Piezoelectric Actuators with Attached Strain Gauges

- Co-Fired and Discrete Stack Options

- Strain Gauges Attached to Actuators in Wheatstone Bridge Circuit Configuration

- Maximum Displacements of 17.4 µm or 38.5 µm for 150 V Maximum Drive Voltage

- Pre-Amplification Circuit Available for Use with Strain Gauge Reader

PZS001

Co-Fired Piezo Stack

17.4 µm Stroke

6.0 mm x 7.0 mm x 20.0 mm

AMP002

Strain Gauge Pre-Amp Circuit

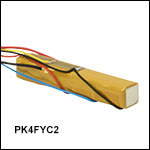

PK4FYC2

Discrete Piezo Stack

38.5 µm Stroke

7.3 mm x 7.3 mm x 36.0 mm

Please Wait

| Piezo Selection Guide |

|---|

| Piezoelectric Ceramic Stacks |

| Discrete, Square |

| Discrete, Square with Through Hole |

| Discrete, Round |

| Discrete, Ring |

| Discrete, Hermetically Sealed |

| Discrete, Shear (1D to 3D Positioners) |

| Co-Fired, Square & Round |

| Co-Fired or Discrete, Square with Strain Gauges |

| Piezoelectric Crystal Stacks |

| Square |

| Piezoelectric Chips |

| Mounted Piezoelectric Actuators |

| Ultrasonic Piezo Chips & Transducers |

Features

- Epoxy-Coated for Protection Against Rough Handling and Mechanical/Chemical Contamination

- Designed for Closed-Loop Operation

- Maximum Displacements of 17.4 µm or 38.5 µm

- 150 V Max Drive Voltage

- Strain Gauge Pre-Amp Circuit Compatible with KSG101 Reader

The PK4FYC2 and PZS001 piezoelectric actuators each include four resistive strain gauges, in a

Wheatstone bridge circuit configuration, bonded directly to piezoelectric actuator. These actuators are designed to be used in a closed-loop system, in which the strain gauge signal is monitored and used to determine the piezo control drive voltage. Compared with open-loop configurations, a closed-loop configuration enables improved control over, and knowledge of, the actuator's displacement during operation. Closed-loop operation is also used to compensate for hysteresis effects.

The four foil-type strain gauges are attached to the durable epoxy resin coating that seals the actuator, and wire leads are soldered to the terminals of the strain gauge circuit. Two gauges are bonded, one next to the other, along one side of the actuator, and the other two gauges are bonded to the opposite side. In each of these pairs of gauges, one is active and one is passive. The active gauge is oriented to maximize its response to the changes in the length of the actuator. The passive gauge is oriented to minimize its response to actuator length variations; it responds primarily to changes in temperature, and its inclusion mitigates temperature-related effects on the strain measurement.

Both actuators have wire leads soldered to the positive and negative electrodes on the actuator. Co-fired piezo actuators are fabricated by interleaving lead zirconate titanate (PZT) layers and electrodes and then sintering the entire structure into a monolithic unit. Discrete-stack piezo actuators are constructed by bonding multiple, individually-sintered, piezoelectric chips together using epoxy and glass beads. Additional differences between the two designs include conductor and insulation details. Please see the Operation tab for more Information.

Thorlabs recommends using the KSG101 strain gauge reader and the AMP002 pre-amplification circuit, sold below, with these piezoelectric actuators.

Integration

For connecting loads to the PZS001, we recommend using a room-temperature epoxy, such as Thorlabs' F120. To mount the PK4FYC2 piezo stack, we recommend using an epoxy that cures at a temperature lower than 80 °C (176 °F), such as our 353NDPK or TS10 epoxies or Loctite® Hysol® 9340. When interfacing a mechanical load with the piezoelectric actuator, it is important to center the mechanical load on the actuator's end face to avoid applying a torque. If the actuator is incorporated into a design that calls for a preload, it is recommended that the preload does not exceed 50% of the specified blocking force. Please refer to the Operation tab above for more information.

