Single-Axis Flexure Stages: 5 mm Travel

- Differential Adjusters

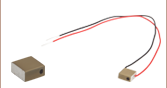

- Optional 20 μm Piezo Drive for Open- or Closed-Loop Operation

- Mounting Plate & Angle Bracket Accessories

NFL5DP20S

Shown with NFL5P1 Baseplate (Not Included)

NFL5P2

Angle Bracket

NFL5P1

Base Plate

Typical XZ

Configuration

Please Wait

| Key Specifications | |||

|---|---|---|---|

| Item # | NFL5D | NFL5DP20 | NFL5DP20S |

| Actuator(s) | Differential Micrometer |

Diff. Micrometer & Open-Loop Piezo |

Diff. Micrometer & Closed-Loop Piezo |

| Coarse Adjuster Travel | 5 mm (0.20") | ||

| Coarse Adjuster Resolution | 0.5 mm per Revolution | ||

| Fine Adjuster Travel | 300 µm | ||

| Fine Adjuster Resolution | 50 µm per Revolution | ||

| Load Capacity | Horizontal: 1 kg (2.2 lbs) Vertical: 0.5 kg (1.1 lbs) |

||

| Piezo Travel | N/A | 20 µm | 20 µm |

| Piezo Resolution (Theoretical) |

N/A | 0.6 nm | 0.6 nmb |

| Piezo Voltage | N/A | 0 - 75 V | 0 - 75 V |

| Single-Axis Flexure Stage Selection Guide |

|---|

| 1.5 mm Travel |

| 5 mm Travel |

Features

- Differential Adjuster Translation Range: 5 mm

- Optional 20 μm Piezo Drive

- NFL5DP20(/M): Open-Loop Operation

- NFL5DP20S(/M): Strain Gauge for Closed-Loop Operation

- Compact Size: 3.00" (75 mm) Square, 1.18" (30 mm) Thick

- XYZ-Configurable

- NFL5DP20(/M) Open-Loop Stage Available Bundled with KPZ101 Controller (See Bundle Tab for Details)

When stability is of the utmost importance, the NanoFlex™ 5 mm travel single-axis compound flexure stages provide ultra smooth translation for applications that are intolerant to the errors inherent in linear bearings. The compound linear symmetrical flexure design ensures true linear motion with zero cross talk over the full range of translation. This is achieved without the use of parts that require controlled contact to maintain their function; all the motion results from the flexing of various structural components within the translator. These features provide uncompromised performance, even when used in harsh environments.

These stages can be stacked in a 2-axis or 3-axis configuration using the optional base plate NFL5P1(/M) and angle bracket NFL5P2(/M) described below. A 3 m long piezo drive cable (SMC to SMC) as well as a 3 m long feedback cable (LEMO to LEMO) are supplied where applicable. See the Pin Diagrams tab for connector details.

See the Specs tab above for more detailed information on the stages, including compatible controllers. We offer the NFL5DP20(/M) stage bundled with a controller at a discounted price below. See the Bundle tab for more information on this bundle. A power supply is not included; compatible power supplies are sold separately below.

| Item # | NFL5D | NFL5DP20 | NFL5DP20S |

|---|---|---|---|

| Stage Specifications | |||

| Manual Travel Range | 5 mm (0.20") | 5 mm (0.20") | 5 mm (0.20") |

| Maximum Stage Load Capacity | Horizontal: 1 kg (2.2 lbs) Vertical: 0.5 kg (1.1 lbs) |

Horizontal: 1 kg (2.2 lbs) Vertical: 0.5 kg (1.1 lbs) |

Horizontal: 1 kg (2.2 lbs) Vertical: 0.5 kg (1.1 lbs) |

| Stage Mounting Surface Dimensions | 75 mm x 75 mm (2.95" x 2.95") | 75 mm x 75 mm (2.95" x 2.95") | 75 mm x 75 mm (2.95" x 2.95") |

| Stage Height | 30 mm (1.18") | 30 mm (1.18") | 30 mm (1.18") |

| Manual Drive Specifications | |||

| Drive Type | Differential Micrometer | Differential Micrometer | Differential Micrometer |

