Precision Kinematic Mirror Mounts

- Ø1/2", Ø1", Ø2", Ø3", & Ø4" Mounts Available

- High-Precision Differential Adjusters Available

KS05

Ø1/2" Mirror Mount

KS1TV

Ø1" Vacuum-Compatible Mirror Mount

KS1T

Internally SM1-Threaded Ø1" Mirror Mount

KS2D

High-Resolution

Ø2" Differential

Adjuster Mirror Mount

KS3

Ø3" Mirror Mount

Please Wait

Vacuum-Compatible Components

Many of our optomechanical components can be special ordered for vacuum use. Contact techsupport@thorlabs.com for details.

Features

- Thicker Back Plate and Stiffer Springs Provide Increased Stability Compared to our Two Adjuster Kinematic Mounts

- Kinematic Mounts Available for Ø1/2", Ø1", Ø2", Ø3", and Ø4" Optics

- ±4° of Pitch and Yaw Adjustment

- Lockable Adjusters Available for Ø1/2", Ø1", Ø2", Ø3" and Ø4" Optic Mounts

- Differential Adjuster Versions Available for Ø1" and Ø2" Optical Mounts

- SM-Threaded Options Available for Ø1/2", Ø1", and Ø2" Optical Mounts

- Vacuum-Compatible SM1-Threaded Mount for Ø1" Optical Mount

- Mounting Holes at 90º Enable Left-Handed or Right-Handed Operation

- Off-Center Mounting Options (Excludes KS05, KS05K, KS05T, KS1, and KS1T)

These Precision Kinematic Mirror Mounts take advantage of a rigid mechanical design to achieve long-term stability. Compared to our standard Two Adjuster Kinematic Mirror Mounts, these three adjuster mounts incorporate a thicker back plate and stiffer springs. The lockable adjusters reduce drift for long-term stable operation in all of our mounts except for the KS1TV vacuum-compatible kinematic mount. Locking the adjusters on this mount require installing POLARIS-LN1 lock nuts (not included). All of the mounts featured on this page offer ±4° of angular adjustment.

Three-adjuster mounts come with either standard or differential adjusters. Standard adjusters are 3/16"-100, 1/4"-80, or 1/4"-100 threaded screws, depending on mount size, with a stainless steel ball tip. The KS1D Ø1" kinematic mount and KS2D Ø2" kinematic mount are offered with differential pitch and yaw adjusters, which enabling very fine angular adjustments. Our differential adjusters allow for minimum angular movements of 2.91 μrad and 1.45 μrad for the KS1D and KS2D mounts, respectively (see below for more details).

Mounts on this page feature two optic retention methods. Kinematic mounts for Ø1/2", Ø1", Ø2", Ø3", and Ø4" optical elements are available with side optic retention via a nylon-tipped set screw. Ø1/2", Ø1", and Ø2" mounts are available with SM-threaded optic cells for compatibility with our lens tubes.

Thorlabs offers a variety of other two and three adjuster mirror mounts including our high-stability Polaris® Mirror Mounts.

| Item # | Optic Diameter | Minimum Optic Thickness |

Optical Axis Height | Angular Adjustment | Number of Adjusters | Type of Adjusters | Adjuster Thread |

