1/4"-100 Matched Adjuster/Bushing Pairs and Accessories

- 1/4"-100 Matched Adjusters

- Adjuster/Bushing Pairs Based on POLARIS-K1 Mount Adjuster Design

- Thread Tolerances Exceed Class 3 Standards

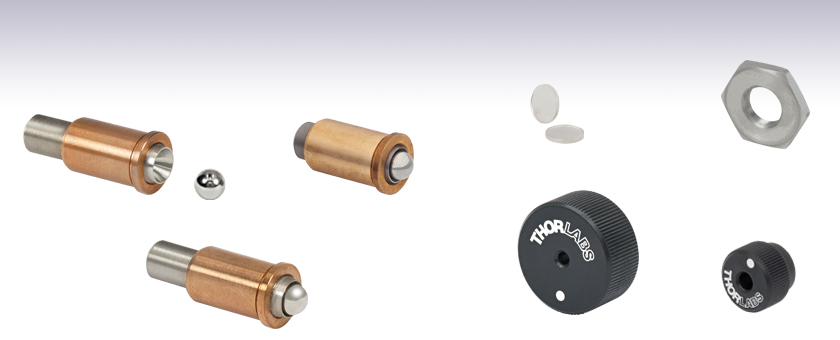

P25SB100L

Actuator/Bushing Pair with Loose Ball

P25SB100

High-Temperature Actuator/Bushing Pair

P25SB075V

Vacuum-Compatible Actuator/Bushing Pair

F25USK2

Large Removable Adjuster Knob

P25SK2

Sapphire

Contact Pads

POLARIS-LN1

Lock Nut

F25USK1

Small Removable Adjuster Knob

Please Wait

| Selection Guide for Adjustment Screws |

|---|

| Imperial |

| 6-80 |

| 3/16"-100 |

| 3/16"-120 |

| 1/4"- 80 |

| 1/4"-80 with Differential Adjuster |

| 1/4"-100 |

| 1/4"-100 Matched Adjuster/Bushing Pair |

| 1/4"-170 Matched Adjuster/Bushing Pair |

| 3/8"-100 |

| Metric |

| M2 x 0.20 |

| M2.5 × 0.20 |

| M3 × 0.20 |

| M3 × 0.25 |

| M4 x 0.25 |

| M6 × 0.25 |

Click to Enlarge

Back View of P25SB075V Actuator/Bushing Pair

Features

- Matched Actuators as Used in Our Ø1" POLARIS-K1 and POLARIS-K1-H Mirror Mounts

- Threads with Better than Class 3 Fit Prevent Alignment Drift

- Usable up to 200 °C and Vacuum Compatible down to 10-9 Torr

- 5/64" Hex on Adjuster Screw

- Phosphor Bronze Bushing with Stainless Steel Adjuster

- Adjuster Accessories Include Lock Nut, Locking Collar, Knobs, and Sapphire Contact Pads

The P25SB Series of Matched Adjuster/Bushing Pairs are those used in several of our Polaris® Mirror Mounts. The minimal lubrication and tight tolerances result in alignments that can be extremely stable, even after being adjusted. In addition, these adjusters have an extremely smooth feel that allows the user to make small repeatable adjustments. Test data of our Ø1" Polaris Mirror Mount shows how the P25SB100L results in accurate movements that do not change over time.

Click to Enlarge

Mechanical Drawing of Matched Actuator/Bushing Pairs

These matched 100 TPI adjusters and bushings are manufactured to tighter tolerances than the ASME/ANSI Class 3 UTS standard so that very little adjuster lubricant is needed. In typical adjusters, actuator adjustments cause the lubricant to be squeezed out of some spaces and built up in others. Over time this uneven lubricant distribution will relax slowly back into an equilibrium state, which may cause the adjuster screw to move. Thorlabs' matched adjusters do not suffer from these problems due to their tighter tolerances.

These adjusters may be actuated using a 5/64" hex key, screw-on knobs (sold below), or the HKTS-5/64 hex key knob (sold below). A lock nut and locking collar are available below for long-term stability.

Click to Enlarge

Figure 1

Assembly

The assembly process begins by producing a Ø0.350" +0.002"/-0.000" mating hole with Ø0.405 counterbore for the threaded bushing. Given the close fit between the threaded bushing and the mating adjuster screw, we caution against using a press fit to assemble these products. For our own production needs, we use a permanent anaerobic adhesive that provides excellent long-term performance.

We recommend using Loctite Anaerobic Adhesive product number 680 or equivalent. In order to ensure maximum strength between the bonded parts, we strongly urge the user to follow carefully the instructions provided by Loctite, which specify the amount of clearance between the threaded bushing and the mounting plate. The most common source of failure is not allowing for the proper clearance between the parts being bonded since this clearance provides for the proper volume of adhesive.

As shown in the diagram to the right, the flange on the mating bushing is designed to support the axial load of the screw and bushing assembly.

When assembling, apply a small amount of the Loctite adhesive to both threaded bushings and the mounting plate and ensure a uniform distribution of the adhesive around the perimeter of the parts before assembly. After insertion, remove any excess adhesive from around the part.