| Coarse Adjustment Pitch | 0.5 mm | 0.5 mm | 0.5 mm |

| Fine Adjustment Range | 300 µm | 300 µm | 300 µm |

| Fine Adjustment Pitch | 50 µm | 50 µm | 50 µm |

| Piezo Specifications | |||

| Voltage | N/A | 0 to 75 V | 0 to 75 V |

| Position Sensor for Closed-Loop Operation | N/A | N/A | Strain Gauge |

| Travel Range | N/A | 20 µm | 20 µm |

| Theoretical Resolution | N/A | 0.6 nma | 0.6 nma (Closed-Loop Operation) |

| Capacitance | N/A | 3.6 µF | 3.6 µF |

| Connector | N/A | Male SMC | Male SMC |

| Feedback Connector | N/A | N/A | Male 7 Pin LEMO |

| Cable Length | N/A | SMC: 3 m (9.84') | SMC: 3 m (9.84') LEMO: 3 m (9.84') |

| Recommended Controllers | N/A | KPZ101, MDT694B, or MPZ601 | BPC301, MPZ601, or KPZ101 and KSG101 |

Piezo Drive Input

SMC Male

NFL5DP20 and NFL5DP20S

Nominal maximum input voltage: 75 V

Absolute maximum input voltage: 100 V

| Pin | Designation |

|---|---|

| 1 | +15 V |

| 2 | Oscillator + |

| 3 | 0 V |

| 4 | Signal Out - |

| 5 | Signal Out + |

| 6 | -15 V |

| 7 | Travel |

Displacement Sensor

7 Pin LEMO Male

NFL5DP20S Only

| Item # | KPZNFL5(/M) |

|---|---|

| NFL5DP20(/M) Stage Specifications | |

| Drive Type | Differential Micrometer & Piezo |

| Travel Range | 5 mm (0.20") |

| Load Capacity | Horizontal: 1 kg (2.2 lbs) Vertical: 0.5 kg (1.1 lbs) |

| Coarse Adjustment Pitch | 0.5 mm |

| Fine Adjustment Range | 300 µm |

| Fine Adjustment Pitch | 50 µm |

| Piezo Travel Range | 20 µm |

| Piezo Resolution | 0.6 nm |

| Piezo Voltage | 0 to 75 V |

| KPZ101 Controller Specifications | |

| Drive Voltage | 0 to 150 V |

| Drive Current, Max, Continuous | 7.5 mA |

| Stability | 100 ppm Over 24 hrs (After 30 min Warm-Up) |

| Noise | <2 mVRMS |

| Typical Piezo Capacitance | 1 to 10 µF |

| Bandwidth | 1 kHz (1 µF Load, 1 Vp-p) |

| External Input (SMA Male) | 0 to 10 V |

| Output Monitor (SMA Male) | 0 to 10 V |

| USB Port | USB 2.0a |

Stage and Controller Bundle

The KPZNFL5(/M) bundle includes the NFL5DP20(/M) stage, KPZ101 K-Cube piezo controller, USB cable, piezo drive cable, and NFL5P1(/M) mounting plate. The stage provides 5 mm of total translation via a differential micrometer. For finer adjustment, the piezo drive offers 20 µm of translation with 0.6 nm resolution. This bundle is offered at 10% savings over the individual components.

K-Cube Piezo Controller

The KPZ101 can be controlled by its top panel for standalone operation or through its PC interface. The KPZ101 connects to a PC via a mini USB port (USB cable included) and utilizes Thorlabs' Kinesis® software or former generation APT™ software. The Kinesis software features an intuitive graphical user interface (GUI) that allows the unit to be controlled completely via a PC. For more demanding applications, customers can utilize ActiveX® or .NET programming to create their own software for Thorlabs' line of K-Cubes. See the Motion Control Software tab for more information.

Power Supplies

The KPZ101 does not include a power supply as our customers have varying needs. Please see the compatible power supplies below.

Thorlabs offers two platforms to drive our wide range of motion controllers: our Kinesis® software package or the legacy APT™ (Advanced Positioning Technology) software package. Either package can be used to control devices in the Kinesis family, which covers a wide range of motion controllers ranging from small, low-powered, single-channel drivers (such as the K-Cubes™ and T-Cubes™) to high-power, multi-channel, modular 19" rack nanopositioning systems (the APT Rack System).

