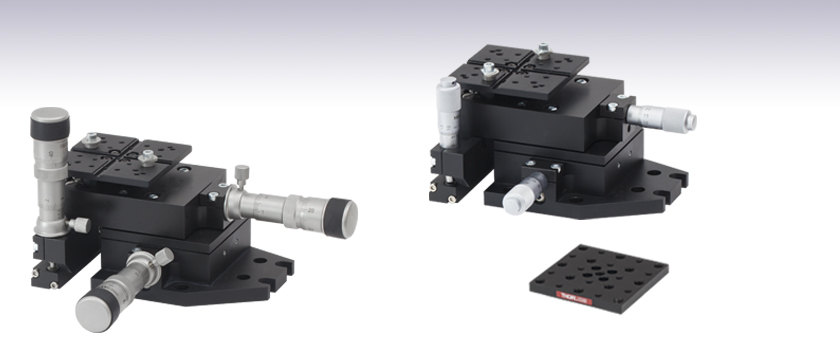

3-Axis RollerBlock™ Long-Travel Stages

- 13 mm (1/2") of X, Y, and Z Travel

- Crossed Roller Bearing Design for Maximum Rigidity

- Modular High-Resolution Drive Options

RBL13D

Differential Micrometer Drives

RB13P1

Additional Top Plate for Off-Center and General Optics Mounting

RB13M

Micrometer Drives

Please Wait

Click to Enlarge

Our Rollerblock stages can be upgraded with our ZFS13B Stepper Motor Actuators to achieve a theoretical resolution of 0.46 nm. For more information concerning compatible actuators, please see the Drives tab.

Click to Enlarge

The Top Plate can be Removed and Replaced with the RB13P1 for Off-Center Mounting and General Optics Mounting

Features

- 13 mm (1/2") of X, Y, and Z Travel

- Micrometer Driven or Differential Micrometer Driven Options

- Crossed Roller Bearing Design Ensures Smooth Continuous Motion and High Load Capacity

- Grooved Top Plate Ensures Alignment of Multi-Axis Stage Accessories

- All Adjusters Coupled to the Base to Minimize Crosstalk

- Compatible with Ø9.5 mm Barrel Actuators (See Drives Tab)

- Available in Right-Handed Versions

- Left-Handed and Custom Drive Configurations are Available; Contact Tech Support for Details

Thorlabs' 3-Axis RollerBlock™ Long-Travel Stages incorporate a crossed roller bearing design that provides up to 13 mm (1/2") of X, Y, and Z travel. This design, along with a combination of steel and aluminum construction, also allows for a high load capacity of 4.4 kg (9.7 lbs) while maintaining the sub-micron resolution provided by the included high-precision differential or standard micrometers. The bearings are all strategically located within the stage for increased protection from contamination, enhancing the product lifetime of the stage when compared to designs with exposed bearing surfaces. Compared to translation stages constructed from stacking single axis stages, the unibody approach used in these stages offers a smaller overall footprint.

Both the RBL13D(/M) long-travel stage with differential micrometers and RB13M(/M) long-travel stage with micrometer drives have a nominal deck height of 62.5 mm (2.46"). This allows a longer travel stage to be incorporated into complex optical systems built around our precision 3-axis MicroBlock compact flexure stages and NanoMax flexure stages, as shown in the image below.

Custom Configurations

We can also supply each stage in left hand configurations, or without drives for fitting third party actuators or our selection of alternative actuators (see Drives tab). For special requirements to meet the needs of your specific application, please contact Tech Support.

Click to Enlarge

The nominal 62.5 mm (2.46") deck height of our Rollerblock Stages matches that of our 3-Axis Nanomax Stages, allowing for long-travel fiber and optoelectronic alignments with piezo control.

Precision Drives

Three clamps, one for each axis of travel, allow for the attachment of any actuator with a Ø9.5 mm (Ø3/8") mounting barrel. Hence, the included actuators can be removed and replaced with motorized or piezo assisted drives. For a full listing of compatible actuators, please see the Drives tab.

Easy Alignment of Accessories

The top platform features four 4-40 (M2), sixteen 6-32 (M3), and nine 8-32 (M4) mounting holes with two 3 mm wide central keyways for rapid system reconfiguration while maintaining accessory alignment (see the image to the left). Click the blue info icon (![]() ) in the table to the right for the mounting hole layout. The crossed pattern allows for both right- and left-handed versions of the stage to be used. A wide range of accessories is available to mount items such as microscope objectives, collimation packages, wave guides, fiber, and much more. If options are required for off-center mounting of components, the grooved top plate can be replaced with the RB13P1 adapter plate (sold at the bottom of this page), which has an array of 1/4"-20 (M6) and 8-32 (M4) mounting holes.

