Tape

- Black Masking Tape

- Color and Photoluminescent Vinyl Tape

- Double-Sided Adhesive Tape

- Conductive and Insulating Tapes

VTR-050

Red Vinyl Tape

VTG-050

Green Vinyl Tape

T205-1.0

Black Aluminum

Foil Tape

T743-2.0

Black Masking Tape

PLT2

Photoluminescent

Stickers (Shown

with the Lights off)

KAP22-075

Insulating Kapton Tape

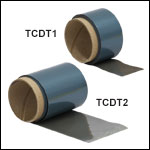

TCDT1

Thermally Conductive

Double-Sided Tape

DST1950

Double-Sided Tape

TCDT2

Please Wait

Thorlabs offers various types of tape for many different lab applications.

Our tape selections include the following:

- High-Performance or Standard Black Masking Tape

- Aluminum Foil Blackout Tape

- Colored Vinyl Tape (Red, Yellow, or Green)

- Double-Sided Adhesive Tape

- Double-Sided Conductive Tape

- Insulating Kapton Tape

- Photoluminescent Stickers

| Posted Comments: | |

Ivo Aubrecht

(posted 2019-06-18 07:34:13.99) What is the carrier of your black masking types? What is the thickness?

I would like to use a laser marker (at 1064nm, 10W) for cutting openings of various types in them and use them as masks in exposition of photoresist plates. Another application would be for defining an area of interest on a sample before its inspection by means of various devices - a microscope, a scatterometer, a spectrometer etc. In either case low tack and absolutely no residua after removing the mask is essential.

I have had some experience with a low tack black tape for advertising purposes which I use to minimize reflections by the rear side of a photoresist plate. I verified that I can cut the opening with that laser marker.

I would like to test your tapes too. I am planning to attend Laser World of ..2019 in Munich.

Would it be possible to get sample amounts of the types (some 50-100cm)?

Any recommendations which of the types would suit best? llamb

(posted 2019-06-18 09:21:43.0) Thank you for contacting Thorlabs. Our T137- tape is 0.0049" thick. Our T743- tape is 0.0065" thick. Our T205- tape is 0.0035" thick. I have reached out to you directly to discuss your application further and to discuss possible samples. |

Click to Enlarge

High-Performance Black Masking Tape

Click to Enlarge

Black Masking Tape

- 1" (25 mm) and 2" (50 mm) Wide Versions Available

- Paper-Based Masking Tape for General Purpose or Blackout Applications

- Aluminum Foil Tape for Total Blackout Applications

- Can be Torn by Hand and Removed Easily Without Leaving Residue

- Not Intended for Use in Laser Safety Applications

Thorlabs offers a standard and high-performance black masking tape, as well as an aluminum foil masking tape. All types of tape can be torn by hand, are easy to remove, and do not leave a residue. The T137-1.0 and T137-2.0 black masking tape can be used for general applications. For applications requiring minimal ambient light transmission, the T743-1.0 or T743-2.0 high-performance black masking tape is recommended. For total blackout requirements or high-power applications, we offer the T205-1.0 or T205-2.0 non-reflective, flame-retardant aluminum tape. This foil tape has been tested to withstand up to 10 seconds of exposure from a 20 W, Ø6 mm, 10.6 µm laser beam.

In the photographs shown above, a collimated LED (Item # M530L2-C2) with approximately 170 mW output power was used to illustrate how the T743-2.0 high-performance tape allows very little light transmission as compared to the T137-2.0 standard black masking tape. The table below gives the measured power and percent transmittance when various wavelengths of light were incident upon each type of tape.

| Black Tape Performance | |||

|---|---|---|---|

| Incident Power | Measured Output Power (% Transmittance) | ||

| T137-2.0 Masking Tape | T743-2.0 High-Performance Masking Tape | T205-2.0 Aluminum Foil Tape | |

| 1.07 mW at 635 nm | 1.34 µW (0.13%) | 0.90 µW (0.08%) | Zero (0%) |

| 4.79 mW at 635 nm | 5.92 µW (0.12%) | 0.24 µW (<0.01%) | Zero (0%) |

| 1.41 mW at 632.991a | 3.36 µW (0.24%) | 0.012 µW (<0.01%) | Zero (0%) |

| 20.34 mW at 850 nmb | 28.74 µW (0.14%) | 1.04 µW (<0.01%) | 0.0006 µW (<1 x 10-5%) |

- 1/2" (12.7 mm) Wide Vinyl Tape

- 108' (32.9 m) Long Roll

- Available in Red, Green, or Yellow

Colored rolls of vinyl tape are ideal for color coding fibers cables, electrical cables, tools, and samples. The semi-gloss finish can be written on with permanent marker, and the tape can be used in environments from 40 °F to 170 °F (5 °C to 76 °C), although it is best to apply the tape at room temperature.

- White, Double-Sided Tape with 3M Adhesive 375

- 10.2 mils (0.26 mm) Thick, 19 mm Wide, 50 m Long

- Bonds on Contact to Almost any Surface

- Bonds are Durable with High Peel and Shear Strength

- Resistance to UV Light, Solvents, Plasticizers, and High Temperatures

This 3M tape is 10.2 mils (0.26 mm) thick, double-coated with 375 adhesive, and is made from PVC. The tape features a high peel and shear strength, excellent resistance to UV light, good solvent and plasticizer resistance, and long-term temperature performance up to 158 °F. There are many applications for the tape including mounting optics, hardware, fiber, sensors, etc.

