1x4 Single Mode Fiber Optic Couplers

- Wavelengths from 560 nm to 1550 nm Available

- 25:25:25:25 Split Ratio

- 2.0 mm Narrow Key FC/PC or FC/APC Connectors

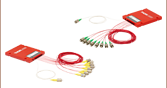

TWQ1550HA

1550 nm 1x4 Wideband Coupler, FC/APC Connectors

TNQ1064AHF

1064 nm 1x4 Narrowband Coupler, FC/PC Connectors

Use for Splitting Signals

Please Wait

| 1x4 Single Mode Fiber Optic Couplersa | |

|---|---|

| Center Wavelength | Bandwidth |

| 405 nm | ±5 nm |

| 560 nm | ±50 nm |

| 630 nm | ±15 nm |

| 850 nm | ±100 nm |

| 1064 nm | ±15 nm |

| 1064 nm | ±100 nm |

| 1300 nm | ±100 nm |

| 1310/1550 nm | ±40 nm |

| 1550 nm | ±100 nm |

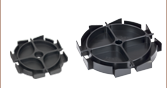

| Mounting Base | |

Click to Enlarge

1x4 Wideband Single Mode Coupler Mounted on FCQB Base (Available Below)

Features

- Split Input Signal Evenly Into Four Output Ports

- Multiple Wavelength/Bandwidth Combinations Available (See Table to the Right for Options)

- 2.0 mm Narrow Key FC/PC or FC/APC Connectors

- Both Narrowband and Wideband Single Mode Couplers Include Test Reports

- Mount to an Optical Table with the FCQB Mounting Base (Available Below)

- Contact Us for Custom Wavelength, Coupling Ratio, and Connector Options

Thorlabs' Single Mode 1x4 Fiber Optic Couplers allow a user to split a single input signal evenly into four output signals. Several center wavelength options are available (see the table to the right for details). Narrowband couplers have a ±15 nm bandwidth, dual-window couplers have a ±40 nm bandwidth around each center wavelength, and wideband couplers have a ±50 nm or ±100 nm bandwidth. 1x4 couplers are manufactured using three 50:50 fiber couplers to split the signal from the input port (see the 1x4 Coupler Tutorial for details); they cannot be used in reverse to combine light from four sources. The unused ports on these internal 50:50 fiber couplers are terminated in a manner that minimizes back reflections.

For our wideband 1x4 couplers, Thorlabs provides an individual test data sheet with each coupler that includes coupling data and performance graphs. These graphs, which show data within the design bandwidth and also show measured data outside of the specified bandwidth including the entire wavelength range where the coupling ratio meets the specified tolerance. Sample data sheets for our 1x4 wideband couplers can be viewed below. Please note that the data sheets for the 630 nm and 1064 nm 1x4 narrowband couplers do not include performance graphs, but a typical performance plot is included in the spec sheets below. Our couplers have undergone extensive testing to ensure they meet or surpass Telcordia requirements; please see the Reliability Testing tab for details.

Each single mode coupler is contained in a compact 100 mm x 80 mm x 10 mm housing that includes four through holes for mounting the device to our FCQB mounting base (available separately below). Narrowband and wideband couplers use a labeled red housing and 0.8 m fiber leads jacketed using Ø900 µm Hytrel® tubing. Dual-window couplers feature either a labeled red housing and 0.8 m fiber leads jacketed using Ø900 µm Hytrel® tubing, or a labeled black housing and 0.8 m fiber leads jacketed using Ø3 mm yellow furcation tubing. Couplers are offered from stock with 2.0 mm narrow key FC/PC or FC/APC connectors. Custom coupler configurations with other wavelengths, fiber types, coupling ratios, connectors, or port configurations are also available. Please contact Tech Support with inquiries.

Thorlabs also offers 405 nm single mode 1x4 fiber optic couplers that are not sold from stock. Please visit our 405 nm single mode couplers page for more details.

| Alternative Fiber Coupler & Splitter Options | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Double-Clad Couplers | Single Mode Couplers | Single Mode PLC Splitters | Multimode Couplers | Polarization-Maintaining Couplers | Wavelength Division Multiplexers (WDM) |

||||||

| 2x2 | 1x2 | 2x2 | 1x4 | 1x8 | 1x16 | 1x2 | 2x2 | 1x2 | 2x2 | 1x4 | |

Definition of 1x4 Fused Fiber Optic Coupler Specifications

This tab provides a brief explanation of how we determine several key specifications for our 1x4 couplers. 1x4 couplers are manufactured using three 50:50 couplers internally to split the input signal evenly among four outputs (as shown in the schematic below). Any unused ports are terminated using a propietary method that reduces back reflections. 1x4 couplers are not recommended for light combining applications and should only be used to split light. For combining light of different wavelengths, Thorlabs offers a line of wavelength division multiplexers (WDMs). The ports on our 1x4 couplers are configured as shown in the schematic below.