The Kinesis Software features .NET controls which can be used by 3rd party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications. Low-level DLL libraries are included for applications not expected to use the .NET framework. A Central Sequence Manager supports integration and synchronization of all Thorlabs motion control hardware.

Kinesis GUI Screen

APT GUI Screen

Our legacy APT System Software platform offers ActiveX-based controls which can be used by 3rd party developers working on C#, Visual Basic, LabVIEW™, or any Active-X compatible languages to create custom applications and includes a simulator mode to assist in developing custom applications without requiring hardware.

By providing these common software platforms, Thorlabs has ensured that users can easily mix and match any of the Kinesis and APT controllers in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from single-axis to multi-axis systems and control all from a single, PC-based unified software interface.

The software packages allow two methods of usage: graphical user interface (GUI) utilities for direct interaction with and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

A range of video tutorials is available to help explain our APT system software. These tutorials provide an overview of the software and the APT Config utility. Additionally, a tutorial video is available to explain how to select simulator mode within the software, which allows the user to experiment with the software without a controller connected. Please select the APT Tutorials tab above to view these videos.

Software

Kinesis Version 1.14.25

The Kinesis Software Package, which includes a GUI for control of Thorlabs' Kinesis and APT™ system controllers.

Also Available:

- Communications Protocol

| Posted Comments: | |

Leslie Deck

(posted 2020-10-22 16:43:35.1) Can the NFL5D be upgraded later with a PZT drive? DJayasuriya

(posted 2020-10-23 10:39:06.0) thank you for your inquiry. Yes the NFL5D can be upgrade to a NFL5DP20 (5 mm Travel Translation Stage with Diff. Drive and 20 µm Piezo Actuator). Please get in touch with your local tech support team if you require this change, they will be happy to arrange it. user

(posted 2020-08-31 13:03:36.61) Does the horizontal load also allow a PULL force (i.e. mounted upside down with a hanging load)? DJayasuriya

(posted 2020-09-02 03:51:05.0) Thank you for your inquiry. The load capacity when mounted upside down should be lower than the 0.5 kg that we spec for the upright configuration. The limiting factor is the spring force and the flexure. DJayasuriya

(posted 2020-09-02 03:51:05.0) Thank you for your inquiry. The load capacity when mounted upside down should be lower than the 0.5 kg that we spec for the upright configuration. The limiting factor is the spring force and the flexure. DJayasuriya

(posted 2020-09-02 03:51:05.0) Thank you for your inquiry. The load capacity when mounted upside down should be lower than the 0.5 kg that we spec for the upright configuration. The limiting factor is the spring force and the flexure. David Hoffman

(posted 2020-08-08 18:19:05.157) Hello,

What is the rms position fluctuation in the closed loop operation? Also what is the repeatability of the position command? Thank you DJayasuriya

(posted 2020-08-21 09:31:52.0) Thank you for your inquiry. The position fluctuations when used with closed loop is in the nano meter range theoretically (< 1 nm). The repeatability is similar to our Max stages 30 nm over 30 µm, 0.1 % over full travel range. user

(posted 2020-05-25 06:10:53.02) Hello.

Is there any recommended direction when I use this stage vertically?

In the usage picture, I can find its handle is upright. Can I put the handle downside? DJayasuriya

(posted 2020-05-26 05:11:41.0) Thank you for your inquiry. Yes you would be able to change the orientation of how the stage is mounted. user

(posted 2019-12-19 17:07:03.207) Hi,

Probably a silly question. If I set the two micrometers, then how stable are they afterwards ? Will they drift while I use the piezo drive ? Is it possible to lock the micrometers to stop any drift ?

Thanks ! cwright

(posted 2020-01-06 03:44:03.0) Response from Charles at Thorlabs: Hello and thank you for contacting us. The micrometer on the NFL5DP20/M can be locked by use of a small thumbscrew but only for the course adjustment. The fine adjustment can not be locked on these devices. Unfortunately we do not have any data regarding drift of the micrometer during piezo operation but we would expect only thermal drift to be a factor. ab177

(posted 2018-02-08 18:33:33.537) Hello, I am assembling a multi-stack of translation stages where each has limited load capacity. Could you please tell me what is the weight of the NFL5DP20? Thanks, Art. tfrisch

(posted 2018-02-09 04:22:39.0) Hello, thank you for contacting Thorlabs. We list the weight in the drawing as 0.38kg. I will reach out to you to discuss this application. chiwen.cheng

(posted 2017-09-25 17:43:03.733) We have bought the NFL5DP20S/M and KPZ101. How could we get the relationship between voltage and displacement of Piezo? Do we need another strain gauge (KSG101) to read the real/absolute position? Many thanks AManickavasagam

(posted 2017-09-26 05:38:12.0) Response from Arunthathi at Thorlabs:

Thank you for your question.