The red lead on the piezoelectric actuator must be connected to the high side of the voltage source used to drive the actuator. Do not drive the piezoelectric actuator with a reverse bias voltage, as this could destroy the device. Piezoelectric actuators should not be used in liquid, in the presence of combustible gasses or liquids, or cleaned with organic solvents.

AMP002 Pin Connections

D-type Male

| PIN | Function |

|---|---|

| 1 | Oscillator Input |

| 2 | + 15 V Input Supply |

| 3 | - 15 V Input Supply |

| 4 | 0 V Supply |

| 5 | Amplifier Output |

| 6 | 0 V Supply |

| 7 | ID Resistor Connection |

| 8-9 | N/C |

Operation Notes

Click to Enlarge

Figure 1: Diagram of Piezo Stack Insulation Methods:

(a) In-Chip Insulation Used in Standard Chips and Discrete Stacks,

(b) On-Stack Insulation Used in Co-Fired Stacks

Click to Enlarge

Figure 2: A rod at rest has length L, and strain extends its length by ΔL.

Click to Enlarge

Figure 3: The conductor of a metal foil strain gauge is routed between electrical contat pads in a grid pattern. Force applied along the indicated axis provides maximum response.

Click to Enlarge

Figure 4: The four strain gauges attached to the PK4FYC2 and PZS001 are arranged in a Wheatstone bridge circuit with two active and two passive resistance arms. The passive arms minimize the contribution of temperature changes to the strain measurement. The wire colors above correspond to the PK4FYC2. (The -Vex wire is white on the PZS001.)

Click to Enlarge

Figure 5: In each strain gauge pair, one is active and one is passive. The active gauge is oriented for maximal response to force applied along the indicated axis. The passive gauge has an orthogonal orientation.

Co-Fired Piezo Chips, Co-Fired Piezo Stacks, and Discrete Piezo Stacks

Generally speaking, Thorlabs' co-fired piezo chips and stacks are constructed similarly. In both cases, a structure is built up from alternating electrode layers and green-state lead zirconate titanate (PZT) piezoelectric layers. The assembled structure is then sintered into a single monolithic unit. Supply electrodes of opposite polarity are attached to opposite sides of the structure. Each internal electrode is electrically coupled to one or the other supply electrode, such that no two adjacent internal electrodes have the same polarity. The most significant differences between the co-fired chips and stacks arise from the way each internal electrode is electrically isolated from the supply electrodes of opposite polarity. The different electrical insulation approaches influence the mechanical properties of the actuators. Actuators fabricated using the two different approaches are diagrammed in Figure 1.

In the case of the chips (In-Chip Insulation), the internal electrodes of opposite polarities alternate. Each internal electrode layer is shorter than the full width of the piezo layer. All electrodes of one polarity have edges that are flush with one side of the chip, and all electrodes with the opposite polarity are flush with the opposite side of the chip. Because the electrode does not extend all the way to the opposite edge, the far end of the electrode is completely surrounded by PZT material. The PZT material enclosing the end of the electrode is insulating, which electrically isolates this electrode from the supply electrode of opposite polarity. This approach to electrically insulating the electrodes creates a region of stress at the edge of the electrode. The stress arises both due the abrupt change in thickness on either side of the electrode edge, as well as the tensile stress created when the PZT material sandwiched between electrodes responds to an applied voltage drive signal, but the insulating PZT material beyond the edge of the electrodes does not. This stress limits the maximum height of chips manufactured using this approach. The height of chips are limited to ensure internal stresses are low and do not affect lifetime or performance. Chips are sealed in a ceramic layer that offers superior resistance to humidity and heat than epoxy resin coatings.

One way of increasing the height, and therefore the maximum stroke, of piezo actuators based on these chips is to fabricate discrete piezo stacks. These are manufactured by bonding multiple chips together in series using a glass-bead epoxy. Discrete stacks can be fabricated to substantially longer lengths than co-fired chips or stacks, and this allows them to achieve higher maximum displacements while maintaining sub-millisecond response times and a low drive voltage range. As the constituent chips are sealed within a ceramic barrier layer, discrete stacks have superior resistance to humidity and heat than co-fired stacks, which are sealed in an epoxy resin coating.