Excess Loss

Excess loss in dB is determined by the ratio of the total input power to the total output power:

Pinput is the input power and Pport1+Pport2+Pport3+Pport4 is the total output power. All powers are expressed in mW.

Optical Return Loss (ORL) / Directivity

The directivity refers to the fraction of input light that is lost in the internally terminated fiber ends within the coupler housing. It can be calculated in units of dB using the following equation:

where Pt1, Pt2, and Pt3 are the optical powers (in mW) in the internally terminated fiber ends shown in the image above. This is the result of back reflections at each coupler junction and represents a loss in the total light output at the output ports. For a 1x4 coupler with an even split, the directivity is equal to the optical return loss (ORL).

Insertion Loss

The insertion loss is defined as the ratio of the input power to the output power at one of the output legs of the coupler. Insertion loss is always specified in decibels (dB). It is generally defined using the equation below:

where Pin and Pout are the input and output powers (in mW). For our 1x4 couplers, the insertion loss specification is provided for each output port. To define the insertion loss for a specific output (e.g., port 1 or port 2), the equation is rewritten as:

Insertion loss inherently includes both coupling (e.g., light transferred to the other output legs) and excess loss (e.g., light lost from the coupler) effects. The maximum allowed insertion loss for each output is specified. Because the insertion loss in each output is correlated to light coupled to the other outputs, no coupler will ever have the maximum insertion loss in all outputs simultaneously.

Calculating Insertion Loss using Power Expressed in dBm

Insertion loss can also be easily calculated with the power expressed in units of dBm. The equation below shows the relationship between power expressed in mW and dBm:

Then, the insertion loss in dB can be calculated as follows:

Coupling Ratio

Insertion loss (in dB) is the ratio of the input power to the output power from each leg of the coupler as a function of wavelength. It captures both the coupling ratio and the excess loss. The coupling ratio is calculated from the measured insertion loss. Coupling ratio (in %) is the ratio of the optical power from each output port to the sum of the total power of all output ports as a function of wavelength. It is not impacted by spectral features such as the water absorption region because all output legs are affected equally.

Uniformity

The uniformity is also calculated from the measured insertion loss. Uniformity is the variation (in dB) of the insertion loss over the bandwidth as a function of wavelength. It is a measure of how evenly the insertion loss is distributed over the spectral range. The uniformity is defined as the difference between the insertion loss in one output leg at a given wavelength and the highest or lowest value of insertion loss over the specified wavelength range in that same output leg.

| Requirement Limits | |

|---|---|

| Parameter | Limit |

| Change in Insertion Loss (ΔIL) | ≤0.2 dB |

| Coupling Ratio | ±1.5% |

GR-1221-CORE Testing

Our 2x2 1300 nm Single Mode Fused Fiber Optic Couplers have undergone a reliability testing program inspired by GR-1221-CORE (Generic Reliability Assurance Requirements for Passive Optical Components, Issue 2). The selected test conditions are for uncontrolled environments and are some of the most stringent test conditions for passive components. The results of this testing program qualify these couplers and their manufacturing process for volume production and use in uncontrolled environments. To download a PDF of this test report, please click here.

Click To Enlarge

Click To EnlargeClose-Up of Mechanical Shock Test Setup

Click To Enlarge

Click To EnlargeSM-105 Mechanical Shock

Test Machine

Click To Enlarge

Vibration Test Setup

Click To Enlarge

Click To EnlargeDamp Heat Testing Setup

Testing Conditions

This test program consisted of five test groups with a sample size of 11 per group. Testing was conducted with a 1310 nm laser source input into 1310 tap couplers using a 1x16 waveguide coupler. The two outputs of every coupler were measured by a PM100USB power meter with an S154C sensor head.| Testing Conditions | ||

|---|---|---|

| Mechanical Testing (Group 1) | ||

| These fused couplers with a tap ratio of 10% underwent three mechanical tests; the mechanical shock and vibration tests were conducted by the NTS Environmental and Mechanical Testing Laboratory while the fiber side pull tests were performed in-house. In one test, the couplers were induced with mechanical shock using an Avex SM-105 mechanical shock test machine with a 3200B4 accelerometer. In another, they were induced with vibration using a Dynamic Solutions DS-2200VH/8-19 vibration system with a VT1436 vibration controller and a 356A01 accelerometer. The couplers also underwent a fiber side pull in two directions with a weight of 0.23 kg at 90° for 5 seconds. | ||

| Test Parameter | Conditions | Reference |

| Mechanical Shock | Acceleration: 500 g Pulse Width: 1 ms Pulse Shape: Half-Sine # of Directions: 6 # of Shocks/Direction: 5 |

MIL-STD-993 Method 2002 |

| Vibration | Acceleration: 20 g Frequency Range: 20 Hz to 2000 Hz Duration: 4 min/cycle Number of Cycles/Axis: 4 Axes: X, Y, Z |