Due to hysteresis you will not be able to achieve the Piezo versus displacement relationship. Hence you will need to buy the KSG101 which will measure the position accurately using the inbuilt strain gauge.

Thanks. jp

(posted 2014-06-16 15:31:43.27) Hello, this is Junsong from Royal Institute of Technology, Sweden. How is the relationship between the voltage and the displacement of the Piezo? Is there a equation? For my experiment, I need to know the equation between them. Thanks very much. rcapehorn

(posted 2014-06-17 11:32:34.0) Response from Rob at Thorlabs: Thank you for your question. Due to the inherent nature of piezos having a hysteresis motion, the absolute position cannot be found from the voltage input. To achieve position information you would need to use one of the closed loop versions that uses a strain gauge, NFL5DP20S. I have emailed you with more details if you require. dbcole

(posted 2014-03-07 10:03:24.203) We’re looking to purchase this bundle and had a couple of questions. I’m not a piezo expert, so please forgive my incomplete knowledge. Can the piezo be driven by a sinusoidal signal in order to modulate the position sinusoidally? And if so, is there a maximum drive frequency? Also, can the device displacement be changed in a unidirectional manner over its 20um range at a given linear velocity? cdaly

(posted 2014-03-07 11:52:42.0) Response from Chris at Thorlabs: Thank you for your feedback. Yes, the piezo can be driven with a sinusoidal voltage in order to modulate the displacement, but this will require an input from a 0-10 V analog source such as a function generator or a DAQ card. The maximum frequency would depend on the depth of modulation required (peak to peak voltage) and the capacitance of the stage. For instance, if you were to modulate over the full 150 V (20 um) range of the stage, the maximum frequency would be roughly 8.8 Hz, This can be found using the equation f=I/(pi*V*C), where I is the max current for the controller (7.5mA), V is the voltage range of modulation and C is the capacitance of the stage (1800nF). This value may also be affected by the load present on the stage as well. The displacement of a piezo is inherently mostly linear, but there will be some deviation. jlow

(posted 2012-12-13 09:27:00.0) Response from Jeremy at Thorlabs: Unfortunately this is not possible on the NFL5D. The reason for this is because of the way this stage is designed (it does not have the typical barrel mount). If you are looking for a long travel piezo stage, how about adding on our PAS or PAZ series piezo actuator to our LNR50 series stages? You can find these at http://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=2295. lbassett

(posted 2012-12-07 20:23:24.58) Is it possible to replace the differential adjuster on the NFL5D with a longer-travel piezo actuator such as the DRV181 (80µm) or PAS015 (100µm)? Greg

(posted 2009-01-26 11:31:06.0) Response from Greg at Thorlabs to melsscal: Thank you for taking the time to ask us questions via our website. The PAA100 is a suitable cable for the piezo driver (SMC), while the PAA622 is the strain gauge cable (LEMO). The TPZNF5 (/M) and TSGNF5 (/M) come with the NF5P1 (/M) mounting plate. The T-Cubes come with mounting plates as well. I updated the webpage to clear this up. Also, the bundles are now detailed in tabs so that they are easier to learn about. melsscal

(posted 2009-01-17 09:21:54.0) Does the TSGNF5/M COMES WITH/INCLUDES THREE BASE PLATE LIKE NF5P2 - ONE EACH FOR NF5DP20S 5mm Travel Stage, TPZ001 Piezo Driver & TSG001 Strain Gauge Reader ? melsscal

(posted 2009-01-17 08:25:03.0) waht are the cables part no. which comes along with TSGN5/M as standard accessory ?we want to buy same extra as spare along with TSGN5/M. melsscal

(posted 2009-01-17 08:16:26.0) What are the part nos. of the suitable cables for SMC & LEMO ports of this stage ? |