In the case of co-fired stacks (On-Stack Insulation), the electrodes extend across the full width of the PZT layers. The edges of the electrodes are flush with all four sides of the stack, including the side with the supply electrode of opposite polarity. The edge of the internal electrode is insulated from that supply electrode by a layer of glass filament applied to the side of the stack. Precision localized application of the glass filament ensures that the electrode edge is electrically isolated from the supply electrode, and that the filament is applied over minimal surface area; the ability of the supply electrode to make electrical connections to the desired internal electrodes is not affected, and the small amount of applied glass filament does not affect the operation of the actuator. With their full-width electrodes, piezo actuators made using this insulating approach are characterized by homogeneous internal stress. Co-fired stacks can therefore be fabricated with greater heights than chips fabricated using the in-chip insulation approach. Co-fired stacks also have a higher percentage of active PZT material than the discrete stacks, which include inactive bonding layers of glass-bead epoxy. They are coated in an epoxy resin.

Making Measurements of Strain Using the Attached Strain Sensor

Strain, ε, is the measure of the deformation of a body due to an applied force, and it is defined as a fractional change in length, L. Referencing Figure 2,

Metal foil strain gauges are frequently chosen to measure small magnitudes of strain, which is expressed in terms of microstrain (µε). Foil gauges are attached to test objects during use. Strain experienced by the object is directly transferred to the strain gauge, resulting in the gauge expanding and contracting with the object. As the electrical resistance of a foil strain gauge varies linearly with the length of its conducting element, monitoring the resistance of the strain gauge provides a means of determining strain. The grid pattern of the conductor, shown in Figure 3, results in maximal deformation of the conductor when tensile or compressive forces are applied along the indicated axis. Orthogonally applied forces have minimal effect on the conductor's dimensions, or the electrical resistance.

Four foil gauges arranged in a Wheatstone bridge circuit configuration, shown in Figure 4, are commonly used to measure small changes in resistance. Each of the four gauges in this voltage divider circuit functions as a separate resistive arm in the Wheatstone bridge. The circuit is operated by applying an excitation voltage, Vex, and measuring the output voltage, Vo, as indicated; the output voltage changes as the resistances in the four arms vary with applied strain.

In the case of the PK4FYC2 and PZS001 piezoelectric actuators, two of the four gauges are bonded, in an adjacent configuration, to one side of the actuator. The other two gauges are similarly bonded to the opposite side of the actuator. One gauge in each pair is oriented so that its active gauge length is aligned with the direction of actuation, and the other is oriented orthogonally, as is diagrammed in Figure 5. The active gauge is the one oriented to respond maximally to changes in the length of the actuator. The other, passive, gauge responds minimally to changes in the length of the actuator; its resistance changes primarily in response to changes in temperature. Both temperature and strain affect the resistance of metal foil gauges, and the inclusion of passive gauges in the circuit is one method used to minimize the effects of temperature changes on the strain measurement.

The sensitivity of the strain gauge, defined as the ratio of the fractional change in electrical resistance, R, to the fractional change in length, is called the gauge factor:

The gauge factor for the PK4FYC2 and PZS001 is 2.

Strain is calculated using the gain factor, excitation voltage, and measured output voltage:

For convenience, wires are attached to the strain gauges' solder tabs during fabrication of the PK4FYC2 and PZS001 piezoelectric actuators. These wires have a gauge of 0.5 mm and are color-coded to identify their function: the red wire is connected to +Vex, the black wire to -Vex, the blue wire to +Vo, and the yellow wire to -Vo.

We recommend using the AMP002 pre-amplification circuit, to amplify the strain sensor signal from the PK4FYC2 and PZS001 piezoelectric actuators before sending it to a strain gauge reader, such as the KSG101. When metal foil gauges are used to measure small changes in strain, it is typical to amplify the sensor signal prior to measuring it.

For additional information describing how metal foil strain gauges are used to measure the strain in the PK4FYC2 and PZS001 piezoelectric actuators, please see our Strain Gauge Tutorial.

Power Connections

A positive bias should be applied across the device using the wires connected to the electrodes. The positive wire should receive positive bias, and the other wire should be connected to ground. Applying a negative bias across the device may cause mechanical failure. The positive wire is red, while the ground wire is black or white.