MIL-STD-883 Method 2007 Condition A |

| Fiber Side Pull | 0.23 kg, 90°, 5 sec, 2 directions | GR-1209-CORE |

| Click for Graphs:

|

||

| Damp Heat Storage (Group 2) | ||

| The performance of these couplers was tested in damp heat at a Thorlabs facility. A Test Equity Model 115A Temperature Chamber was used to maintain an 85 °C ± 2 °C temperature with 85% ± 5% relative humidity for 2000 hours. | ||

| Test Parameter | Conditions | Reference |

| Damp Heat | 85 °C (±2 °C) 85% (±5%) Relative Humidity 2000 Hours |

MIL-STD-883 Method 103 |

| Click for Graphs:

|

||

| High Temperature Storage (Group 3) | ||

| The performance of these couplers was tested in dry high temperatures in a Thorlabs facility. A Test Equity Model 115A Temperature Chamber was used to maintain an 85 °C ± 2 °C temperature with <40% Relative Humidity for 2000 hours. | ||

| Test Parameter | Conditions | Reference |

| High Temperature Storage (Dry Heat) | 85 °C (±2 °C) <40% Relative Humidity 2000 Hours |

EIA/TIA-455-4A |

| Click for Graphs:

|

||

| Low Temperature Storage (Group 4) | ||

| The performance of these couplers was tested in low temperatures at a Thorlabs facility. A Test Equity Model 115A Temperature Chamber was used to maintain a -40 °C ± 5 °C temperature with uncontrolled relative humidity for 2000 hours. | ||

| Test Parameter | Conditions | Reference |

| Low Temperature Storage | -40 °C (±5 °C) Uncontrolled Relative Humidity 2000 Hours |

EIA/TIA-455-4A |

| Click for Graphs:

|

||

| Temperature Cycling (Group 5) | ||

| At a Thorlabs facility, the performance of these couplers was tested during temperature cycling of their environment. The temperature varied from -40 °C to 85 °C (±2 °C) through 400 cycles with a 10 minutes pause at room temperature at each cycle. | ||

| Test Parameter | Conditions | Reference |

| Temperature Cycling | -40 °C to 85 °C (±2 °C) 400 Cycles with 10 Minute Pause at Room Temperature |

MIL-STD-883 Method 1010 |

| Click for Graphs:

|

||

| Quick Links |

|---|

| Damage at the Air / Glass Interface |

| Intrinsic Damage Threshold |

| Preparation and Handling of Optical Fibers |

Laser-Induced Damage in Silica Optical Fibers

The following tutorial details damage mechanisms relevant to unterminated (bare) fiber, terminated optical fiber, and other fiber components from laser light sources. These mechanisms include damage that occurs at the air / glass interface (when free-space coupling or when using connectors) and in the optical fiber itself. A fiber component, such as a bare fiber, patch cable, or fused coupler, may have multiple potential avenues for damage (e.g., connectors, fiber end faces, and the device itself). The maximum power that a fiber can handle will always be limited by the lowest limit of any of these damage mechanisms.

While the damage threshold can be estimated using scaling relations and general rules, absolute damage thresholds in optical fibers are very application dependent and user specific. Users can use this guide to estimate a safe power level that minimizes the risk of damage. Following all appropriate preparation and handling guidelines, users should be able to operate a fiber component up to the specified maximum power level; if no maximum is specified for a component, users should abide by the "practical safe level" described below for safe operation of the component. Factors that can reduce power handling and cause damage to a fiber component include, but are not limited to, misalignment during fiber coupling, contamination of the fiber end face, or imperfections in the fiber itself. For further discussion about an optical fiber’s power handling abilities for a specific application, please contact Thorlabs’ Tech Support.

Click to Enlarge

Undamaged Fiber End

Click to Enlarge

Damaged Fiber End

Damage at the Air / Glass Interface

There are several potential damage mechanisms that can occur at the air / glass interface. Light is incident on this interface when free-space coupling or when two fibers are mated using optical connectors. High-intensity light can damage the end face leading to reduced power handling and permanent damage to the fiber. For fibers terminated with optical connectors where the connectors are fixed to the fiber ends using epoxy, the heat generated by high-intensity light can burn the epoxy and leave residues on the fiber facet directly in the beam path.

| Estimated Optical Power Densities on Air / Glass Interfacea | ||

|---|---|---|

| Type | Theoretical Damage Thresholdb | Practical Safe Levelc |

| CW (Average Power) |

~1 MW/cm2 | ~250 kW/cm2 |

| 10 ns Pulsed (Peak Power) |

~5 GW/cm2 | ~1 GW/cm2 |

Damage Mechanisms on the Bare Fiber End Face

Damage mechanisms on a fiber end face can be modeled similarly to bulk optics, and industry-standard damage thresholds for UV Fused Silica substrates can be applied to silica-based fiber. However, unlike bulk optics, the relevant surface areas and beam diameters involved at the air / glass interface of an optical fiber are very small, particularly for coupling into single mode (SM) fiber. therefore, for a given power density, the power incident on the fiber needs to be lower for a smaller beam diameter.

