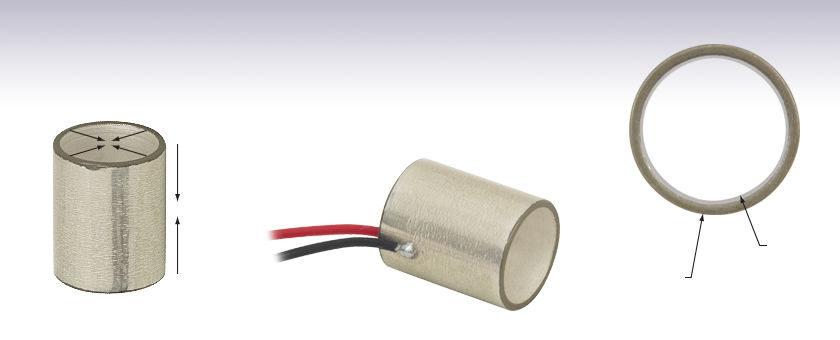

Piezoelectric Tube Actuators

- Axial and Radial Contraction

- Maximum Voltage of 500 V

- 2.8 μm Axial and 1.8 μm Radial Displacement (Free Stroke)

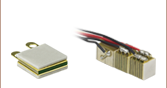

PT49LMW

Piezo Tube,

Pre-Attached 75 mm Wires

PT49LM

Piezo Tube,

Bare Electrodes

Arrows Indicate Directions of Contraction

Top View of the PT49LM

Ø7.0 mm

Positive Electrode

Ø8.0 mm

Negative Electrode

Please Wait

| Piezo Selection Guide |

|---|

| Piezoelectric Ceramic Chips |

| Square |

| Square with Through Hole |

| Round |

| Ring |

| Tube |

| Shear |

| Benders |

| Single-Crystal Piezoelectric Chips |

| Square |

| Piezoelectric Stacks |

| Mounted Piezoelectric Actuators |

| Ultrasonic Piezo Chips & Transducers |

Click to Enlarge

The inner surface of the piezo tube is the positive electrode and should receive a positive voltage.

Features

- Displacement in Axial and Radial Directions

- Actuators with Bare Electrodes or Pre-Attached Wires

- Drive Voltage Range of 0 - 500 V

- For Use in Open-Loop Setups

- Ideal for Vacuum and OEM Applications

- Custom Options Available by Contacting Tech Support

These piezoelectric chips consist of a thin ceramic sheet in a cylindrical shape. They have an outer diameter of 8.0 mm and an inner diameter of 7.0 mm. The piezo tubes provide a maximum displacement of 2.8 µm along the axis of the cylinder and 1.8 µm in the radial direction. The actuators contract in both the radial and axial directions when a positive voltage is applied to the electrodes. The inner surface is the positive electrode that should receive positive bias. In the case of the wired actuators, the wire soldered to the positive electrode is red.

When using these piezos, the load should be mounted on either the curved surface (for radial displacement) or the top and bottom rims (for axial displacement). Do not use with loads mounted to both areas. The radial load should be less than 20 N; exceeding 20 N may cause mechanical failure. In addition, a radial load should only be attached to the central area of the outer surface, at least 1 mm away from the edges. Attaching a radial load to the edges may lead to mechanical failure. For axial loads, try to obtain as large an area of contact as possible on the top and bottom edges of the tube without interfering with the attached wires. See the Operation tab for more information on using these piezoelectric actuators.

Because these piezo elements contract with an applied voltage, applying a pushing load to the piezo enhances the stroke; however, the load negatively influences the recovery. For this reason, we do not specify a load for maximum displacement as with other piezo designs.

The shape of these piezo elements makes them ideal for fiber-stretching and micro-dosing applications.

Piezo Tube Construction and Operation

Piezo tubes are fabricated from a bulk ceramic, which is isostatically pressed together and drilled into tubes. Through a precision grinding process, the accuracy of the height and outer diameter are ensured to better than ±50 µm. The drive voltage is applied to two fired silver electrodes located on the inner and outer walls of the tube.

Piezo chips with custom dimensions, voltage ranges, and coatings are available. Additionally, customers can order these piezo chips in high-volume quantities. Please contact Tech Support for more information.

Click to Enlarge

Dicing the PZT Block into Individual Elements

Click to Enlarge

Chips After Binder Burnout and Sintering

Thorlabs' In-House Piezoelectric Manufacturing

Our piezoelectric chips are fabricated in our production facility in China, giving us full control over each step of the manufacturing process. This allows us to economically produce high-quality products, including custom and OEM devices. A glimpse into the fabrication of our piezoelectric chips follows. For more information about our manufacturing process and capabilities, please see our Piezoelectric Capabilities page.