Resolutiona | Clear Apertureb | Mounting |

|---|---|---|---|---|---|---|---|---|---|---|

| KS05(/M) | 1/2" or 12.0 mm |

0.12" (3.0 mm) |

0.58" (14.7 mm) |

±4º | 3 | Hex Socket | 3/16"-100 | 9.1 mrad/rev | Ø0.47" (Ø11.9 mm) |

8-32 (M4) Tapped Holes, 2 Places |

| KS05K(/M) | 1/2" or 12.0 mm |

0.12" (3.0 mm) |

0.58" (14.7 mm) |

±4º | 3 | Removable Knobs | 3/16"-100 | 9.1 mrad/rev | Ø0.47" (Ø11.9 mm) |

8-32 (M4) Tapped Holes, 2 Places |

| KS05T(/M)c | 1/2" or 12.0 mm |

0.16"d (4.1 mm) |

0.58" (14.7 mm) |

±4º | 3 | Hex Socket | 3/16"-100 | 9.1 mrad/rev | Ø0.44" (Ø11.2 mm) |

8-32 (M4) Tapped Holes, 2 Places |

| KS1 | 1" or 25.0 mm |

0.16" (4.1 mm) |

1.0" (25.4 mm) |

±4º | 3 | Removable Knobs | 1/4"-80 | 7.4 mrad/rev | Ø0.94" (Ø23.9 mm) |

#8 (M4) Counterbored Holes, 2 Places |

| KS1Tc | 1" or 25.0 mm |

0.14"d (3.6 mm) |

1.0" (25.4 mm) |

±4º | 3 | Removable Knobs | 1/4"-80 | 7.4 mrad/rev | Ø0.90" (Ø22.9 mm) |

#8 (M4) Counterbored Holes, 2 Places |

| KS1TV | 1" or 25.0 mm |

0.28"d (7.11 mm) |

1.0" (25.4 mm) |

±4º | 3 | Removable Knobs | 1/4"-100 | 9.3 mrad/rev | Ø0.90" (Ø22.9 mm) |

#8 (M4) Counterbored Holes, 2 Places |

| KS2 | 2" or 50.0 mm |

0.20" (5.1 mm) |

1.56" (39.6 mm) |

±4º | 3 | Removable Knobs | 1/4"-80 | 4.8 mrad/rev | Ø1.94" (Ø49.3 mm) |

#8 (M4) Counterbored Holes, 6 Places |

| KS2Tc | 2" or 50.0 mm |

0.10"d (2.5 mm) |

1.81" (46.0 mm) |

±4º | 3 | Removable Knobs | 1/4"-80 | 4.8 mrad/rev | Ø1.90" (Ø48.3 mm) |

#8 (M4) Counterbored Holes, 6 Places |

| KS3 | 3" or 75.0 mm |

0.28" (7.1 mm) |

2.13" (54.1 mm) |

±4º | 2 | Removable Knobs | 1/4"-80 | 5.0 mrad/rev | Ø2.82" (Ø71.6 mm) |

#8 (M4) Counterbored Holes, 4 Places |

| KS4 | 4" or 100.0 mm |

0.28" (7.1 mm) |

2.70" (69.0 mm) |

±4º | 2 | Removable Knobs | 1/4"-80 | 3.9 mrad/rev | Ø3.94" (Ø100.1 mm) |

#8 (M4) Counterbored Holes, 4 Places |

| KS1D | 1" or 25.0 mm |

0.16" (4.1 mm) |

1.0" (25.4 mm) |

±4º | 3 | Removable Knobs | 1/4"-80 / M3 x 0.40 / M3 x 0.375e |

660 μrad/rev | Ø0.94" (Ø23.9 mm) |

#8 (M4) Counterbored Holes, 2 Places |

| KS2D | 2" or 50.0 mm |

0.20" (5.1 mm) |

1.56" (39.6 mm) |

±4º | 3 | Removable Knobs | 1/4"-80 / M3 x 0.40 / M3 x 0.375e |

400 μrad/rev | Ø1.94" (Ø49.3 mm) |

#8 (M4) Counterbored Holes, 6 Places |

Click to Enlarge

Shown above is the KS2D Ø2" Differential Adjuster Mirror Mount with Provided Hex Key

Differential Adjuster

The KS1D and KS2D come with two differential adjusters and one conventional adjuster. The differential adjuster is actuated using either the provided removable hex wrench for fine adjustment or the black aluminum knob for coarse adjustment. The total angular adjustment using the conventional adjusters is ±4° for both the KS1D and KS2D. The angular adjustment using only the differential adjusters is ±1.5° and ±0.9° for the KS1D and KS2D, respectively.

Both the KS1D and KS2D use two DAS110 differential adjusters (locking ring not included with KS1D and KS2D), which offer 318 μm of coarse and 25 μm of fine differential movement. A schematic of the differential mechanism is shown below.

Coarse Adjustment

Referring to the drawing below, knob "A" is fastened to the 1/4"-80 externally threaded main body "B" and provides the coarse angular adjustment of the kinematic mount, shown below. The knob can be removed to expose a 5/64" hex socket, which can also be used for coarse adjustments. The coarse adjuster (1/4"-80 threaded main body) is standard on all precision mounts except the KS05(/M) and KS05K(/M), which each feature a 3/16"-100 threaded main body.