- Thermally Conductive Double-Sided Acrylic Adhesive Tape

- 0.009" (0.229 mm) Thick

- Two Options:

- TCDT1: 1" Wide x 48" Long (25.4 mm x 1219 mm)

- TCDT2: 2" Wide x 24" Long (50.8 mm 610 mm)

- Great Alternative to Heat-Cured Adhesives, Screw Mounting, or Clip Mounting

- Provides a High Bond Strength to a Variety of Surfaces

- Can be Removed without Damaging Parts

The thermally conductive, double-sided tape consists of a superior bond strength, pressure-sensitive acrylic adhesive loaded with titanium diboride and applied to an expanded aluminum carrier. The tape is embossed with an innovative pattern for maximum conformability and minimal air pockets and offers excellent thermal, mechanical, environmental, and chemical properties. Our thermally conductive double-sided tape can bond heat sinks and thermal plates to components without the use of clips, screws, other mechanical fasteners, or additional thermal compounds and can be removed after the application without damage to the component.

| Item # | TCDT1 | TCDT2 |

|---|---|---|

| Construction | ||

| Carrier | Expanded Al | |

| Color | Grey | |

| Thickness | 0.009" ± 0.001" (0.229 mm ± 0.03 mm) | |

| Thermal | ||

| Thermal Impedance @ <1 psi | 0.25 °C-in2/W (1.7 °C-cm2/W) | |

| Thermal Conductivity | 1.40 W/m-K | |

| Electrical | ||

| Voltage Breakdown | NA | |

| Volume Resistivity | 0.013 ohm-cm | |

| Flammability Rating (E140244) | Not Rated | |

| Lap Shear Adhesion | 70 psi (0.483 MPa) | |

| Item # | TCDT1 | TCDT2 | |

|---|---|---|---|

| Mechanical | |||

| Die Shear Adhesion |

|||

| Aluminum | 135 psi (0.931 MPa) @ 25 °C 25 psi (0.172 MPa) @ 150 °C |

||

| Copper | 115 psi (0.793 MPa) @ 25 °C 35 psi (0.241 MPa) @ 150 °C |

||

| Aluminum Oxide | 125 psi (0.862 MPa) @ 25 °C 40 psi (0.276 MPa) @ 150 °C |

||

| Creep Adhesion |

|||

| 25°C, 12 psi (0.083 MPa) | >50 days | ||

| 150°C, 12 psi (0.083 MPa) | >50 days | ||

| Adhesive CTE, -40 to 150 °C | 400 ppm/°C | ||

| Dimensions | 1" x 48" (25.4 mm x 1219 mm) |

2" x 24" (50.8 mm x 610 mm) |

|

| Specifications | |

|---|---|

| Width | 3/4" (1.9 cm) |

| Length | 36 yds (32.9 m) |

| Kapton Type | HN |

| Film Thickness | 1.0 Mil (0.03 mm) |

| Total Thickness | 2.5 Mil (0.07 mm) |

| Color | Amber |

| Adhesive | Cross-Linked Silicon |

| Breaking Strengtha | 30 lb/in (5.4 kg/cm) |

| Elongation at Break | 60% |

| Adhesion to Steel | 18 oz/in (200 g/cm) |

| Dielectric Strength | 7,500 Volts |

| Insulation Class | 356 °F (180 °C) |

| Temperature Rangeb | -100 °F to 500 °F (-73 °C to 260 °C) |

| Storage Conditions | Dry Location between 55 °F and 85 °F (13 °C and 30 °C) |

- Removes Easily without Leaving a Residue

- Wide Usage Range: -100 °F to 500 °F (-73°C to 260 °C)

- Substitute for Standard Electrical Tape in Cooled and Heated Environments

- Excellent for Insulation, Masking, or Packaging Applications

This high-temperature tape is made from Dupont's trademark Kapton film and a cross-linked silicon adhesive. The tape is flame-resistant, will withstand short-term intermittent temperatures to 600 °F, and can be used as electrical and thermal insulation. Compared to electrical tape, it removes easily without leaving a residue, making it ideal for packing, temporarily securing components, or powder coating applications.

Kapton tape is commonly used as a wire and cable wrap as well as to protect electrical components during soldering. It is effective for both hand-soldering and mass soldering applications, such as wave soldering. In the electronics industry, Kapton tape is applied to circuit boards before wave soldering to shield gold fingers from the solder material and prevent unwanted electrical connections. The tape is also easy to trim with a razor blade and can be used as a temporary dust cover for ports in devices.

Click to Enlarge

PLT2 Shown with the Lights Off

Click to Enlarge

PLT2 Shown with the Lights On

- Ideal for Dark Rooms

- Mark Equipment, Doorways, Walkways, or Table Edges

- 100 Ø1/2" (Ø12.7 mm) Sticker Dots per Roll

- Glow Time of up to 12 Hours

These vinyl photoluminescent stickers are ideal for marking doorways, table edges, and walkways, making movement within a dark room safer and easier. They can also be used to make it easier to locate equipment in a dark room. Each roll contains 100 Ø1/2" (Ø12.7 mm) photoluminescent sticker dots that have a glow time of up to 12 hours. Shown to the right is a comparison of how the photoluminescent dots appear with the lights on and off.

Each sticker charges in under three minutes. For information regarding the charge and glow times of these photoluminescent stickers, please click on the red docs icon below.

Products Home

Products Home

Zoom

Zoom

Tape

Tape