision system is shown above. In this setup, multiple parts are mounted on the breadboard for inspection. The part being inspected in the photo is the front plate of a Polaris mirror mount. The front plate was mounted over the central viewing window so that the smaller through holes could be examined and measured before production.

| Posted Comments: | |

muellenbroich

(posted 2017-02-14 09:46:42.85) Hi there,

is it possible to make custom versions of this product?

thanks! tfrisch

(posted 2017-02-14 03:40:39.0) Hello, thank you for contacting Thorlabs. I will reach out to you directly about the details of the custom you would need. |

| Breadboards |  Nexus, Optimized Damping |

Intrinsically Damped |

Aluminum Honeycomb |

Stainless Steel |

Solid Aluminum |

Optically Clear Acrylic |

|---|---|---|---|---|---|---|

| Construction | ||||||

| Breadboard Thickness | 60 mm (2.4") 110 mm (4.3") |

58 mm (2.28") | 25 mm (0.98") 55 mm (2.2") |

12.7 mm (0.5") | 7.0 mm (0.28") 9.5 mm (0.375") 12.7 mm (0.5") 19.05 mm (0.75") |

12.7 mm (0.5") |

| Working Surface | 430 Grade Stainless Steel or 304L Grade Nonmagnetic Steel Top Plate | 430 Grade Stainless Steel Top Plate | Aluminum | 416 Grade Stainless Steel | Solid Aluminum Anodized or Unanodized |

Acrylic |

| Top Skin | 5 mm (0.20") | 5 mm (0.20") | 6 mm (0.24") | N/A | N/A | N/A |

| Bottom Skin | 5 mm (0.20") | 3 mm (0.12") | 3 mm (0.12") | N/A | N/A | N/A |

| Core Design | High-Density Plated Steel Honeycomb, 0.26 mm Thick | High-Density Plated Aluminum Honeycomb | N/A | N/A | N/A | |

| Side Panels | Rigid Steel Box Section | Unplasticized Polyvinyl Chloride (uPVC) | Black Laminated Aluminum Sides |

N/A | N/A | N/A |

| Ferromagnetism | Magnetic or Non-Magnetic Options | Magnetic | Non-Magnetic | Magnetic | Non-Magnetic | |

| Sealed Holes | Sealed (25 mm Depth) or Non-Sealed Options | Non-Sealed | N/A | N/A | N/A | |

| Thread Options | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6), 4-40 (M3), or 8-32 (M3) and 1/4"-20 (M6) Tapped Holes |

1/4-20" Tapped Holes | |

| Spacing | 1" (25 mm) Centers | 1" (25 mm) Centers | 1" (25 mm) Centers | 1" (25 mm) Centers or 0.5" (12.7 mm) Centers |

0.5" (12.7 mm) Centers | |

| Distance from Edge to First Holes |

0.5" (12.5 mm) on all Sides | 0.5" (12.5 mm) or 1.0" (25 mm) on all Sides |

0.5" (12.5 mm) on all Sides | 0.5" (12.5 mm) on all Sides | 1.0" (25.4 mm) on all Sides | |

| Performancea | ||||||

| Damping |  |

|

|

N/A | N/A | N/A |

| Stiffness |  60 mm (2.4") Thick |

58 mm (2.28") Thick |

25 mm (0.98") Thick |

12.7 mm (0.5") Thick 12.7 mm (0.5") Thick |

7.0 mm (0.28") Thick |

12.7 mm (0.5") Thick |

110 mm (4.3") Thick |

55 mm (2.2") Thick |

19.05 mm (0.75") Thick 19.05 mm (0.75") Thick |

||||

Optical Breadboard Selection Guides

The selection guides below list every size offered for our honeycomb, solid aluminum, and acrylic breadboards. Simply locate the specific width and length needed and then select the type of breadboard. Expand each table by clicking the More [+] button within the header.

Thorlabs also offers several unique breadboard solutions. For applications requiring temperature control, we offer anodized aluminum water cooled breadboards in several sizes, in addition to a temperature-controlled mini-series breadboard for small-scale operations. Our anodized aluminum large-area translation stages and rotating breadboards offer hand-operated positioning control, while our manual and motorized translating mounting platforms are ideal for use in microscopy applications.

| Imperial Optical Breadboard Size Options | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Honeycomb | Stainless Steel | Solid Aluminuma | Acrylic, Transparent | ||||||

| Nexus (60 mm Thick)b |

Nexus (110 mm Thick)b |

Intrinsically Damped (58 mm Thick) |

Aluminum (25 mm Thick) |

Aluminum (55 mm Thick) |

Standard | Double Density | High Density | ||||

| Metric Optical Breadboard Size Options | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Honeycomb | Stainless Steel | Solid Aluminuma | ||||||