Interfacing a Piezoelectric Stack with a Load

Piezoceramics are brittle and have low tensile strength. Avoid loading conditions that subject the actuator to lateral, transverse, or bending forces. When applied incorrectly, an external load that may appear to be compressive can, through bending moments, cause high tensile stresses within the piezoelectric device. Improperly mounting a load to the piezoelectric actuator can easily result in internal stresses that will damage the actuator. To avoid this, the piezoelectric actuator should be interfaced with an external load such that the induced force is directed along the actuator's axis of displacement. The load should be centered on and applied uniformly over as much of the actuator's mounting surface as possible. When interfacing the flat surface of a load with an actuator capped with a flat mounting surface, ensure the two surfaces are highly flat and smooth and that there is good parallelism between the two when they are mated. If the external load is directed at an angle to the actuator's axis of displacement, use an actuator fitted with a hemispherical end plate or a flexure joint to achieve safe loading of the piezoelectric stack.

To attach a load to one of our AE series piezo stacks, we recommend using a room-temperature epoxy, such as Thorlabs' F120. For connecting loads to our PC4FL piezo stack, we recommend using an epoxy that cures at a temperature lower than 80 °C (176 °F), such as our 353NDPK or TS10 epoxies or Loctite® Hysol® 9340. Loads should be mounted only to the translating, uncoated faces of the piezoelectric stack; the coated sides of our co-fired piezo stacks do not translate, and mounting a load to a non-translating face may lead to the mechanical failure of the actuator. Our PC4FL Piezo Stack is compatible with the following accessories to minimize internal stress: our PKFESP Ø5 mm Ceramic End Hemispheres (set of 25) and PKFCUP Conical End Cups (set of 10). Some correct and incorrect approaches to interfacing loads with piezoelectric stacks fitted with end plates are discussed in the following.

Click to Enlarge

Figure 6: Actuation of a lever arm using stack fitted with a flat plate (A, Incorrect), and a hemispherical plate (B, Correct).

Click to Enlarge

Figure 7: Loads properly and improperly mounted to PZT actuators using a variety of interfacing methods.

The image at left presents incorrect (A, far-left) and correct (B, near-left) methods for using a piezoelectric stack to actuate a lever arm. The correct method uses a hemispherical end plate so that, regardless of the angle of the lever arm, the force exerted is always directed along the translational axis of the actuator. The incorrect interfacing of the stack and the lever arm, shown at far-left, endangers the stack by applying the full force of the load to one edge of the stack. This uneven loading causes dangerous stresses in the actuator, including a bending moment around the base.

The image at right shows one incorrect (near-right, A) and three correct approaches for interfacing a flat-bottomed, off-axis load with a piezoelectric stack. Approaches A and B are similar to the incorrect and correct approaches, respectively, shown in the image at left. Correct approach C shows a conical end cup, such as the PKFCUP, acting as an interface. The flat surface is affixed to the mating surface of the load, and the concave surface fits over the hemispherical dome of the end plate. In the case of correct approach D, a flexure mount acts as an interface between the off-axis flat mounting surface of the load and the flat mounting plate of the actuator. The flexure mount ensures that the load is both uniformly distributed over the surface plate of the actuator and that the loading force is directed along the translational axis of the actuator.

Operating Under High-Frequency Dynamic Conditions

It may be necessary to implement an external temperature-control system to cool the device when it is operated at high frequencies. High-frequency operation causes the internal temperature of the piezoelectric device to rise. The dependence of the device temperature on the drive voltage frequency for select products can be found in the Spec Sheet accessed by clicking the red Docs icon (![]() ) below. The temperature of the device should not be allowed to exceed its specified maximum operating temperature.

) below. The temperature of the device should not be allowed to exceed its specified maximum operating temperature.