The table to the right lists two thresholds for optical power densities: a theoretical damage threshold and a "practical safe level". In general, the theoretical damage threshold represents the estimated maximum power density that can be incident on the fiber end face without risking damage with very good fiber end face and coupling conditions. The "practical safe level" power density represents minimal risk of fiber damage. Operating a fiber or component beyond the practical safe level is possible, but users must follow the appropriate handling instructions and verify performance at low powers prior to use.

Calculating the Effective Area for Single Mode and Multimode Fibers

The effective area for single mode (SM) fiber is defined by the mode field diameter (MFD), which is the cross-sectional area through which light propagates in the fiber; this area includes the fiber core and also a portion of the cladding. To achieve good efficiency when coupling into a single mode fiber, the diameter of the input beam must match the MFD of the fiber.

As an example, SM400 single mode fiber has a mode field diameter (MFD) of ~Ø3 µm operating at 400 nm, while the MFD for SMF-28 Ultra single mode fiber operating at 1550 nm is Ø10.5 µm. The effective area for these fibers can be calculated as follows:

SM400 Fiber: Area = Pi x (MFD/2)2 = Pi x (1.5 µm)2 = 7.07 µm2 = 7.07 x 10-8 cm2

SMF-28 Ultra Fiber: Area = Pi x (MFD/2)2 = Pi x (5.25 µm)2 = 86.6 µm2 = 8.66 x 10-7 cm2

To estimate the power level that a fiber facet can handle, the power density is multiplied by the effective area. Please note that this calculation assumes a uniform intensity profile, but most laser beams exhibit a Gaussian-like shape within single mode fiber, resulting in a higher power density at the center of the beam compared to the edges. Therefore, these calculations will slightly overestimate the power corresponding to the damage threshold or the practical safe level. Using the estimated power densities assuming a CW light source, we can determine the corresponding power levels as:

SM400 Fiber: 7.07 x 10-8 cm2 x 1 MW/cm2 = 7.1 x 10-8 MW = 71 mW (Theoretical Damage Threshold)

7.07 x 10-8 cm2 x 250 kW/cm2 = 1.8 x 10-5 kW = 18 mW (Practical Safe Level)

SMF-28 Ultra Fiber: 8.66 x 10-7 cm2 x 1 MW/cm2 = 8.7 x 10-7 MW = 870 mW (Theoretical Damage Threshold)

8.66 x 10-7 cm2 x 250 kW/cm2 = 2.1 x 10-4 kW = 210 mW (Practical Safe Level)

The effective area of a multimode (MM) fiber is defined by the core diameter, which is typically far larger than the MFD of an SM fiber. For optimal coupling, Thorlabs recommends focusing a beam to a spot roughly 70 - 80% of the core diameter. The larger effective area of MM fibers lowers the power density on the fiber end face, allowing higher optical powers (typically on the order of kilowatts) to be coupled into multimode fiber without damage.

Damage Mechanisms Related to Ferrule / Connector Termination

Click to Enlarge

Plot showing approximate input power that can be incident on a single mode silica optical fiber with a termination. Each line shows the estimated power level due to a specific damage mechanism. The maximum power handling is limited by the lowest power level from all relevant damage mechanisms (indicated by a solid line).

Fibers terminated with optical connectors have additional power handling considerations. Fiber is typically terminated using epoxy to bond the fiber to a ceramic or steel ferrule. When light is coupled into the fiber through a connector, light that does not enter the core and propagate down the fiber is scattered into the outer layers of the fiber, into the ferrule, and the epoxy used to hold the fiber in the ferrule. If the light is intense enough, it can burn the epoxy, causing it to vaporize and deposit a residue on the face of the connector. This results in localized absorption sites on the fiber end face that reduce coupling efficiency and increase scattering, causing further damage.

For several reasons, epoxy-related damage is dependent on the wavelength. In general, light scatters more strongly at short wavelengths than at longer wavelengths. Misalignment when coupling is also more likely due to the small MFD of short-wavelength SM fiber that also produces more scattered light.

To minimize the risk of burning the epoxy, fiber connectors can be constructed to have an epoxy-free air gap between the optical fiber and ferrule near the fiber end face. Our high-power multimode fiber patch cables use connectors with this design feature.

Determining Power Handling with Multiple Damage Mechanisms

When fiber cables or components have multiple avenues for damage (e.g., fiber patch cables), the maximum power handling is always limited by the lowest damage threshold that is relevant to the fiber component. In general, this represents the highest input power that can be incident on the patch cable end face and not the coupled output power.