Manual Linear Translation Stages

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

Crossed-Roller Bearing Stages

These linear translation stages feature crossed roller bearings travel mechanisms for precision motion, high load capacity, and low angular deviation. The LNR Series stages feature all-steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of aluminum.

| Crossed-Roller Bearing Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stages | LX Series 25 mm Stages |

XRN Series 25 mm Stages | XR Series 25 mm Stages | XR Series 50 mm Stages | LNR Series 50 mm Stages |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50 mm (1.97") |

| Drive Type | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 2.34" x 2.36" (59.4 mm x 60.0 mm) |

2.56" x 2.56" (65.0 mm x 65.0 mm) |

2.00" x 3.35" (50.7 mm x 85.0 mm) |

2.98" x 4.33" (75.7 mm x 110.0 mm) |

2.98" x 5.51" (75.7 mm x 140.0 mm) |

3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations |

X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||||

Ball Bearing Stages

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

| Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) |

0.76" x 0.81" (19.3 mm x 20.6 mm) |

2.40" x 2.41" (61.0 mm x 61.2 mm) |

3.00" x 4.00" (76.2 mm x 101.6 mm) |

3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

Dovetail Stages

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

| Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stage | DTS Series 2" Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||

Flexure Stages

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

| Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator |

Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

Vertical Stages

We offer vertical translation stages with crossed roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

| Vertical Stages | ||||

|---|---|---|---|---|

| Product Family | MVS Series 1/2" Vertical Stage | MVS Series 1" Vertical Stage | VAP Series 4" and 10" Vertical Stages | |

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Micrometer | Micrometer | Adjuster Knob and Coarse Manual Positioning | |

| Platform Size | 2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||

Motorized Linear Translation Stages

Thorlabs' motorized linear translation stages are offered in a range of maximum travel distances, from a stage with 20 µm of piezo translation to our 600 mm direct drive stage. Many of these stages can be assembled in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our multi-axis stages, which offer finer adjustment than our standard motorized translation stages. In addition to motorized linear translation stages, we offer motorized rotation stages, pitch and yaw platforms, and goniometers. We also offer manual translation stages.

Piezo Stages

These stages incorporate piezoelectric elements in a variety of drive mechanisms. Our Nanoflex™ translation stages use standard piezo chips along with manual actuators. Our LPS710E z-axis stage features a mechanically amplified piezo design and includes a matched controller. The PD1 stage incorporates a piezo inertia drive that uses "stick-slip" friction properties to obtain an extended travel range. The Elliptec™ stages use resonant piezo motors to push and pull the moving platform through resonant elliptical motion.

| Piezoelectric Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | Nanoflex™ 20 µm Stage with 5 mm Actuator |

Nanoflex™ 25 µm Stage with 1.5 mm Actuator |

LPS710E 1.1 mm Z-Axis Stage |

PD1 20 mm Stage | Elliptec™ 28 mm Stage | Elliptec™ 60 mm Stage |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 20 µm + 5 mm Manual | 25 µm + 1.5 mm Manual | 1.1 mm | 20 mm | 28 mm | 60.0 mm |

| Maximum Velocity | - | - | 3 mm/s | 180 mm/s | 90 mm/s | |

| Drive Type | Piezo with Manual Actuator | Amplified Piezo | Piezoelectric Inertia Drive | Resonant Piezoelectric Motor | ||

| Possible Axis Configurations |

X, XY, XYZ | - | X, XY, XYZ | X | ||

| Additional Details | ||||||

Stepper Motor Stages

These translation stages feature removable or integrated stepper motors and long travel ranges up to 300 mm. The MLJ150 stage also offers high load capacity vertical translation. The other stages can be assembled into multi-axis configurations.

| Stepper Motor Stages | |||||||

|---|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stage |

LNR Series 50 mm Stage |

MLJ150 50 mm Vertical Stage |

NRT Series 100 mm Stage |

NRT Series 150 mm Stage |

LTS Series 150 mm Stage |

LTS Series 300 mm Stage |

| Click Photo to Enlarge |

|

|

|

|

|

|

|

| Travel | 25 mm | 50 mm | 50 mm | 100 mm | 150 mm | 150 mm | 300 mm |

| Maximum Velocity | 2.0 mm/s | 50 mm/s | 3.0 mm/s | 30 mm/s | 50 mm/s | ||

| Possible Axis Configurations |

X, XY, XYZ | X, XY, XYZ | - | X, XY, XYZ | X, XY, XYZ | ||

| Additional Details | |||||||

DC Servo Motor Stages

Thorlabs offers linear translation stages with removable or integrated DC servo motors. These stages feature low profiles and can be assembled in multi-axis configurations.