Estimating the Resonant Frequency for a Given Applied Load

A parameter of significance to many applications is the rate at which the piezoelectric actuator changes its length. This dimensional rate of change depends on a number of factors, including the bandwidth of the piezoelectric actuator (its resonant frequency), the absolute maximum bandwidth of the driver (its slew rate), the maximum current the piezoelectric device can produce, the capacitance of the piezoelectric stack, and the amplitude of the driving signal. The length of the voltage-induced extension is a function of the amplitude of the applied voltage driving the actuator and the length of the piezoelectric stack. The higher the capacitance, the slower the dimensional change of the actuator.

Quick changes in the applied voltage result in fast dimensional changes to the piezoelectric stack. The magnitude of the applied voltage determines the nominal extension of the stack. Assuming the driving voltage signal resembles a step function, the minimum time, Tmin, required for the length of the actuator to transition between its initial and final values is approximately 1/3 the period of resonant frequency. If there is no load applied to the piezoelectric stack, its resonant frequency is ƒo and its minimum response time is:

After reaching this nominal extension, there will follow a damped oscillation in the length of the actuator around this position. Controls can be implemented to mitigate this oscillation, but doing so may slow the response of the actuator.

Applying a load to the actuator will reduce the resonant frequency of the piezoelectric stack. Given the unloaded resonant frequency of the actuator, the mass of the stack, m, and the mass of the load, M, the loaded resonant frequency (ƒo') may be estimated:

Piezo Driver Bandwidth Tutorial

Knowing the rate at which a piezo is capable of changing lengths is essential in many high-speed applications. The bandwidth of a piezo controller and stack can be estimated if the following is known:

- The maximum amount of current the controllers can produce. This is 0.5 A for our BPC Series Piezo Controllers, which is the driver used in the examples below.

- The load capacitance of the piezo. The higher the capacitance, the slower the system.

- The desired signal amplitude (V), which determines the length that the piezo extends.

- The absolute maximum bandwidth of the driver, which is independent of the load being driven.

To drive the output capacitor, current is needed to charge it and to discharge it. The change in charge, dV/dt, is called the slew rate. The larger the capacitance, the more current needed:

For example, if a 100 µm stack with a capacitance of 20 µF is being driven by a BPC Series piezo controller with a maximum current of 0.5 A, the slew rate is given by

Hence, for an instantaneous voltage change from 0 V to 75 V, it would take 3 ms for the output voltage to reach 75 V.

Note: For these calculations, it is assumed that the absolute maximum bandwidth of the driver is much higher than the bandwidths calculated, and thus, driver bandwidth is not a limiting factor. Also please note that these calculations only apply for open-loop systems. In closed-loop mode, the slow response of the feedback loop puts another limit on the bandwidth.

Sinusoidal Signal

The bandwidth of the system usually refers to the system's response to a sinusoidal signal of a given amplitude. For a piezo element driven by a sinusoidal signal of peak amplitude A, peak-to-peak voltage Vpp, and frequency f, we have:

A diagram of voltage as a function of time is shown to the right. The maximum slew rate, or voltage change, is reached at t = 2nπ, (n=0, 1, 2,...) at point a in the diagram to the right:

From the first equation, above:

Thus,

For the example above, the maximum full-range (75 V) bandwidth would be

.

.

For a smaller piezo stack with 10 times lower capacitance, the results would be 10 times better, or about 1060 Hz. Or, if the peak-to-peak signal is reduced to 7.5 V (10% max amplitude) with the 100 µm stack, again, the result would be 10 times better at about 1060 Hz.

Triangle Wave Signal

For a piezo actuator driven by a triangle wave of max voltage Vpeak and minimum voltage of 0, the slew rate is equal to the slope:

![]() .

.

Or, since f = 1/T:

Square Wave Signal

For a piezo actuator driven by a square wave of maximum voltage Vpeak and minimum voltage 0, the slew rate limits the minimum rise and fall times. In this case, the slew rate is equal to the slope while the signal is rising or falling. If tr is the minimum rise time, then

or

.

.

