High-Vacuum CF Flange Viewports for Ø1" Windows

- CF Flange Viewports for High-Vacuum Systems

- Compatible with Ø1" Flat Windows

- Sapphire, CaF2, or UV Fused Silica Windows

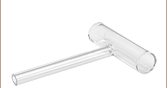

VPCH12-FL

Ø1" Flat Window

Viewport

Front

VGA10

Annealed Copper Gaskets,

10 Pack

Back

VMH6

Flange Mounting Hardware Pack

(6 Bolts, 6 Nuts, & 12 Washers)

Please Wait

| Common Vacuum Specifications | |

|---|---|

| Vacuum Level | 1 x 10-8 Torr (Max) |

| Max Temperature | 150 °C |

| Thermal Gradient | 20 °C/min (Max) |

Features

- Vacuum Level: 1 x 10-8 Torr (Max)

- Bake Temperature: 150 °C (Max)

- Flange Mounting Hardware Pack and Copper Gaskets Sold Below

Thorlabs' high-vacuum-compatible Ø2.75" (DN40) CF Flange Viewports for Ø1" Optics are offered with one of three uncoated window substrates: sapphire (150 nm - 4.5 µm), CaF2 (180 nm - 8.0 µm), or UVFS (185 nm - 2.1 µm). Please see the Graphs tab for transmission data. Additionally these viewports are compatible with our selection of stock Ø1" windows with thicknesses between 4.9 - 5.15 mm. These flanges are not compatible with wedged windows.

Designed for use at high-vacuum (HV) pressures, Thorlabs' CF viewports utilize Viton O-Ring seals to create an air-tight metal/glass seal, allowing for pressures down to 10-8 Torr. The vacuum windows are interchangeable, enabling the user to swap out vacuum windows mounted in our HV CF flanges. Additionally, CF flanges (viewports without vacuum windows) are also available that are also compatible with our Ø1" windows. Before swapping and attempting to install additional windows, please review the procedure outlined in the Window Installation tab above.

Copper gasket and mounting hardware sets for Ø2.75" CF flanges are also available below. Thorlabs also offers HV CF Flange Viewports for Ø1.5" windows and Ø1.5" wedged windows.

| Item # | VPCH312 | VPCH512 | VPCH412 |

|---|---|---|---|

| Window Material | Sapphire | CaF2 | UV Fused Silica |

| Window Item # | WG31050 | WG51050 | WG41050 |

| Window Diameter (Unmounted) | 1" | ||

| Clear Aperture (in Viewport) | Ø0.7125" (18 mm) | ||

| Transmitted Wavefront Error (@633 nm) | λ | λ/8 | λ/10 |

| Surface Quality | 60-40 Scratch-Dig | 20-10 Scratch-Dig | |

| Parallelism | <3 arcmin | <10 arcsec | ≤5 arcsec |

The graphs below show the transmission of light through uncoated sapphire, calcium fluoride (CaF2), and UV fused silica substrates. Raw data in the Excel format is available by clicking on the links below the graphs.

Our high-vacuum (HV) viewports offer superb flexibility by allowing the user to install or swap out windows as they desire, or as experimental conditions demand. Installation of the windows is relatively quick and simple. This guide explains how to install and change windows in our Ø1.5" HV viewports. The installation procedures for the Ø1" HV viewports are identical to those for the Ø1.5" HV viewports with the only difference being that the front face plate of the Ø1" viewport contains 4 screws instead of 6.

Step 1:

Left: Viewport with front face removed. Middle: O-Ring is removed, inspect the seat. Right: Using comprssed air, remove loose debris from the seat.

Inspect the o-ring and seat for pits, scratches, or contamination. Remove any loose debris from the seat using compressed air.

Step 2:

Install the o-ring in the seat, and place the window on top of the o-ring (left image). Place the face plate on top of the window (right image).

Step 3:

Place the screws in the face plate holes and use the 2 mm hex key to turn each screw ~1.5 turns so that they are flush with the face plate but not tight.

Step 4:

Use a torque driver set to 30 in-oz to screw in all six setscrews. Refer to the sequence shown in the pattern above for the correct order in which the screws should be torqued. Please note that over-torquing the screws will risk damaging the window. While the viewports for Ø1" windows only have 4 screws, use the same sequence for tightening the screws.

| Posted Comments: | |

Armindo Oliveira

(posted 2019-10-22 10:32:24.2) Hello,

I intend to use VPCH12-FL with a 1'' Germanium window in a waterproof IR camera prototype.

What do you suggest to use as counter flange? YLohia

(posted 2019-10-24 09:51:57.0) Hello, thank you for contacting Thorlabs. The VFA275 would be an appropriate flange mounting adapter for the VPCH12-FL. btyee

(posted 2017-05-12 07:41:16.66) Is there a good option to integrate a lens (plano-convex) with a CF flange? For VPCH12-FL, it seems that most lenses are simply not thick enough at the edges. tfrisch

(posted 2017-05-17 04:40:10.0) Hello, thank you for contacting Thorlabs. Mounting a lens in a conflat is not a common application. Typically the lens would be mounted inside or outside the chamber if necessary. I will contact you directly to discuss mounting solutions such as VFA275. Joseph.E.Roser

(posted 2017-04-06 15:03:08.223) I would also be interested in this product in a double-sided CF flange.