| Nexus (60 mm Thick)b |

Nexus (110 mm Thick)b |

Intrinsically Damped (58 mm Thick) |

Aluminum (25 mm Thick) |

Aluminum (55 mm Thick) |

Standard | Double Density | High Density | |||

| 50 mm | 75 mm | - | - | - | - | - | - | - | - | MSB5075/M |

| 75 mm | 100 mm | - | - | - | - | - | - | - | - | MSB7510/M |

| 75 mm | 150 mm | - | - | - | - | - | - | - | - | MSB7515/M |

| 100 mm | 100 mm | - | - | - | - | - | MB10S/M | - | - | - |

| 100 mm | 150 mm | - | - | - | - | - | MB1015S/M | MB1015/M MB1015U/M |

M45B1015/Mc | MSB1015/M |

| 100 mm | 300 mm | - | - | - | - | - | - | MB1030/M | - | - |

| 100 mm | 600 mm | - | - | - | - | - | - | - | MB1060/M | - |

| 100 mm | 900 mm | - | - | - | - | - | - | - | MB1090/M | - |

| Ø149 mm | - | - | - | - | - | - | - | MBR150U/M | - | |

| Ø150 mm | - | - | - | - | - | - | - | MBR150/M | - | |

| 150 mm | 150 mm | - | - | - | - | - | MB15S/M | MB1515/M MB1515U/M |

M45B1515/Mc | MSB15/M |

| 150 mm | 300 mm | - | - | - | - | - | - | MB1530F/M | MB1530/M M45B1530/Mc |

- |

| 150 mm | 450 mm | - | - | - | - | - | - | MB1545/M | - | - |

| 150 mm | 600 mm | - | - | - | - | - | - | MB1560/M | - | - |

| 150 mm | 900 mm | - | - | - | - | - | - | MB1590/M | - | - |

| 150 mm | 1200 mm | - | - | - | - | - | - | MB15120/M | - | - |

| 180 mm | 230 mm | - | - | - | - | - | - | - | - | MSB1823/M MSBU1823/M |

| 200 mm | 200 mm | - | - | - | - | - | - | MB2020/M MB2020U/M |

- | - |

| 200 mm | 250 mm | - | - | - | - | - | - | MB2025/M | - | - |

| 200 mm | 600 mm | - | - | - | - | - | - | - | MB2060/M | - |

| 200 mm | 900 mm | - | - | - | - | - | - | - | MB2090/M | - |

| 250 mm | 300 mm | - | - | - | - | - | - | MB2530/M MB2530U/M |

- | - |

| Ø300 mm | - | - | - | - | - | - | - | MBR300/M MBR300U/M |

- | |

| 300 mm | 300 mm | B3030Ad B3030Ld |

- | - | PBG3030Ae | - | - | MB3030/M MB3030U/M |

MB3030D/M | MS12B/M MSB30/M |

| 300 mm | 450 mm | B3045Ad B3045Ld |

- | B3045AX | PBG3045Ae | - | - | MB3045/M MB3045A/Mf MB3045U/M |

- | MSB3045/M |

| 300 mm | 600 mm | B3060Ad B3060L |

- | B3060AXd | PBG3060A | PBG52502d | - | MB3060/M MB3060U/M |

- | - |

| 300 mm | 900 mm | B3090Ad B3090Ld |

- | - | PBG3090Ae | PBG52503d | - | MB3090/M | - | - |

| 300 mm | 1200 mm | - | - | - | - | - | - | MB30120/M | - | - |

| 350 mm | 1150 mm | - | - | - | - | - | - | MB35115/M | - | - |

| 350 mm | 1425 mm | - | - | - | - | - | - | MB35142/M | - | - |

| 450 mm | 450 mm | B4545Ad B4545Ld |

- | - | PBG4545A | - | - | MB4545/M | - | - |

| 450 mm | 600 mm | B4560Ad B4560Ld |

- | B4560AXd | PBG4560Ae | PBG52522d | - | MB4560/M MB4560A/Mf MB4560U/M |

- | - |

| 450 mm | 750 mm | - | - | - | - | - | - | MB4575/M | - | - |

| 450 mm | 900 mm | - | - | - | - | - | - | MB4590/M | - | - |

| 600 mm | 600 mm | B6060Ad B6060L |

- | B6060AXd | PBG6060Ae | PBG52505d | - | MB6060/M | - | |

| 600 mm | 900 mm | B6090A B6090L B6090ANd B6090Z |

B6090Bd B6090Nd |

B6090AX | PBG6090Ae | PBG52506d | - | MB6090/M | - | - |

| 600 mm | 1200 mm | B60120A B60120L |

B60120Bd B60120Nd |

B60120AX | PBG60120Ae | - | - | MB60120/M | - | - |

| 600 mm | 1500 mm | - | B60150Bd B60150Nd |

- | - | PBG52508d | - | - | - | - |

| 750 mm | 750 mm | B7575A B7575L |

- | - | - | - | - | MB7575/M | - | - |

| 750 mm | 900 mm | B7590A B7590L B7590ANd B7590Z |

B7590Bd B7590Nd |

B7590AX | PBG7590Ae | PBG52510d | - | - | - | - |

| 750 mm | 1200 mm | B75120A B75120L B75120ANd B75120Z |

B75120B B75120Nd |

B75120AX | PBG75120Ae | PBG52511 | - | - | - | - |

| 750 mm | 1500 mm | - | B75150B B75150N |

B75150AX | - | - | - | - | - | - |

| 900 mm | 900 mm | B9090A B9090L |

B9090Bd B9090Nd |

- | - | - | - | - | - | - |

| 900 mm | 1200 mm | B90120A B90120L B90120AN B90120Z |

B90120B B90120N |

B90120AX | PBG90120Ae | PBG52513 | - | - | - | - |

| 900 mm | 1500 mm | - | B90150B B90150N |

B90150AX | - | PBG52514 | - | - | - | - |

| 900 mm | 1800 mm | - | B90180B B90180N |

B90180AX | - | - | - | - | - | - |

| 1200 mm | 1500 mm | - | B120150Bd B120150Nd |

- | - | - | - | - | - | - |

| 1200 mm | 1800 mm | - | B120180B B120180Nd |

- | - | - | - | - | - | - |

| 1250 mm | 1800 mm | - | - | - | - | PBG52521 | - | - | - | - |

Products Home

Products Home

Solid Acrylic Breadboard

Solid Acrylic Breadboard