For additional information about piezo theory and operation, see the Piezoelectric Tutorials page.

| Posted Comments: | |

| No Comments Posted |

- Durable Epoxy Resin Coating

- Ceramic End Pates

- 38.5 µm Maximum Displacement

- 5.0 mm x 5.0 mm Active Piezo Cross Section

- Strain Gauge Circuit Configuration Minimzes Thermal Effects on Strain Measurement

The PK4FYC2 consists of the PK4FYP2 discrete-stack piezoelectric actuator with an attached full bridge strain gauge. The full bridge strain gauge is made by connecting four metallic foil strain gauges in a Wheatstone bridge configuration. Each individual strain gauge has a resistance of 350 Ω and a gauge factor of two. The feedback from the strain gauge can be used by a strain gauge controller to provide linear operation of the piezo-electric actuator. In order to use a strain gauge reader like the KSG101 to monitor the feedback, the strain gauge must first be connected to a pre-amplification circuit like the AMP002 listed below. A 3 kΩ resistor, which is needed to properly interface the AMP002 with the PK4FYC2, is included with the PK4FYC2. Use of the resistor is described in the AMP002's manual.

Wires are attached to the actuator's electrodes and the electrical connections on the strain gauge circuit. The wires attached to the actuator's electrodes are larger in diameter than the wires attached to the strain gauges. The red and black strain gauge leads are used to supply the input (bridge excitation) voltage to the strain gauge. The blue and yellow strain gauge leads wires are used to monitor the output voltage of the strain gauge. For more information, please see the Operation tab.

After driving, the piezo is fully charged. Directly connecting the red and black wires has the risk of electricity discharging, spark, and even failure. We recommend using a resistor (>1 kΩ) between the red and black wires to release the charge.

- Durable Epoxy Resin Coating

- 17.4 µm Maximum Displacement

- 5.0 mm x 5.0 mm Active Piezo Cross Section

- Strain Gauge Configuration Minimzes Thermal Effects on Strain Measurement

The PZS001 consists of a 17.4 µm travel, co-fired piezoelectric actuator with an attached full bridge strain gauge. The full bridge strain gauge is made by connecting four metallic foil strain gauges in a Wheatstone bridge configuration. Each individual strain gauge has a resistance of 350 Ω and a gauge factor of two. The feedback from the strain gauge can be used by a strain gauge controller to provide linear operation of the piezo-electric actuator. In order to use a strain gauge reader like the KSG101 to monitor the feedback, the strain gauge must first be connected to a pre-amplification circuit like the AMP002 listed below. No resistor is needed to interface the PZS001 with the AMP002.

Wires are attached to the actuator's electrodes and the electrical connections on the strain gauge circuit. The wires attached to the actuator's electrodes are larger in diameter than the wires attached to the strain gauges. The red and black strain gauge leads are used to supply the input (bridge excitation) voltage to the strain gauge. The blue and yellow strain gauge leads wires are used to monitor the output voltage of the strain gauge. For more information, please see the Operation tab.

A pre-amplification circuit like the AMP002 is required to amplify the strain signal input into the strain gauge reader in most cases; when the measured strain is a very small quantity, as is the case for the strain gauge circuits attached to the PZS001 and PK4FYC2, the output signal is also small, and a pre-amplification circuit is a typical requirement.

The AMP002 is a pre-amplification circuit for full bridge strain gauges that also features a removable cover. The printed circuit board measures 1.6" x 2.25" (41 mm x 57 mm) and has four solder points for the full bridge strain gauge leads and a 9-pin D-type connector for connecting to a strain gauge reader. The cable required to connect the circuit to the KSG101 stand-alone strain gauge reader or the BPC Series of controllers is also included. The circuit contains two resistive pots, one to continuously vary the circuit's gain from 1 to 10,000 and the other to apply a DC offset that can be used to balance the full bridge strain gauge. This unit provides the required input voltage to the strain gauge circuit when connected to a Thorlabs strain gauge reader.

Depending on the maximum displacement of the piezo actuator, a resistor (R6) may be required to interface the actuator with the AMP002. The manual for the AMP002 contains a circuit diagram and a reference table describing how to choose and where to connect this resistor, if required. No resistor is required to interface the PZS001 with the AMP002. The PK4FYC2 includes the 3 kΩ resistor that is required to interface the PK4FYC2 with the AMP002.

Products Home

Products Home

Zoom

Zoom

Piezo Stacks with Strain Gauges

Piezo Stacks with Strain Gauges