- Build Blocks from Flexible Sheets of Lead Zirconate Titanate (PZT) Powder

- Screen Print Electrodes on Each Individual Sheet

- Layer the Printed Sheets One Top of Another

- Consolidate the Layered Sheets in an Isostatic Press

- Dice the Block into Individual Elements

- Purge Solvent and Binder Material Residues by Heat Treating the Elements

- Sinter the Elements to Fuse the Piezoelectric Pressed Powder and Grow PZT Crystals

- Lap the Elements to Achieve Tight Dimensional Tolerances: ±5 µm for Each Element

- Screen Print the Outer Electrodes on the Elements

- Align the Individual PZT Crystals Along the Same Axis by Poling the Elements

Operation Notes

Power Connections

A positive bias should be applied across the device. The inner surface is the positive electrode that should receive positive bias, and the outer surface should be connected to ground. Applying a negative bias across the device may cause mechanical failure. For piezos with pre-attached wires, the red wire is attached to the inner, positive electrode, and the black wire is attached to the outer, negative electrode (ground).

Caution: After driving, the piezo is fully charged. Directly connecting the positive and negative electrodes has the risk of electricity discharging, spark, and even failure. We recommend using a resistor (>1 kΩ) between the electrodes to release the charge.

Preloading

The piezo tube exhibits a displacement in both the axial and radial directions. A preload can be applied in either of these orientations, but loads should not be mounted to both simultaneously. Note that the areas near either end of the tube are not strong enough to support a radial load; thus, radial loads should only be applied to the central area of the curved surface, at least 1 mm away from the edges. The radial load should be distributed approximately symmetrically with respect to the plane that bisects the tube's length. When wires are soldered to the inner and outer surfaces, they may interfere with an axial load on the top and bottom of the tube. In this case, try to maintain as large a contact area between the piezo tube and the axial loads as possible.

Soldering Wire Leads to the Electrodes

If wire leads must be reattached to the electrodes, a soldering temperature no higher than 370 °C (700 °F) should be used, and heat should be applied to each electrode for a maximum of 2 seconds. Solder the lead to the middle of the electrode and keep the region over which heat is applied as small as possible.

Interfacing a Piezoelectric Element with a Load

Piezoceramics are brittle and have low tensile strength. Avoid loading conditions that subject the actuator to lateral, transverse, or bending forces. When applied incorrectly, an external load that may appear to be compressive can, through bending moments, cause high tensile stresses within the piezoelectric device. Improperly mounting a load to the piezoelectric actuator can easily result in internal stresses that will damage the actuator. To avoid this, the piezoelectric actuator should be interfaced with an external load such that the induced force is directed along the actuator's axis of displacement. The load should be centered on and applied uniformly over as much of the actuator's mounting surface as possible. When interfacing the flat surface of a load with an actuator capped with a flat mounting surface, ensure the two surfaces are highly flat and smooth and that there is good parallelism between the two when they are mated. To attach a load to the piezo chip, we recommend using an epoxy that cures at a temperature lower than 80 °C (176 °F), such as our 353NDPK or TS10 epoxies or Loctite® Hysol® 9340. Loads should be mounted only to the faces of the piezoelectric chip that translate. Mounting a load to a non-translating face may lead to the mechanical failure of the actuator.

Operating Under High-Frequency Dynamic Conditions

It may be necessary to implement an external temperature-control system to cool the device when it is operated at high frequencies. The maximum operating temperature of these devices is 130 °C (266 °F), and high-frequency operation causes the internal temperature of the piezoelectric device to rise. The dependence of the device temperature on the drive voltage frequency for each product can be accessed by clicking the info icons (![]() ) below. The temperature of the device should not be allowed to exceed its specified maximum operating temperature.

) below. The temperature of the device should not be allowed to exceed its specified maximum operating temperature.

Estimating the Resonant Frequency for a Given Applied Load

A parameter of significance to many applications is the rate at which the piezoelectric actuator changes its length. This dimensional rate of change depends on a number of factors, including the actuator's resonant frequency, the absolute maximum bandwidth of the driver, the maximum current the piezoelectric device can produce, the capacitance of the piezoelectric stack, and the amplitude of the driving signal. The length of the voltage-induced extension is a function of the amplitude of the applied voltage driving the actuator and the length of the piezoelectric stack. The higher the capacitance, the slower the dimensional change of the actuator.