Usage

We strongly recommend against disassembling Polaris matched pair adjusters/bushings. If taken apart, contaminants can adhere to the threads, which will affect the performance of the adjuster. Additionally, the adjusters and bushings are matched, and machined to extremely tight tolerances. If adjusters and bushings that do not match are threaded together, they will not perform correctly.

OEM & Custom Precision Screws

Thorlabs manufactures custom and high volume OEM precision screws and bushings with various diameters, lengths, and threads. To inquire about custom or OEM precision screws, please contact Technical Support or use the "Contact Us" form to the right. A specialist will contact you within 24 hours or the next business day.

Precision Screw Capabilities

Thorlabs' in-house machine shop, located in Newton, NJ, gives us the ability to quickly produce large quantities of precision screws and bushings. We are equipped to manufacture screw diameters ranging from 2 mm to 20 mm with lengths up to 165 mm and a maximum thread pitch of 200 TPI. Our standard adjuster screw design has a hardened steel ball tip to provide a single point of contact; for other applications we are able to provide adjusters without the steel ball. Custom orders can be achieved on a case-by-case basis. For large orders of an item, Thorlabs passes on to the customer the cost savings associated with planned production of high volumes of that item. For more information on Thorlabs' discount pricing policy, click the "V" link to the right. We also offer a large variety of stock precision screws, which are available here.

Fast Turn-Around Times

Our experienced, highly skilled machinists are running our on-site Citizen Swiss Screw Machines 24 hours a day, allowing us to produce high-volume custom and OEM orders. Each machine is capable of running unattended, producing one screw every 30 to 120 seconds. This flexibility allows us to fulfill multiple orders at once without sacrificing quality.

High Quality

Thorlabs inspects all of our fabricated precision screws and bushings after the initial fabrication process and right before packaging. All inspections adhere to the ANSI AQL1.5 acceptable quality level, which states that if a certain percentage, based upon the amount of product in a certain lot, does not meet specification, then the entire lot is not sold. This ensures that all customers receive the highest quality product every time and that all items will be of equal performance.

Precision Screw Production

| Posted Comments: | |

user

(posted 2020-12-28 22:46:10.307) What is the axial load capacity for the P25SB100 paired with the sapphire pads? llamb

(posted 2021-01-07 02:53:54.0) Thank you for contacting Thorlabs. While we do not have an explicit axial load capacity spec for these matched 1/4"-100 adjuster/bushing pairs, the recommended max axial load capacity should be comparable to that of our standard 1/4"-100 adjusters at 15 lbs (6.8 kg). We recommend that the load be as light as possible to keep the friction of the kinematic contact to the sapphire pad to a minimum. Jeff Behary

(posted 2020-08-11 17:45:56.843) Absolutely incredible. Beautful product and price! YLohia

(posted 2020-08-12 09:28:10.0) Hello Jeff, thank you for your feedback! We are always happy to hear our customers' thoughts on our products. Scott Selwinn

(posted 2019-10-17 14:45:16.13) What kind of grease do i put on these screws? Do you sell it. I will clean these parts which will remove the grease so I need to reapply it. Also are the screws/balls magnetic? YLohia

(posted 2019-10-21 12:24:42.0) Hello, thank you for contacting Thorlabs. We tried reaching out to you directly to gather more information on which screw you were specifically interested in, but it looks like the contact information provided was incorrect. If you still have questions regarding this, please email us at techsupport@thorlabs.com and we would be happy to help. sprieskins

(posted 2017-11-06 10:23:10.137) It will be nice to suggest/recommend glue as well if we are selling this pads. tfrisch

(posted 2017-12-14 08:49:41.0) Hello, thank you for contacting Thorlabs. We often use 353NDPK to attach these pads. |

| Specifications | |

|---|---|

| Thread Pitch | 100 TPI (Threads per Inch) |

| Mounting Hole Size | Ø0.350" +0.002"/-0.000" Ø0.405" Counterbore |

| Adjuster | 5/64" Hex |

| Materials | Bushing: Phosphor Bronze Adjuster: Stainless Steel |

- Matched Actuators as Used in Our POLARIS-K1 and POLARIS-K1-H Ø1" Mirror Mounts

- Threads with Better than Class 3 Fit Prevent Alignment Drift

- 0.75" or 1" Long with 100 Threads per Inch (TPI)

- Usable up to 200 °C and Vacuum Compatible down to 10-9 Torr

- Adjust Using a 5/64" Hex Key or HKTS-5/64 Hex Adjuster Knob (Available Below)

- Phosphor Bronze Bushing with Stainless Steel Adjuster

These matched actuator/bushing pairs are tightly toleranced for smooth adjustment and long-term stability. The bushing should be mounted in a bore with a diameter of 0.350" +0.002"/-0.000".

The P25SB100L includes an unmounted ball bearing, providing the option to freely mount the ball or to secure it with epoxy to the tip of the screw. All other matched adjuster/bushing pairs are sold with the ball mounted using our 353NDPK High-Temperature Epoxy, which enables constant performance up to 200 °C and can be used in a vacuum environment down to 10-9 Torr. The P25SB075V and P25SB100V are also assembled in a clean environment and double vacuum bagged to eliminate contamination when transported into a cleanroom, making them the ideal choice for vacuum applications.