Click for Details

Schematic of the Differential Adjuster Mechanism

Fine Adjustment

The main body "B" is internally threaded with an M3 x 0.40 thread. This thread holds the intermediate actuator "C", which can be rotated by a hex wrench. The intermediate actuator is both internally and externally threaded, allowing a differential movement to be achieved between parts "C" and the push rod "D".

The external thread of "C" is the same M3 x 0.40 mm thread internal to the main body. When the intermediate actuator is rotated clockwise, it moves out of the main body by 400 μm per revolution. The push rod "D" is connected to the internal thread of "C" via an M3 x 0.373 thread and is restricted from rotating by the main body "B". As "C" is rotated, it advances at the rate of 400 μm/rev, while the push rod retreats at 375 μm/rev. This results in a "differential" motion of the push rod that is equal to the net difference of the pitch of the two threads for total displacement of 25 μm/rev.

| Posted Comments: | |

Timo Junker

(posted 2020-12-22 00:48:15.44) Hello,

how is the Beam Deviation After Thermal Cycling of KS05/M and KS1D compared to the Polaris Mounts?

Thank you vwery much

Timo Junker llamb

(posted 2020-12-23 03:09:59.0) Hi Timo, thank you for contacting Thorlabs. Generally, our aluminum mounts are designed for general purpose applications at room temperature, so they will not perform nearly as well as the Polaris mounts in terms of Beam Deviation after thermal cycling. While not explicit to the KS05/M or KS1D, I will reach out to you directly with some data we have comparing Polaris mounts to our aluminum mounts. Dimitar Slavov

(posted 2020-10-06 09:51:52.263) Dear colleagues,

May I have from you a copy of the KS2 solid works file for Solid Works 2013 or older version. In difference to the files for other mounts that I have downloaded from your pages, that one can not be opened by my software.

Thank you in advance llamb

(posted 2020-10-09 08:14:44.0) Thank you for contacting Thorlabs. As SolidWorks does not allow saving files as previous versions, I would instead recommend trying the KS2's Step File, which will not have the same version restrictions that the pure SolidWorks file may have. I have reached out to you directly as well. abc124771

(posted 2018-12-12 04:07:56.877) Can KS3 be available in 1"? I basically require 2 or 3 adjuster kinematic mounts which can be brought as close to each other as possible. The regular KM100 mounts have small projections on the front plate which prevents two such plates to be brought too close together. Which mounts would you suggest for my purpose? Also the aperture of the mounts has to be clear from the back since I need transmission too. YLohia

(posted 2018-12-12 12:41:21.0) The 1" version of the KS3 is already available on this page with the part number KS1. For transmission and close proximity of two plates, we recommend looking into the KS1CE. andy.violette

(posted 2017-11-13 12:03:47.33) Is it required to mount the KS1D to 3 surfaces, rather than just 2 (where the mounting bolts are), for precision, thanks nbayconich

(posted 2017-12-20 10:13:41.0) Thank you for contacting Thorlabs. We have found that using 2 mounting surfaces is sufficient for most applications. If ultra precision is of concern we would recommend the polaris series of mounts which include dowel holes for alignment. I will reach out to you directly about your application. user

(posted 2016-07-21 16:32:26.083) On the `How it Works' tab, in the second sentence under `Coarse Adjustment', it is written `5/64" kex socket' instead of hex socket. nicolas.perlot

(posted 2015-12-18 23:33:50.27) Does KS1 (resp. KS2) differ from KS1D (resp. KS2D) only by the adjusters?

If I have a KS1 and a KS1D, can I interchange the adjusters? And can I use motorized actuators such as Z812 on both KS1 and KS1D? Thanks. jlow

(posted 2015-12-21 04:57:07.0) Response from Jeremy at Thorlabs: The only difference between the two would be the adjusters. The adjusters can be taken off and replaced with other actuators that has 1/4"-80 thread, such as the Z812. mcmasterbm

(posted 2014-10-20 08:15:47.98) Please tell me what the standard lubricant is? I need a low outgassing PTFE based lubricant rather than a petroleum lube.