) in the table to the right for the mounting hole layout. The crossed pattern allows for both right- and left-handed versions of the stage to be used. A wide range of accessories is available to mount items such as microscope objectives, collimation packages, wave guides, fiber, and much more. If options are required for off-center mounting of components, the grooved top plate can be replaced with the RB13P1 adapter plate (sold at the bottom of this page), which has an array of 1/4"-20 (M6) and 8-32 (M4) mounting holes.

| Multi-Axis Stage Accessories | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

| Fiber Mounts |

Fiber Rotators |

Waveguide Mounts |

Diode Mounts |

Fixed Mounts |

Kinematic Mounts |

Top Plates |

Extension Platforms |

Fiber Chucks |

Slide Holders |

Kinematic Platforms |

Adapter Plates |

Click to Enlarge

DRV517 Piezo Actuator with Differential Micrometer Mounted to the x-axis of a RB13M Rollerblock Stage

Modular Drive Options

All 3-Axis Rollerblock stages have a modular design that allows the drives to be removed and replaced at any time by loosening the two cap screws above the barrel of the mounted actuator. Actuators with a Ø9.5 mm (Ø3/8") barrel, shown below, can be mounted on each axis of a Rollerblock stage. This allows for mix-and-match customization of actuators depending on the amount of automation or resolution needed on each axis.

The drives compatible with our 3-axis Rollerblock Long-Travel Stages are summarized below. For more detailed information on each drive, please see the full presentation for our Stepper Motor Drive, Differential Micrometers, Micrometers or Piezo Actuators. Please note that we do not recommend drives with rotating tips for our RollerBlock stages due to increased wear of the contact pads.

| Item # | 148-801STa | 148-801ST-H | DRV304b | DRV517c | ZST213B | ZFS13B |

| Click Image to Enlarge |

|

|

|

|

|

|

| Actuator Type | Micrometer | Differential Micrometer | Feedback Piezo with Differential Micrometer |

Stepper Motor | Compact Stepper Motor |

|

| Mounting Barrel Diameter | Ø9.5 mm (Ø3/8") | |||||

| Travel Range | 13 mm (1/2") | Coarse: 1/2" (13 mm) Fine: 300 µm |

Micrometer: 13 mm (1/2") Piezo: 30 µm |

13 mm (1/2") | 13 mm (1/2") | |

| Adjustment | 500 µm/revolution | Coarse: 500 µm/revolution Fine: 50 µm/revolution |

Micrometer: 60 µm/revolution | 22.6 µm/revolution | ||

| Resolution | 5 µm | Coarse: 5.0 µm Fine: 0.5 µm |

Micrometer: 1 µm Piezo: 10 nm |

0.5 nm | 0.46 nm | |

| Compatible Controllers | - | Benchtop: BPC300 Series K-Cubes: KPZ101 with KSG101 |

K-Cube: KST101 | K-Cube: KST101 | ||

Multi-Axis Stage Selection Guide

Click to Enlarge

In the above application, a 3-Axis NanoMax flexure stage is aligned in front of a 6-axis stage at the proper 112.5 mm deck height using an AMA554 Height Adapter.

3-Axis Stages

Thorlabs offers three different 3-Axis Stage variations: NanoMax flexure stages, MicroBlock compact flexure stages, and RollerBlock long-travel stages. Each stage features a 62.5 mm nominal deck height. Our NanoMax line of 3-axis stages offers built-in closed- and open-loop piezos as well as modular drive options that include stepper motors, differential drives, or additional piezos. The MicroBlock stages are available with differential micrometer drives or fine thread thumbscrews; these drives are not removable. Finally, our RollerBlock stage drivers can be switched out for any actuator that has a Ø3/8" (9.5 mm) mounting barrel.

4- and 5-Axis Stages

Our 4- and 5-axis stages are ideal for the static positioning of waveguides or complex optical elements with respect to our 3-axis or 6-axis high-performance alignment stages. Thorlabs' 5-axis stages have nominal heights of 62.5 mm or 112.5 mm. The AMA554 Height Adapter can be used to raise the deck height of the 3-axis or 4-axis stages to 112.5 mm for compatibility with our 5-axis MicroBlock or 6-Axis NanoMax Stages.