As an illustrative example, the graph to the right shows an estimate of the power handling limitations of a single mode fiber patch cable due to damage to the fiber end face and damage via an optical connector. The total input power handling of a terminated fiber at a given wavelength is limited by the lower of the two limitations at any given wavelength (indicated by the solid lines). A single mode fiber operating at around 488 nm is primarily limited by damage to the fiber end face (blue solid line), but fibers operating at 1550 nm are limited by damage to the optical connector (red solid line).

In the case of a multimode fiber, the effective mode area is defined by the core diameter, which is larger than the effective mode area for SM fiber. This results in a lower power density on the fiber end face and allows higher optical powers (on the order of kilowatts) to be coupled into the fiber without damage (not shown in graph). However, the damage limit of the ferrule / connector termination remains unchanged and as a result, the maximum power handling for a multimode fiber is limited by the ferrule and connector termination.

Please note that these are rough estimates of power levels where damage is very unlikely with proper handling and alignment procedures. It is worth noting that optical fibers are frequently used at power levels above those described here. However, these applications typically require expert users and testing at lower powers first to minimize risk of damage. Even still, optical fiber components should be considered a consumable lab supply if used at high power levels.

Intrinsic Damage Threshold

In addition to damage mechanisms at the air / glass interface, optical fibers also display power handling limitations due to damage mechanisms within the optical fiber itself. These limitations will affect all fiber components as they are intrinsic to the fiber itself. Two categories of damage within the fiber are damage from bend losses and damage from photodarkening.

Bend Losses

Bend losses occur when a fiber is bent to a point where light traveling in the core is incident on the core/cladding interface at an angle higher than the critical angle, making total internal reflection impossible. Under these circumstances, light escapes the fiber, often in a localized area. The light escaping the fiber typically has a high power density, which burns the fiber coating as well as any surrounding furcation tubing.

A special category of optical fiber, called double-clad fiber, can reduce the risk of bend-loss damage by allowing the fiber’s cladding (2nd layer) to also function as a waveguide in addition to the core. By making the critical angle of the cladding/coating interface higher than the critical angle of the core/clad interface, light that escapes the core is loosely confined within the cladding. It will then leak out over a distance of centimeters or meters instead of at one localized spot within the fiber, minimizing the risk of damage. Thorlabs manufactures and sells 0.22 NA double-clad multimode fiber, which boasts very high, megawatt range power handling.

Photodarkening

A second damage mechanism, called photodarkening or solarization, can occur in fibers used with ultraviolet or short-wavelength visible light, particularly those with germanium-doped cores. Fibers used at these wavelengths will experience increased attenuation over time. The mechanism that causes photodarkening is largely unknown, but several fiber designs have been developed to mitigate it. For example, fibers with a very low hydroxyl ion (OH) content have been found to resist photodarkening and using other dopants, such as fluorine, can also reduce photodarkening.

Even with the above strategies in place, all fibers eventually experience photodarkening when used with UV or short-wavelength light, and thus, fibers used at these wavelengths should be considered consumables.

Preparation and Handling of Optical Fibers

General Cleaning and Operation Guidelines

These general cleaning and operation guidelines are recommended for all fiber optic products. Users should still follow specific guidelines for an individual product as outlined in the support documentation or manual. Damage threshold calculations only apply when all appropriate cleaning and handling procedures are followed.

-

All light sources should be turned off prior to installing or integrating optical fibers (terminated or bare). This ensures that focused beams of light are not incident on fragile parts of the connector or fiber, which can possibly cause damage.

-

The power-handling capability of an optical fiber is directly linked to the quality of the fiber/connector end face. Always inspect the fiber end prior to connecting the fiber to an optical system. The fiber end face should be clean and clear of dirt and other contaminants that can cause scattering of coupled light. Bare fiber should be cleaved prior to use and users should inspect the fiber end to ensure a good quality cleave is achieved.

-

If an optical fiber is to be spliced into the optical system, users should first verify that the splice is of good quality at a low optical power prior to high-power use. Poor splice quality may increase light scattering at the splice interface, which can be a source of fiber damage.

-

Users should use low power when aligning the system and optimizing coupling; this minimizes exposure of other parts of the fiber (other than the core) to light. Damage from scattered light can occur if a high power beam is focused on the cladding, coating, or connector.

Tips for Using Fiber at Higher Optical Power

Optical fibers and fiber components should generally be operated within safe power level limits, but under ideal conditions (very good optical alignment and very clean optical end faces), the power handling of a fiber component may be increased. Users must verify the performance and stability of a fiber component within their system prior to increasing input or output power and follow all necessary safety and operation instructions. The tips below are useful suggestions when considering increasing optical power in an optical fiber or component.

-

Splicing a fiber component into a system using a fiber splicer can increase power handling as it minimizes possibility of air/fiber interface damage. Users should follow all appropriate guidelines to prepare and make a high-quality fiber splice. Poor splices can lead to scattering or regions of highly localized heat at the splice interface that can damage the fiber.