I'd also like a clear anodize version.

Please tell me what I would need to order this option.

Thanks. jlow

(posted 2014-10-22 04:14:17.0) Response from Jeremy at Thorlabs: The grease we typically use for these is a mixture of Apiezon M and Nye PG-44A grease. We can quote these with other type of grease and clear anodization as well. I will contact you directly for the quote. You can also contact us at techsupport@thorlabs.com for quotes in the future. user

(posted 2014-01-07 12:05:55.273) I would like to know the pitch of the thread of a KS4 mirror mount. You've stated the thread type but this thread can be fine or superfine, having different pitch... jlow

(posted 2014-01-07 08:28:56.0) Response from Jeremy at Thorlabs: The KS4 uses 1/4"-80 adjusters so the screw pitch would be 1/80 of an inch (0.3175mm). hambitza

(posted 2013-06-26 14:05:38.307) I know that the resolution of a mirror mount is usually determined by the pitch size of the screw. However, I am asking myself in which steps I can actually turn the screw. For example, could I turn the screw by 5 or 10 degree by hand? For me the final resolution would be determined by the fine adjustment steps in which I can change the mirror angle. cdaly

(posted 2013-07-02 11:02:00.0) Response from Chris at Thorlabs: Thank you for using our feedback tool. This is somewhat subjective to the ability of the user, but with a simple hex key rather than a ball driver, it should be possible to get somewhere in the range of 2-6 degrees of revolution of the lead screws pretty reliably. bdada

(posted 2012-02-13 15:19:00.0) Response from Buki at Thorlabs:

Thank you for your valuable feedback on the KS1 and KM100 families. I have brought up your idea of a standard mounting screw with our design engineers. We do not have your contact information, so please email TechSupport@thorlabs to discuss this matter further. user

(posted 2012-02-11 16:26:01.0) I mix different mirror mounts in the KS1 and KM100 families, the mounting screw has a different length for each family, would you consider making one standard. Murphy's law comes into play here as i always have the wrong screw. bdada

(posted 2011-11-07 14:10:00.0) Response from Buki at Thorlabs:

Thank you for participating in our Feedback Forum. The Polaris is designed to provide the ultimate in thermal stability so we expect it to perform better than our Ultra Stable Kinematic Mirror Mounts. We will run some tests to compare the performance of the Polaris to these mounts. Please contact TechSupport@thorlabs.com if you have further questions. user

(posted 2011-11-05 00:52:46.0) Can you do thermal testing on these mounts so I can compare to the Polaris. I think they might be just as good but not sure. jpang

(posted 2007-12-19 10:34:48.0) It would be helpful to have all maximum angular range listed for all your kinematic mirror mounts. |

- Optics Secured in Double-Bored Hole with Nylon-Tipped Setscrew

- Thick Back Plate and Heavy-Duty Springs for Stability

- Fabricated from Black Anodized Aluminum

- Hardened Stainless Steel Inserts at Kinematic Contacts Reduce Wear

- Available With or Without Knobs

These Precision Kinematic Mirror Mounts are designed for use with either Ø1/2” or Ø12.0 mm optics, are available with or without removable knobs, and provide ±4° of pitch and yaw adjustment. They incorporate thicker back plates than our two adjuster mirror mounts, thereby providing increased stability. In addition to the increased mass of the mount, stiffer springs and hardened inserts at all contact points have been incorporated to enhance the overall performance.

The three 3/16"-100 TPI adjusters on each mount allow the ±4º adjustment range to be altered by translating the front plate of the mirror mount. The spacing between the front and back plate of the mirror mount must be 0.065" (1.65 mm) for the adjustment range to be symmetric (i.e., ±4°). When using all three adjusters, 0.250" (6.35 mm) of linear Z translation can be achieved with the KS05(/M), while 0.18" (4.57 mm) is possible with the KS05K(/M). There are two 8-32 (M4) tapped mounting holes located on the mount, which allow for post mounting in either left- or right-handed orientations.