- Compact Locking Collar: Ø0.33" (Ø8.4 mm), 0.08" (1.9 mm) Thick

- Use One Collar To Lock an Adjuster to a Bushing

- Use Two Collars to Create a Hard Stop on an Adjuster

- Install and Remove with the POLARIS-T2 Spanner Wrench

The POLARIS-LNS1 locking collar is a compact alternative to the lock nut sold above. This locking collar is compatible with all of the 1/4"-100 adjusters sold on this page, as well as those used in many of our mirror mounts and stages. This locking collar is compatible with Polaris mounts that have 1/4"-100 adjusters, excluding the piezo-driven mounts and mounts with low-profile adjusters (Item #s POLARIS-K1-H and POLARIS-K1-2AH). Each collar is only 0.08" (1.9 mm) thick and constructed of stainless steel. We recommend the POLARIS-T2 Spanner Wrench to install or remove these locking collars. A center through hole allows a 2 mm ball driver to pass through the spanner wrench, so that the adjuster can be held in position while the locking collar is engaged.

The locking collar can be used to lock an adjuster in a desired position or to create a hard stop at any position to prevent overdriving an adjuster. For applications that require frequent tuning of the adjusters, the locking collar only needs to be lightly tightened to a torque of approximately 4 to 8 oz-in (0.03 to 0.06 N·m). For long term stability, we recommend tightening to a torque of 32 oz-in, which can be achieved by using our TW13 preset torque wrench in combination with the POLARIS-T2 wrench. To avoid cross threading the locking collar, place it against the adjuster and "unscrew" the collar until you feel a slight drop; then thread the collar onto the adjuster.

Cleanroom and Vacuum Compatibility

This locking collar is compatible with cleanroom and vacuum applications. The locking collar is chemically cleaned using the Carpenter AAA passivation method to remove sulfur, iron, and contaminants from the surface. After passivation, it is double vacuum bagged to eliminate contamination when transported into a cleanroom.

| P25SK2 Specifications | |

|---|---|

| Diameter | 0.160" ± 0.001" |

| Thickness | 0.020" ± 0.001" |

| Flatness | 5 Fringes/Inch |

| Surface Polish | 80-50 Scratch-Dig |

| Parallelism | 3.5 arcmin |

| Hardness | 9 Mohs 1800 Knoop Parallel to C-Axis 2200 Knoop Perpendicular to C-Axis |

| Coefficient of Friction | 0.15 Against Steel |

Sapphire Contact Pads

P25SK2 Sapphire Contact Pads are used in our Polaris Mirror Mounts because they improve the adjustment precision and durability of the mount. They are highly durable, scratch resistant, and ideal for thermally demanding applications. Sapphire is the material of choice for very demanding applications that require reliability and strength at both high and low operating temperatures. A sapphire-to-steel interface has a very low coefficient of friction, which allows for very smooth movement. With exceptional surface hardness, sapphire can be scratched by only a few substances other than itself. It is chemically inert and insoluble to water, common acids, or alkalis for temperatures up to ~1000 °C.

- For Convenient Adjustment of 5/64" and 2 mm Hex-Driven Actuators

- Red Anodized Adjustment Knob with Engraved Hex Size

- Replaceable Hex Tip

- Sold in Packages of 4

These 5/64" Hex Key Adjuster Thumbscrews allow for quick adjustment of many 5/64" and 2 mm hex-driven actuators (or standard actuators with the knobs removed). These temporary knobs can be left in the screw's hex socket between adjustments for convenience (see photo to the right). An 8-32 setscrew (5/64" hex) secures the replaceable hex bit, which can be reversed if the tip is stripped. Contact Tech Support to order replacement hex key bits.

We offer hex key thumbscrews in sizes from 0.050" to 3/16" and 2 mm to 5 mm.

Click to Enlarge

F25USK1 and F25USK2 Knobs Shown Attached to a POLARIS-K1 Mirror Mount

| Item # | Knob Diameter |

|---|---|

| F25USK1 | 0.58" |

| F25USK2 | 0.925" |

- Use with 1/4"-100 Hex Adjusters

- Clearance Hole Allows Access to Hex Socket

- Knurled Knob Increases Adjustment Sensitivity

- Available in 2 Sizes (See Table to the Right)

These removable adjustment knobs are compatible with our 1/4"-100 adjusters, including those used in the Ø1" Polaris Kinematic Mounts. These knobs enable quick and easy tweaking of an actuator without needing a hex key.

We offer two sizes of adjustment knobs. The Ø0.58" standard size (F25USK1) is similar in size to the stainless steel knobs included with our Polaris mount, while the larger Ø0.925" size (F25USK2) provides additional angular resolution.

Please note that these knobs are not compatible with Polaris mounts that use side-hole adjusters. The recessed bore of knob is not deep enough to allow the knob to engage the threads on the side-hole adjuster.

Products Home

Products Home

Zoom

Zoom

Polaris® 1/4"-100 Matched Adjuster/Bushing Pairs

Polaris® 1/4"-100 Matched Adjuster/Bushing Pairs