-

After connecting the fiber or component, the system should be tested and aligned using a light source at low power. The system power can be ramped up slowly to the desired output power while periodically verifying all components are properly aligned and that coupling efficiency is not changing with respect to optical launch power.

-

Bend losses that result from sharply bending a fiber can cause light to leak from the fiber in the stressed area. When operating at high power, the localized heating that can occur when a large amount of light escapes a small localized area (the stressed region) can damage the fiber. Avoid disturbing or accidently bending fibers during operation to minimize bend losses.

-

Users should always choose the appropriate optical fiber for a given application. For example, large-mode-area fibers are a good alternative to standard single mode fibers in high-power applications as they provide good beam quality with a larger MFD, decreasing the power density on the air/fiber interface.

-

Step-index silica single mode fibers are normally not used for ultraviolet light or high-peak-power pulsed applications due to the high spatial power densities associated with these applications.

| Posted Comments: | |

Mario Stipcevic

(posted 2020-04-18 21:42:06.93) Hello!

I wonder of tehse 1 to 4 controllers can be used to combine 4 sources into one, that is in the oposite directon? If not, do you have such a product?

Are the fibers SM or MM?

Thanks YLohia

(posted 2020-04-20 08:44:41.0) Hello, thank you for contacting Thorlabs. 1x4 couplers are manufactured using three 50:50 couplers internally to split the input signal evenly among four outputs. 1x4 couplers are not recommended for light combining applications and should only be used to split light. For combining light of different wavelengths, we offer a line of wavelength division multiplexers (WDMs): https://www.thorlabs.com/navigation.cfm?guide_id=2238. These fibers are SM. jean-baptiste.lebouquin

(posted 2017-10-03 15:29:42.763) Is it possible to have a specification on the length match between the routing ports ? Ideally, we need the 4 outputs to be at the same fibre propagation (+-1mm) from the input port. Thanks. nbayconich

(posted 2017-10-10 01:25:37.0) Thank you for contacting Thorlabs. These couplers have a +7.5cm -0.0cm length tolerance on the output connectors. For near identical propagation lengths we can look into providing a custom option. I will reach out to you directly with more information. fernando.stefani

(posted 2016-12-15 12:46:22.26) Dear Thorlabs team,

I would like to have a 1x4 single mode fiber coupler with different fiber length on each output. Could you make such a custom coupler for us?

The application is to generate 4 separate laser pulses delayed about 6.25 ns from each other, from one laser working at 40 MHz repetition rate. tfrisch

(posted 2016-12-19 04:15:27.0) Hello, thank you for contacting Thorlabs. While I have some concerns about the energy specifications of your laser, I would typically recommend that optical delays be done either in another fiber connected to the coupler, or in freespace where you can change the optical path length more easily. I would not recommend a custom because the fiber lengths would be critical, and if one leg was damaged, the would device would then be off spec. I will reach out to you with more details. pwilliams

(posted 2016-09-07 09:09:56.193) Hello,

I'm looking for a 1x16 (or more...preferably 1x24) single mode fiber optic coupler for 532nm. Can Thorlabs make custom couplers or can someone point me towards a company that makes couplers like this?

Thank you for your help,

Patrick Williams

Electrical Test Engineer

Applied Physical Electronics, L.C. tfrisch

(posted 2016-09-07 03:51:27.0) Hello, thank you for contacting Thorlabs. I will reach out to you directly about our capabilities. jlow

(posted 2013-01-17 17:46:00.0) Response from Jeremy at Thorlabs: We will get in touch with you to discuss about your application. igkiou

(posted 2013-01-09 20:49:28.89) Hi, I use your RGB1-FC RGB combiner to multiplex three laser outputs into "white" light. I want then to use this white light to simultaneously drive 4 collimators. Given that FCQ632-FC is designed for 632nm and uses an SM600 fiber, I assume I cannot use it for this purpose. Do you offer some similar product I could use? tcohen

(posted 2012-07-05 15:43:00.0) Response from Tim at Thorlabs: Thank you for contacting us! These are bi-directional. However, please note that you will not get the full power from each of the four legs going to the main lead but it will instead be closer to the original coupling ratio for each leg. Also, please note that we don’t test these for bi-directional operation and so the coupling ratio may vary. alexander.nevsky

(posted 2012-07-04 19:15:24.0) Hello!

I have a technical question. Can this coupler be used in a reverse direction? To combine 4 radiations into one fiber?

Thanks!