6-Axis Stages

Thorlabs' 6-Axis NanoMax Nanopositioners are ideal for complex, multi-axis positioning and have a nominal deck height of 112.5 mm. These stages offer a common point of rotation and a patented parallel flexure design that allows all actuators to be coupled directly to the base to minimize any unwanted motion in the system. Built-in closed- and open-loop piezo options are available. A selection of modular drive options allows any axis to be manual or motorized with the option for external piezos. Our units without included actuators are also available in right- or left-handed configurations. To increase the stage height of the 3-axis stages to 112.5 mm, we recommend our AMA554 Height Adapter, shown in the image to the right.

A complete selection and comparison of our multi-axis stages is available below.

3-Axis Stages

| Item # | MAX313D | MAX312D | MAX311D | MAX383 | MAX381 | MAX303 | MAX302 | MAX301 | MBT602 | MBT616D | RB13M | RBL13D | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stage Type | NanoMax Flexure Stages | MicroBlock Compact Flexure Stages |

RollerBlock Long Travel Stages | |||||||||||||||||

| Included Drives | DRV3 Differential Micrometers | DRV208 Stepper Motor Actuators | N/A | Fine Thread Thumbscrews | Differential Micrometers | 148-801ST Micrometer Drives |

DRV304 Differential Micrometers |

|||||||||||||

| Built-in Piezos | N/A | Open Loop |

Closed Loop | N/A | Closed Loop | N/A | Open Loop | Closed Loop | N/A | N/A | ||||||||||

| Travel (X, Y, Z) | 4 mm (0.16") | 13 mm (0.51") | ||||||||||||||||||

| Deck Height (Nominal) | 62.5 mm (2.46") | |||||||||||||||||||

| Optical Axis Height (Nominal) | 75 mm (2.95") | |||||||||||||||||||

| Load Capacity (Max) | 1 kg (2.2 lbs) | 4.4 kg (9.7 lbs) | ||||||||||||||||||

| Thermal Stability | 1 µm/°C | - | ||||||||||||||||||

| Weight | 1.00 kg (2.20 lbs) | 0.64 kg (1.40 lbs) | 0.59 kg (1.30 lbs) | |||||||||||||||||

4-Axis Stages

| Item # | MBT401D MBT401D/M |

MBT402D MBT402D/M |

|

|---|---|---|---|

| Stage Type | 4-Axis Thin-Profile MicroBlock Device Stage | 4-Axis Low-Profile MicroBlock Device Stage | |

| Included Drives | Differential Micrometers | ||

| Built-in Piezos | N/A | ||

| Travel | Horizontal Axis (Y)a | 13 mm (0.51") | |

| Vertical Axis (Z) | 6 mm (0.24") | ||

| Pitch (θy) | ±5° | ||

| Yaw (θz) | ±5° | ||

| Deck Height (Nominal) | 62.5 mm (2.46") | ||

| Optical Axis Height (Nominal) | 75 mm (2.95") | ||

| Load Capacity (Max) | 0.5 kg (1.1 lbs) | ||

5-Axis Stages

| Item # | MBT401D (MBT401D/M) or MBT402D (MBT402D/M) with MBT501 |

PY005 | |

|---|---|---|---|

| Stage Type | 5-Axis MicroBlock Stage System | Compact 5-Axis Stage | |

| Included Drives | Differential Micrometers | 100 TPI Actuators | |

| Built-in Piezos | N/A | ||

| Travel | Optical Axis (X) | 13 mm (0.51") | 3 mm (0.12") |

| Horizontal Axis (Y) | 13 mm (0.51") | 3 mm (0.12") | |

| Vertical Axis (Z) | 6 mm (0.24") | 3 mm (0.12") | |

| Pitch (θy) | ±5° | ±3.5° | |

| Yaw (θz) | ±5° | ±5° | |

| Deck Height (Nominal) | 112.5 mm (4.43") | 62.5 mm (2.46")a | |

| Optical Axis Height (Nominal) | 125 mm (4.92") | 75 mm (2.95")a | |

| Load Capacity (Max) | 0.5 kg (1.1 lbs) | 0.23 kg (0.5 lbs) | |

6-Axis Stages

| Item # | MAX601D MAX601D/M |

MAX602D MAX602D/M |

MAX603D MAX603D/M |

MAX681 MAX681/M |

MAX682 MAX682/M |

MAX683 MAX683/M |

MAX607 MAX607/M MAX607La MAX607L/Ma |

MAX608 MAX608/M MAX608La MAX608L/Ma |

MAX609 MAX609/M MAX609La MAX609L/Ma |

|

|---|---|---|---|---|---|---|---|---|---|---|

| Stage Type | 6-Axis NanoMax Flexure Stage | |||||||||

| Included Drives | DRV3 Differential Micrometers | DRV208 Stepper Motor Actuators | N/A | |||||||