Is it possible to use a thinner window and two o-rings for a vacuum seal on the chamber side and on the faceplate side of the window? tfrisch

(posted 2017-04-19 03:51:21.0) Hello, thank you for contacting Thorlabs. While at low pressures, the pressure differential is the most important quantity, we do not have the necessary equipment to test your unique configuration, and these flanges are designed such that the inside pressure is low and the outside pressure is about 1atm. I will reach out to you to discuss my concerns, but at the very least, there is not an appropriate seat for an O-ring on the reverse side. vittorgd

(posted 2015-03-24 19:18:38.87) What are the part numbers for the actual windows provided in the VPCH312, 412, and 512? jlow

(posted 2015-03-26 11:08:39.0) Response from Jeremy at Thorlabs: The part numbers are WG31050, WG41050, and WG51050. mmichan

(posted 2014-05-08 17:52:15.923) Would you consider making this product in a double CF flange? besembeson

(posted 2014-05-15 08:44:25.0) Response from Bweh E at Thorlabs: Thanks for contacting Thorlabs. This is a good suggestion. We will look into this option and I will update you via email regarding this. |

- Ø2.75" CF Flange (Includes One O-Ring)

- Compatible with Ø1" Windows

- Not Compatible with Wedged Windows

Thorlabs' Ø2.75” CF flange does not include a window but is compatible with any Thorlabs Ø1" window that is 4.9 to 5.15 mm thick. When combined with the appropriate window, this flange allows for optical access into high-vacuum (HV) systems down to 10-8 Torr. This fixed (non-rotating) flange has six 1/4" (M6) through holes for bolting onto any standard Ø2.75" CF flange. Please note that mounting hardware is not included.

The CF-style flange utilizes a knife-edge mechanism to create an airtight seal between mating pieces. To create the seal, a copper gasket (available below) is most often employed. As the bolts of the mating pair are tightened, the knife edge “bites” into the copper gasket, deforming it. The extruded metal fills all the machining marks and surface defects, which yields a leak-tight seal.

- Ø2.75" CF Viewport with Ø1" Windows

- Viton O-Ring Metal to Glass Seal

- Sapphire, CaF2, or UVFS Window Included

- Clear Aperture: Ø0.7125" (18 mm)

- Not Compatible with Wedged Windows

Thorlabs' Ø2.75” CF flange viewports allow for optical access into high-vacuum (HV) systems down to 10-8 Torr. These are fixed (non-rotating) flanges with Ø1" windows that provide a Ø0.7125" clear aperture. These viewports have six 1/4" (M6) through holes for bolting onto any standard Ø2.75" CF flange. Please note that mounting hardware is not included. Our HV CF viewports can be purchased with one of three uncoated windows: sapphire, CaF2, or UVFS. Additionally, the provided window may be replaced with any of our Ø1" windows that are 4.9 - 5.15 mm thick.

- VMH6 Stainless Steel (18-8) Mounting Hardware Set Includes:

- Six Bolts (Silver-Plated, 1/4"-28 x 1.50", 12-Point Heads)

- Six Nuts and Twelve Washers

- Single-Use Copper Gaskets for Forming a Seal Between Ø2.75" CF Flanges

- 101 Copper Alloy (99.99% Pure), OFHC (Oxygen-Free High Conductivity)

- VGC10: 1/4-Hard Copper Gaskets

- VGA10: Annealed Copper Gaskets

Thorlabs offers mounting hardware and single-use copper gaskets for mating Ø2.75" CF flanges. These flanges utilize a knife-edge mechanism to create an airtight seal between mating pieces. To create the seal, a copper gasket is most often employed. As the bolts of the mating pair are tightened, the knife edge bites into the copper gasket, deforming it. The extruded metal fills all the machining marks and surface defects, which yields a leak-tight seal.

1/4-hard and annealed copper gaskets are sold in sets of 10. We recommend the 1/4-hard copper gaskets for most applications; for more delicate devices, such as viewports, we recommend using the softer annealed copper gaskets to lower the chance of deformation in the optic due to stress in the flange. The set of stainless steel mounting hardware includes six silver-plated bolts, six nuts, and twelve washers. The silver plating on the bolts acts as a lubricant to prevent galling between the stainless steel surfaces of the bolt and the nut.

Instructions

First ensure the knife-edge mating surfaces of the CF flanges are free from debris or scratches. Then choose the desired bolt hole orientation and insert the gasket, aligning leak-test grooves on the flanges if present. Slide a washer onto the bolt, insert the bolt through the flanges, and add another washer before screwing on the nut. Hand tighten each bolt, then use two wrenches to hold the bolt head and turn the nut. Tighten the nuts gradually in 1/8 to 1/4 turn increments in an alternating crisscross star pattern until the desired tightness is reached. Following these steps will result in a reliable seal with even gasket compression and deformation.

Products Home

Products Home

Zoom

Zoom

High-Vacuum Viewports for Ø1" Flat Windows

High-Vacuum Viewports for Ø1" Flat Windows