A. Nevsky

Uni-Duesseldorf |

- Split 560 nm Signals at 25:25:25:25 Coupling Ratio

- ±50 nm Bandwidth

- Individual Test Report Included with Each Coupler; Click Here for a Sample Data Sheet

- Available with 2.0 mm Narrow Key FC/PC or FC/APC Connectors

These 1x4 Wideband Fiber Optic Couplers are designed for splitting a single input signal at 560 nm equally into four output signals. The couplers have an operating bandwidth of ±50 nm and are available with 2.0 mm narrow key FC/PC or FC/APC connectors. They have a max power level of 100 mW with connectors or bare fiber and 250 mW when spliced (see the Damage Threshold tab for more details).

| Item # | Infoa | Center Wavelength |

Bandwidth | Coupling Ratio (%)b (Click for Plot) |

Coupling Ratio Tolerance |

Insertion Lossb |

Excess Lossb |

Uniformityb | Fiber Typed | Termination |

|---|---|---|---|---|---|---|---|---|---|---|

| TWQ560HFc | 560 nm | ±50 nm | 25:25:25:25 | ±5.0% | ≤7.6 dB (Each Output Port) |

≤0.6 dB |

≤1.5 dB |

460HP | FC/PC | |

| TWQ560HAc | FC/APC |

- Split 630 nm Signals at 25:25:25:25 Coupling Ratio

- ±15 nm Bandwidth

- Individual Test Report Included with Each Coupler; Click Here for a Sample Data Sheet

- Available with 2.0 mm Narrow Key FC/PC or FC/APC Connectors

These 1x4 Narrowband Fiber Optic Couplers are designed to split a single input signal at 630 nm equally into four output signals. The couplers have an operating bandwidth of ±15 nm and are available with 2.0 mm narrow key FC/PC or FC/APC connectors. They can handle a max power of 300 mW with connectors or unterminated (bare) fiber and 0.5 W when spliced (see the Damage Threshold tab for more details).

| Item # | Infoa | Center Wavelength |

Bandwidth | Coupling Ratio (%)b (Click for Plot) |

Coupling Ratio Tolerance |

Insertion Lossb,c |

Excess Lossb,c |

Uniformity | Fiber Typed | Termination |

|---|---|---|---|---|---|---|---|---|---|---|

| TNQ630HF | 630 nm | ±15 nm | 25:25:25:25 | ±10.0% | ≤7.6 dB (Each Output Port) |

≤0.6 dB |

- | 630HP | FC/PC | |

| TNQ630HA | FC/APC |

- Split 850 nm Signals at 25:25:25:25 Coupling Ratio

- ±100 nm Bandwidth

- Individual Test Report Included with Each Coupler; Click Here for a Sample Data Sheet

- Available with 2.0 mm Narrow Key FC/PC or FC/APC Connectors

These 1x4 Wideband Fiber Optic Couplers are designed for splitting a single input signal at 850 nm equally into four output signals. The couplers have an operating bandwidth of ±100 nm and are available with 2.0 mm narrow key FC/PC or FC/APC connectors. They can handle a max power of 500 mW with connectors or unterminated (bare) fiber and 2 W when spliced (see the Damage Threshold tab for more details).

| Item # | Infoa | Center Wavelength |

Bandwidth | Coupling Ratio (%)b (Click for Plot) |

Coupling Ratio Tolerance |

Insertion Lossb |

Excess Lossb |

Uniformityb | Fiber Typed | Termination |

|---|---|---|---|---|---|---|---|---|---|---|

| TWQ850HFc | 850 nm | ±100 nm | 25:25:25:25 | ±6.0% | ≤7.8 dB (Each Output Port) |

≤0.6 dB |

≤2.0 dB |

780HP | FC/PC | |

| TWQ850HAc | FC/APC |

- Split 1064 nm Signals at 25:25:25:25 Coupling Ratio

- ±15 nm or ±100 nm Bandwidth

- Individual Test Report Included with Each Coupler; Click Here for a Sample Data Sheet

- Available with 2.0 mm Narrow Key FC/PC or FC/APC Connectors

These 1x4 Fiber Optic Couplers are designed for splitting a single input signal at 1064 nm equally into four output signals. The couplers feature an operating bandwidth of ±15 nm or ±100 nm and are available with 2.0 mm narrow key FC/PC or FC/APC connectors. These narrowband and wideband couplers can handle a max power of 1 W with connectors or bare fiber and 5 W when spliced (see the Damage Threshold tab for more details).

| Item # | Infoa | Center Wavelength |

Bandwidth | Coupling Ratio (%)b (Click for Plot) |

Coupling Ratio Tolerance |

Insertion Lossb |

Excess Lossb |

Uniformityb | Fiber Typec | Termination |

|---|---|---|---|---|---|---|---|---|---|---|

| TNQ1064AHFd | 1064 nm | ±15 nm | 25:25:25:25 | ±3.0% | ≤7.1 dB (Each Output Port) | ≤0.5 dB | - | HI1060 (0.14 NA) |

FC/PC | |

| TNQ1064AHAd | FC/APC | |||||||||

| TNQ1064BHFd | HI1060 FLEX (0.22 NA) |

FC/PC | ||||||||

| TNQ1064BHAd | FC/APC | |||||||||

| TWQ1064BHFd | 1064 nm | ±100 nm | 25:25:25:25 | ±3.5% | ≤7.1 dB (Each Output Port) | ≤0.4 dB | ≤1.0 dB | HI1060 FLEX (0.22 NA) |