| Built-in Piezos | N/A | Open Loop | Closed Loop | N/A | Open Loop | Closed Loop | N/A | Open Loop | Closed Loop | |

| Travel | X, Y, Z | 4 mm (0.16") | ||||||||

| θx, θy, θz | 6° | |||||||||

| Deck Height (Nominal) | 112.5 mm (4.43") | |||||||||

| Optical Axis Height (Nominal) | 125 mm (4.92") | |||||||||

| Load Capacity (Max) | 1.0 kg (2.2 lbs) | |||||||||

| Posted Comments: | |

lifeng.chen

(posted 2015-07-21 15:13:45.61) Hi, since your description only tells on axis loads maximum for 4.4kg, I want to know what is the maximum load for other axis. I would flip and stand it vertically and attach components in that way, weight about 1-2kg (not sure). Thanks in advance. Lifeng Chen bhallewell

(posted 2015-07-27 03:36:00.0) Response from Ben at Thorlabs: Thank you for your question. The RollerBlock 3-axis stage was engineered to operate explicitly in a tabletop mounted orientation, however I will liase with our design engineers to discuss your application with them. I will contact you directly to obtain further details. hendrik.seitz

(posted 2013-10-30 15:49:00.343) Dear Sir oder Madam,

I have got a question concerning the RollerBlock RB13M/M. I'd like to use the RB13M/M for aligning a copper block with a 10 cm x 20 cm surface and a weight of 2.5 kg. The top plate of the RB13M/M has only an 6 cm x 6 cm surface and cannot be placed directly under the middle of the copper block because of the z micrometer drive. So my question is, if the RB13M/M might get damaged because of the overlap of the copper block and the so resulting torque.

Looking forward to your reply,

yours sincerely,

Hendrik Seitz msoulby

(posted 2013-11-04 05:29:27.0) Response from Mike at Thorlabs: We only specify a load capacity for on axis loads for these stages which is 4.4kg. However small or counter balanced off axis loads can still be mounted to these stages. The crossed roller bearings used in these stages help prevent unwanted movement in the top plate. I would recommend that the long 20cm side of your plate is balanced evenly over the top plate and the shorter side is the side that is unbalanced this will help minimise any torque that the top plate might experience. |

| Item # | RBL13D(/M) | |

|---|---|---|

| Travel Mechanism | Crossed Roller Bearings | |

| Deck Height (Nominal) | 62.5 mm (2.46") | |

| Optical Axis Height (Nominal) | 75 mm (2.95") | |

| Load Capacity (Max) | 4.4 kg (9.7 lbs) | |

| Mounting Barrel Size | Ø9.5 mm (Ø3/8") | |

| Pitch and Yaw Runouta | X Motion: ±125 µrad Y Motion: ±75 µrad Z Motion: ±150 µrad |

|

| Straightness | ±10 µm | |

| Drive Specifications | ||

| Travel Range | Coarse | 13 mm (1/2") |

| Fine | 300 μm | |

| Resolution | Coarse | 5.0 μm |

| Fine | 0.5 μm | |

| Coarse Adjustment (with Vernier Scale) |

500 μm/rev | |

| Fine Adjustment (with Vernier Scale) |

50 μm/rev | |

- Preconfigured with DRV304 Differential Micrometers for Manual Adjustments

- Mounting Barrel Allows Drives to be Removed and Replaced

- Mounting Holes and Slots in Base Allow for Attachment to Breadboards and Optical Tables

- Left Handed Version Available, Contact Tech Support

- Other Manual and Motorized Drive Options Available, Please See the Drives Tab for Details

Click to Enlarge

Graduations on the Differential Micrometers for Absolute Positioning

Thorlabs' Rollerblock long-travel stage with differential micrometers provides 13 mm (1/2") of coarse travel and 300 µm of fine travel. The coarse adjuster has a Vernier scale with 10 µm graduations for a resolution of 5 µm. The fine adjuster has a Vernier scale with 1 µm graduations allowing for a resolution of 0.5 µm. This resolution and long-travel range make these stages ideal for optimizing the coupling efficiency in a fiber alignment or waveguide positioning system. The graduations also allow for a clear reference point for absolute positioning within a system. The modular design of the included drives allows them to be replaced at any time; please see the Drives tab for more details and our full selection of compatible actuators.