Both the KS05(/M) and KS05K(/M) incorporate three 3/16"-100 lockable adjusters. The adjusters on the KS05(/M) are 0.5" long, while those on the KS05K(/M) are 0.75" long. The hex-driven design of the KS05(/M) allows it to fit into smaller areas where most Ø1/2" optic mounts cannot. The KS05K(/M), however, has removable 3/16"-100 black aluminum knobs that offer more comfort and allow for it to be used in setups where a balldriver or hex tool cannot be used.

| Item # | Optic Diameter | Minimum Optic Thickness | Optical Axis Height | Angular Adjustment | Number of Adjusters | Type of Adjustersa | Adjuster Thread |

Clear Aperture | Mounting |

|---|---|---|---|---|---|---|---|---|---|

| KS05(/M) | 1/2" or 12.0 mm |

0.12" (3.0 mm) |

0.58" (14.7 mm) |

±4º | 3 | Hex Socket | 3/16"-100 | Ø0.47" (Ø11.9 mm) |

8-32 (M4) Tapped Holes, 2 Places |

| KS05K(/M) | 1/2" or 12.0 mm |

0.12" (3.0 mm) |

0.58" (14.7 mm) |

±4º | 3 | Removable Knobs | 3/16"-100 | Ø0.47" (Ø11.9 mm) |

8-32 (M4) Tapped Holes, 2 Places |

- Internally SM05-Threaded (0.535"-40) Optic Cell for Ø1/2" Lens Tube Compatibility

- Mounts Thin Ø1/2" Optics via Included Retaining Rings

- 8-32 (M4) Tapped Holes Allow for Left-Handed or Right-Handed Orientation

- Thick Back Plate and Heavy-Duty Springs for Stability

- Fabricated from Black Anodized Aluminum

- Hardened Stainless Steel Inserts at Kinematic Contacts Reduce Wear

Our KS05T(/M) Threaded Precision Kinematic Mirror Mount is designed for use with either Ø1/2” or Ø12.0 mm optics and provides ±4° of pitch and yaw adjustment. For low-stress mounting, two SM05RR retaining rings are included, allowing the optic to be secured using an SPW603 Spanner Wrench. Stainless steel adjuster screws with brass bushings provide smooth adjustment.

These mounts incorporate thicker back plates than our two adjuster mirror mounts, thereby providing increased stability. In addition to the increased mass of the mount, stiffer springs and hardened inserts at all contact points have been utilized to enhance the overall performance. An internally SM05-threaded (0.535"-40) optic cell enables compatibility with Ø1/2" lens tubes, as shown in the image to the right.

Each mount contains three 3/16"-100 TPI, lockable adjusters that allow the ±4° adjustment range to be altered by translating the front plate of the mirror mount. The spacing between the front and back plate of the mirror mount must be 0.065" (1.65 mm) for the adjustment range to be symmetric (i.e., ±4°). When using all three adjusters, 0.250" (6.35 mm) of linear Z translation can be achieved.

| Item # | Optic Diameter | Maximum Optic Thickness | Optical Axis Height | Angular Adjustment | Number of Adjusters | Type of Adjustersa | Adjuster Thread |

Clear Aperture | Mounting |

|---|---|---|---|---|---|---|---|---|---|

| KS05T(/M) | 1/2" or 12.0 mm |

0.16" (4.1 mm) |

0.58" (14.7 mm) |

±4º | 3 | Hex Socket | 3/16"-100 | Ø0.44" (Ø11.2 mm) |

8-32 (M4) Tapped Holes, 2 Places |

Click to Enlarge Mirror in KS1 Kinematic Mount is Centered over the Post Rotation Axis using the KMCP Variable Centering Plate

- Optics Secured in Double-Bored Hole with Nylon-Tipped Setscrew

- Thick Back Plate and Heavy-Duty Springs for Stability

- Fabricated from Black Anodized Aluminum

- Hardened Stainless Steel Inserts at Kinematic Contacts Reduce Wear

The KS1 and KS2 Precision Kinematic Mirror Mounts are designed to hold Ø1" (or Ø25 mm) and Ø2" (or Ø50 mm) optics, respectively, and provide ±4° of pitch and yaw adjustment. The optic is held by a nylon-tipped setscrew, and pretension screws minimize beam shift when locking. Stainless steel lead screws with brass bushings provide smooth adjustment. Counterbored mounting holes allow for post mounting in either left- or right-handed orientations.