FC/PC | |

| TWQ1064BHAd | FC/APC |

- Split 1300 nm Signals at 25:25:25:25 Coupling Ratio

- ±100 nm Bandwidth

- Individual Test Report Included with Each Coupler; Click Here for a Sample Data Sheet

- Available with 2.0 mm Narrow Key FC/PC or FC/APC Connectors

These 1x4 Wideband Fiber Optic Couplers are designed for splitting a single input signal at 1300 nm equally into four output signals. The couplers have an operating bandwidth of ±100 nm and are available with 2.0 mm narrow key FC/PC or FC/APC connectors. They can handle a max power of 1 W with connectors or bare fiber and 5 W when spliced (see the Damage Threshold tab for more details).

| Item # | Infoa | Center Wavelength |

Bandwidth | Coupling Ratio (%)b (Click for Plot) |

Coupling Ratio Tolerance |

Insertion Lossb |

Excess Lossb |

Uniformityb | Fiber Typec | Termination |

|---|---|---|---|---|---|---|---|---|---|---|

| TWQ1300HFd | 1300 nm | ±100 nm | 25:25:25:25 | ±3.0% | ≤6.9 dB (Each Output Port) |

≤0.3 dB |

≤0.5 dB |

SMF-28 | FC/PC | |

| TWQ1300HAd | FC/APC |

- Split 1310 nm or 1550 nm Signals at 25:25:25:25 Coupling Ratio

- ±40 nm Bandwidth Around Each Center Wavelength

- Individual Test Report Included with Each Coupler; Click Here for a Sample Data Sheet

- Available with 2.0 mm Narrow Key FC/PC or FC/APC Connectors

These 1x4 Dual-Window Fiber Optic Couplers are designed for splitting a single input signal at 1310 nm or 1550 nm equally into four output signals. The couplers have operating bandwidths of ±40 nm and are available with 2.0 mm narrow key FC/PC or FC/APC connectors. They can handle a max power of 1 W with connectors or bare fiber and 5 W when spliced (see the Damage Threshold tab for more details).

| Item # | Infoa | Center Wavelength |

Bandwidth | Coupling Ratio (%)b (Click for Plot) |

Coupling Ratio Tolerance |

Insertion Lossb |

Excess Lossb |

Uniformityb | Fiber Typec | Termination |

|---|---|---|---|---|---|---|---|---|---|---|

| TDQ1315HFd | 1310/1550 nm | ±40 nm | 25:25:25:25 | ±4.0% | ≤7.3 dB (Each Output Port) |

≤0.5 dB | - | SMF-28 | FC/PC | |

| TDQ1315HAd | FC/APC |

- Split 1550 nm Signals at 25:25:25:25 Coupling Ratio

- ±100 nm Bandwidth

- Individual Test Report Included with Each Coupler; Click Here for a Sample Data Sheet

- Available with 2.0 mm Narrow Key FC/PC or FC/APC Connectors

These 1x4 Wideband Fiber Optic Couplers are designed for splitting a single input signal at 1550 nm equally into four output signals. The couplers have an operating bandwidth of ±100 nm and are available with 2.0 mm narrow key FC/PC or FC/APC connectors. They can handle a max power of 1 W with connectors or bare fiber and 5 W when spliced (see the Damage Threshold tab for more details).

| Item # | Infoa | Center Wavelength |

Bandwidth | Coupling Ratio (%)b |

Coupling Ratio Tolerance |

Insertion Lossb |

Excess Lossb |

Uniformityb | Fiber Typed | Termination |

|---|---|---|---|---|---|---|---|---|---|---|

| TWQ1550HFc | 1550 nm | ±100 nm | 25:25:25:25 (Click for Plot) |

±3.0% | ≤6.9 dB (Each Output Port) |

≤0.3 dB |

≤0.5 dB |

SMF-28 | FC/PC | |

| TWQ1550HAc | FC/APC |

- Mounting Base for RGB Wavelength Combiners, 1x4 Single Mode (SM) Couplers, or 1x4 Polarization-Maintaining (PM) Couplers

- Four M2 Taps for Mounting Fiber Optic Component Housing

- 2.25" Long Clearance Slots Accepts 1/4"-20 (M6) Screws

- Four M2 Mounting Screws Included

Our FCQB mounting base provides two 2.25" long clearance slots for 1/4" (M6) cap screwsto secure the base to an optical table or other tapped surface. The two clearance slots are located 4" (101.6 mm) apart at opposite edges of the mounting base. Four M2 taps between the clearance slots are positioned to align with the through holes in Thorlabs' RGB wavelength combiners, 1x4 SM Couplers, or 1x4 PM Couplers. Four M2 screws are included.

Products Home

Products Home

Zoom

Zoom

SM 1x4 Fiber Couplers

SM 1x4 Fiber Couplers