Imperial stages come with an MMP1 Top Plate, while metric stages come with an MMP1/M Top Plate. These mounting plates contain a central keyway that allows for easy and repeatable alignment of all of the accessories listed in the overview. If off-center or breadboard mounting is necessary, we also offer the RB13P1 Top Plate.

| Item # | RB13M(/M) |

|---|---|

| Travel Mechanism | Crossed Roller Bearings |

| Deck Height (Nominal) | 62.5 mm (2.46") |

| Optical Axis Height (Nominal) | 75 mm (2.95") |

| Load Capacity (Max) | 4.4 kg (9.7 lbs) |

| Mounting Barrel Size | Ø9.5 mm (Ø3/8") |

| Pitch and Yaw Runouta | X Motion: ±125 µrad Y Motion: ±75 µrad Z Motion: ±150 µrad |

| Straightness | ±10 µm |

| Drive Specifications | |

| Travel Range | 13 mm (1/2") |

| Resolution | 5.0 μm |

| Coarse Adjustment (with Vernier Scale) |

500 μm/rev |

- Preconfigured with Three 148-801ST Micrometers for Manual Adjustments

- Mounting Barrel Allows Drives to be Removed and Replaced

- Mounting Holes and Slots in Base Allow for Attachment to Breadboards and Optical Tables

- Left Handed Version Available, Contact Tech Support

- Other Manual and Motorized Drive Options Available, Please See the Drives Tab for Details

Thorlabs' Rollerblock long-travel stage with micrometers provides 13 mm (1/2") of coarse travel. The coarse adjuster has a Vernier scale with 10 µm graduations for a resolution of 5 µm. This resolution and long-travel range make these stages ideal for optimizing the coupling efficiency in a fiber alignment or waveguide positioning system. The graduations also allow for a clear reference point for absolute positioning within a system. The modular design of the included drives allows them to be replaced at any time; please see the Drives tab for more details and our full selection of compatible actuators.

Imperial stages come with an MMP1 Top Plate, while metric stages come with an MMP1/M Top Plate. These mounting plates contain a central keyway that allows for easy and repeatable alignment of all of the accessories listed in the overview. If off-center or breadboard mounting is necessary, we also offer the RB13P1 Top Plate.

Click to Enlarge

RB13P1 Top Plate Shown Replacing the MMP1 Crossed Groove Mounting Plate on an MAX311D Flexure Stage

- RB13P1 Adapter Plate for General Purpose Accessories and Components

- Array of Thirteen 1/4"-20 (M6) and Twelve 8-32 (M4) Tapped Mounting Holes

- MMP1 Standard 3-Axis Stage Top Plate (Included with All 3-Axis Stages)

- Two 3 mm Wide Central Keyways for Aligning Multi-Axis Stage Accessories

- Sixteen 6-32 (M3) Taps for Mounting Cleats

- Four 4-40 (M2) Taps

- Nine 8-32 (M4) Taps

The RB13P1(/M) Adapter Plate is designed as a replacement option for the standard MMP1(/M) grooved top plate sold with the stages above. Four counterbores that accept M3 screws allow it to be attached to the above stages. The 2.36" x 2.36" mounting surface is the same as the MMP1(/M) top plate that is included with the above stages. For complete details on the dimensions and tap locations of this top plate, please see the mechanical drawings below.

The MMP1(/M) Top Plate is included with the stages sold above but can be purchased separately as well. This plate features two 3 mm wide central keyways in a crossed pattern to allow for rapid configuration while maintaining accessory alignment, making this plate ideal for fiber launch applications. This "crossed groove" design allows for the NanoMax stages to be used in a left- or right-handed configuration. The plate also contains an array of 4-40 (M2), 6-32 (M3), and 8-32 (M4) tapped mounting holes for securing and mounting various components. For complete details on the dimensions and tap locations of this plate, please see the mechanical drawings.

Products Home

Products Home

Zoom

Zoom

13 mm Crossed-Roller Bearing Stages (RollerBlock)

13 mm Crossed-Roller Bearing Stages (RollerBlock)