These mounts incorporate thicker back plates than our two adjuster mirror mounts, thereby providing increased stability. In addition to the increased mass of the mount, stiffer springs and hardened inserts at all contact points have been utilized to enhance the overall performance.

The three 1/4"-80 TPI, lockable adjusters allow the ±4º adjustment range to be altered by translating the front plate of the mirror mount. The spacing between the front and back plate must be 0.120" (3.05 mm) and 0.190" (4.83 mm) for the KS1 and KS2 mirror mounts, respectively, for the adjustment range to be symmetric (i.e., ±4°). When using all three adjusters, the Ø1" and Ø2" precision kinematic mounts can achieve a maximum Z translation of 0.25" (6.4 mm).

| Item # | Optic Diameter | Minimum Optic Thickness | Optical Axis Height | Angular Adjustment | Number of Adjusters | Type of Adjustersa | Adjuster Thread |

Mounting |

|---|---|---|---|---|---|---|---|---|

| KS1 | 1" or 25.0 mm |

0.16" (4.1 mm) |

1.0" (25.4 mm) |

±4º | 3 | Removable Knobs | 1/4"-80 | #8 (M4) Counterbored Holes, 2 Places |

| KS2 | 2" or 50.0 mm |

0.20" (5.1 mm) |

1.56" (39.6 mm) |

±4º | 3 | Removable Knobs | 1/4"-80 | #8 (M4) Counterbored Holes, 6 Places |

- Internally SM1- (1.035"-40) or SM2-Threaded (2.035"-40) Optic Cell for Lens Tube Compatibility

- Mounts Thin Ø1" or Ø2" Optics via Included Retaining Rings

- Counterbored #8 (M4) Through Holes Allow for Left-Handed or Right-Handed Orientation

- Thick Back Plate and Heavy-Duty Springs for Stability

- Fabricated from Black Anodized Aluminum

- Hardened Stainless Steel Inserts at Kinematic Contacts Reduce Wear

The KS1T and KS2T Threaded Precision Kinematic Mirror Mounts are designed to hold thin Ø1" (or Ø25 mm) and Ø2" (or Ø50 mm) optics, respectively, and provide ±4° of pitch and yaw adjustment. The optic is held in place using the two included SM1RR (KS1T) or SM2RR (KS2T) retaining rings for low-stress mounting. The SM1RR retaining rings can be attached using an SPW606 while the SM2RR retaining rings can be attached by using an SPW604 Spanner Wrench. Stainless steel lead screws with brass bushings provide smooth adjustment. Counterbored mounting holes allow for post mounting in either left- or right-handed orientations.

These mounts incorporate thicker back plates than our two adjuster mirror mounts, thereby providing increased stability. In addition to the increased mass of the mount, stiffer springs and hardened inserts at all contact points have been utilized to enhance the overall performance. The KS1T has an internally SM1-threaded (1.035"-40) optic cell, making it compatible with Ø1" lens tubes, while the KS2T has an internally SM2-threaded (2.035"-40) optic cell for compatibility with Ø2" lens tubes. As shown in the image above and to the right, the internal threads can also be used to mount externally threaded adapters, allowing for various components to be mounted such as laser diode modules or fiber collimators.

Each mount contains three 1/4"-80 TPI, lockable adjusters that allow the ±4º adjustment range to be altered by translating the front plate of the mirror mount. The spacing between the front and back plate must be 0.120" (3.05 mm) and 0.190" (4.83 mm) for the KS1T and KS2T mirror mounts, respectively, for the adjustment range to be symmetric (i.e., ±4°). When using all three adjusters, the Ø1" and Ø2" precision kinematic mounts can achieve a maximum Z translation of 0.25" (6.4 mm).

| Item # | Optic Diameter | Maximum Optic Thickness | Internal Threading | Optical Axis Height | Angular Adjustment | Number of Adjusters | Type of Adjustersa | Adjuster Thread |