| DC Servo Motor Stages | |||||

|---|---|---|---|---|---|

| Product Family | MT Series 12 mm Stages | PT Series 25 mm Stages | MTS Series 25 mm Stage | MTS Series 50 mm Stage | KVS30 30 mm Vertical Stage |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 12 mm | 25 mm | 25 mm | 50 mm | 30 mm |

| Maximum Velocity | 2.6 mm/s | 2.4 mm/s | 8.0 mm/s | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | - | ||

| Additional Details | |||||

Direct Drive Stages

These low-profile stages feature integrated brushless DC servo motors for high speed translation with zero backlash. When no power is applied, the platforms of these stages have very little inertia and are virtually free running. Hence these stages may not be suitable for applications where the stage's platform needs to remain in a set position when the power is off. We do not recommend mounting these stages vertically.

| Direct Drive Stages | |||

|---|---|---|---|

| Product Family | DDS Series 220 mm Stage |

DDS Series 300 mm Stage |

DDS Series 600 mm Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 220 mm | 300 mm | 600 mm |

| Maximum Velocity | 300 mm/s | 400 mm/s | 400 mm/s |

| Possible Axis Configurations | X, XY | X | X |

| Additional Details | |||

The stages are supplied with a differential micrometer drive, which provides coarse and fine adjustment. An optional piezo drive is available, with or without strain gauge feedback for closed- and open-loop operation, respectively. The NFL5 series stage is ideal for a variety of applications, including interferometry, microscopy, and other precision nanopositioning applications.

See the Specs tab above for more detailed information, including compatible controllers. We offer the NFL5DP20(/M) stage bundled with a controller at a discounted price below. Compatible power supplies are sold separately below.

- NFL5DP20(/M) NanoFlex™ Flexure Stage Bundled with Piezo Driver and Base Plate

- Includes USB and SMC Cables

- Power Supply Sold Separately Below

- 10% Savings Over Individual Components

The KPZNFL5(/M) bundle includes the KPZ101 K-Cube™ Piezo Driver, the ideal driver for the NFL5DP20(/M) stage, as well as the cables necessary for an open-loop piezo positioning system. The KPZNFL5(/M) bundle also includes a NFL5P1(/M) base plate. Compatible power supplies for the KPZ101 are sold separately below.

Please see the Bundle tab for more information on this bundle.

The NFL5P1 and NFL5P2 are adapter plates designed for the NFL5 Series of translation stages. The NFL5P1 is a universal base plate with slots on the side that enable obstruction-free mounting onto an optical breadboard. This base is ideal for XY or XYZ multi-axis configurations where the standard counterbores in the middle of the stages are obstructed.

The NFL5P2 is an angle bracket that allows a NFL5 Series stage to be mounted vertically in 2-axis and 3-axis configurations.

- Individual ±15 V/5 V Power Supply

- TPS002: For up to Two K-Cubes™ or T-Cubes™ with Mini-DIN Input*

- USB Controller Hubs Provide Power and Communications

- KCH301: For up to Three K-Cubes or T-Cubes

- KCH601: For up to Six K-Cubes or T-Cubes

The TPS002 supplies power for up to two K-Cubes* or T-Cubes. The cubes still require individual computer connection via USB cable.

The KCH301 and KCH601 USB Controller Hubs each consist of two parts: the hub, which can support up to three (KCH301) or six (KCH601) K-Cubes or T-Cubes, and a power supply that plugs into a standard wall outlet. The hub draws a maximum current of 10 A; please verify that the cubes being used do not require a total current of more than 10 A. In addition, the hub provides USB connectivity to any docked K-Cube or T-Cube through a single USB connection.

For more information on the USB Controller Hubs, see the full web presentation.

*The TPS002 can only support one KNA-VIS or KNA-IR controller or one KLD101 driver and should not be used to power any additional units as that may exceed current limitations.

Products Home

Products Home

Zoom

Zoom

5 mm Manual + Optional Piezo

5 mm Manual + Optional Piezo