Quick changes in the applied voltage result in fast dimensional changes to the piezoelectric stack. The magnitude of the applied voltage determines the nominal extension of the stack. Assuming the driving voltage signal resembles a step function, the minimum time, Tmin, required for the length of the actuator to transition between its initial and final values is approximately 1/3 the period of resonant frequency. If there is no load applied to the piezoelectric stack, its resonant frequency is ƒo and its minimum response time is:

After reaching this nominal extension, there will follow a damped oscillation in the length of the actuator around this position. Controls can be implemented to mitigate this oscillation, but doing so may slow the response of the actuator.

Applying a load to the actuator will reduce the resonant frequency of the piezoelectric stack. Given the unloaded resonant frequency of the actuator, the mass of the stack, m, and the mass of the load, M, the loaded resonant frequency (ƒo') may be estimated:

Estimating Device Lifetime for DC Drive Voltage Conditions

The lifetime of a piezoelectric device is a function of the operating temperature, applied voltage, and relative humidity conditions. Lifetimes are reduced as a consequence of humidity-driven electrolytic reactions, which occur at the electrodes of the piezoelectric devices when a DC voltage is applied. These reactions both generate hydrogen and result in metal dendrites growing from the cathode towards the anode. The hydrogen liberated by the electrolytic reaction chemically reacts with and degrades the piezoelectric material. Dendrites that grow to electrically connect the cathode and anode result in increasing levels of leakage current. Failed piezoelectric devices are defined as those that exhibit leakage current levels above an established threshold.

A ceramic moisture-barrier layer that insulates Thorlabs' piezoelectric devices on four sides is effective in minimizing the effects of humidity on device lifetime. As there is interest in estimating the lifetime of piezoelectric devices, Thorlabs conducted environmental testing on our ceramic-insulated, low-voltage, piezoelectric actuators. The resulting data were used to create a simple model that estimates the mean time to failure (MTTF), in hours, when the operating conditions of humidity, temperature, and applied voltage are known. The estimated MTTF is calculated by multiplying together three factors that correspond, respectively, to the operational temperature, relative humidity, and fractional voltage of the device. The fractional voltage is calculated by dividing the operational voltage by the maximum specified drive voltage for the device. The factors for each parameter can be read from the following plots, or they may be calculated by downloading the plotted data values and interpolating as appropriate.

In the following trio of plots, the solid-line segment of each curve represents the range of conditions over which Thorlabs performed testing. These are the conditions observed to be of most relevance to our customers. The dotted-line extensions to the solid-line segments represent extrapolated data and represent a wider range of conditions that may be encountered while operating the devices.

Calculation of MTTF to Estimate Lifetimes: MTTF = fV * fT * fH

As an example, when a device of type PK2FSF1 is operated with a voltage of 60 V, at a temperature of 30 °C, and in an environment with 75% relative humidity:

- From the graph below, the voltage factor is 427 (The maximum rated voltage, Vmax, of the PK2FSF1 is 75 V, giving V/Vmax = 60 V / 75 V = 0.80.)

- From the graph at right, the temperature factor is 83

- From the graph at lower-right, the humidity factor is 2.8

Then MTTF = 472 * 83 * 2.8 = 99234.8 hours, which is greater than 11 years.

Note that relationships graphed on this page apply only to Thorlabs' ceramic-insulated, low-voltage, piezoelectric stack actuators.

Click to Enlarge

For an Excel file containing these fH vs. relative humidity data, please click here.

The data used to generate these temperature, voltage, and humidity factor plots resulted from the analysis of measurements obtained from testing devices under six different operational conditions. Different dedicated sets of ten devices were tested under each condition, with each condition representing a different combination of operational voltage, device temperature, and relative humidity. After devices exhibit leakage current levels above a threshold of 100 nA, they are registered as having failed. The individual contributions of temperature, humidity, and voltage to the lifetime are determined by assuming:

- MTTF = fV(V) * fT(T) * fH(H)

- A power law dependence for the voltage: fV(V) = A1Vb1

- An exponential relationship for the relative humidity: fH(T) = A2ecH

- An Arrhenius relationship for the temperature: fT(H) = A3eb2/T

where A1, A2, A3, b1, b2, and c are constants determined through analysis of the measurement data, V is the DC operational voltage, T is the device temperature, and H is the relative humidity. Because the MTTF has a different mathematical relationship with each factor, the dependence of the MTTF on each factor alone may be determined. These are the data plotted above. The regions of the above curves marked by the blue shading are derived from experimental data. The dotted regions of the curves are extrapolated.

Lifetime testing of these devices continues, and additional data will be published here as they become available. To assist in temperature control, please see our selection of thermoelectric coolers. Temperature and humidity can be monitored using our USB Temperature and Humidity Logger.

| Posted Comments: | |

| No Comments Posted |

Products Home

Products Home

Piezo Tube Actuators

Piezo Tube Actuators