Mounting |

|---|---|---|---|---|---|---|---|---|---|

| KS1T | 1" or 25.0 mm |

0.14" (3.6 mm) |

SM1 (1.035"-40) |

1.0" (25.4 mm) |

±4º | 3 | Removable Knobs | 1/4"-80 | #8 (M4) Counterbored Holes, 2 Places |

| KS2T | 2" or 50.0 mm |

0.10" (2.5 mm) |

SM2 (2.035"-40) |

1.81" (46.0 mm) |

±4º | 3 | Removable Knobs | 1/4"-80 | #8 (M4) Counterbored Holes, 6 Places |

Click to Enlarge

Click to EnlargeFront View

- Internally SM1-Threaded (1.035"-40) Optic Cell

- Mount Ø1" Optics Up to 0.28" (7.1 mm) Thick Using Included Retaining Ring

- Counterbored #8 (M4) Through Holes Allow for Left-Handed or Right-Handed Orientation

- Compatible with >10-6 Torr Environments Directly Out of the Packaging

The KS1TV SM1-Threaded Vacuum-Compatible Kinematic Mirror Mount is designed to hold Ø1" (or Ø25 mm) optics up to 0.28" (7.1 mm) thick and provides ±4° of pitch and yaw adjustment. The optic is held in place using the included vacuum-compatible retaining ring. The retaining ring can be attached using an SPW606 spanner wrench. Stainless steel lead screws with phosphor bronze bushings provide smooth adjustment. #8 (M4) counterbored mounting holes allow for post mounting in either left- or right-handed orientations.

This mount incorporates a thicker back plate than our two adjuster mirror mounts, thereby providing increased stability. In addition to the increased mass of the mount, stiffer springs and hardened inserts at all contact points have been utilized to enhance the overall performance. The KS1TV has an internally SM1-threaded (1.035"-40) optic cell.

This mount contains three 1/4"-100 TPI adjusters that allow the ±4º adjustment range to be altered by translating the front plate of the mirror mount. The spacing between the front and back plate must be 0.120" (3.05 mm) for the adjustment range to be symmetric (i.e., ±4°). When using all three adjusters, the mount can achieve a maximum Z translation of 0.25" (6.4 mm). The adjusters can be locked by installing POLARIS-LN1 lock nuts (not included). Each adjuster can be removed and replaced with our PIAK10VF vacuum-compatible piezoelectric inertia actuators, as shown in the image to the right, enabling angular adjustments with a typical resolution of 0.5 µrad.

Vacuum Compatibility Information

This vacuum-compatible mount is chemically cleaned and prepared for vacuum applications before packaging. It is compatible directly out of the packaging with vacuum environments down to 10-6 Torr. With additional cleaning and processing, it can be used at even lower pressures, only limited by the outgassing rate of the constituent parts. The 6061-T6 aluminum body of the mount has the highest outgassing rate of the materials used. The material properties of the mount and the cleaning methods completed by the end user should be used to determine the appropriateness of using this mount and its materials in a specific vacuum system.

| Item # | Optic Diameter | Maximum Optic Thickness | Optical Axis Height | Angular Adjustment | Number of Adjusters | Type of Adjustersa | Adjuster Thread |

Clear Aperture | Mounting |

|---|---|---|---|---|---|---|---|---|---|

| KS1TV | 1" or 25.0 mm |

0.28" (7.11 mm) |

1.00" (25.4 mm) |

±4º | 3 | Removable Knobs |

1/4"-100 | Ø0.90" (Ø22.9 mm) |

#8 (M4) Counterbored Holes, 2 Places |

Click for Details

Schematic of the Differential Adjuster Mechanism. For more details on the internal operation of the differential adjustment mechanism, please see the How it Works tab above.

- Optics Secured in Double Bored Hole with Nylon-Tipped Setscrew

- Thick Back Plate and Heavy-Duty Springs for Stability

- Fabricated from Black Anodized Aluminum

- Hardened Stainless Steel Inserts at Kinematic Contacts to Reduce Wear

These Ø1” and Ø2” kinematic mirror mounts feature locking differential adjusters and a stable mechanical package, which provide long-term stability compared to the two adjuster mirror mounts. The KS1D and KS2D Kinematic Mirror Mounts can hold Ø1" or Ø25 mm, and Ø2" or Ø50 mm optics, respectively. The angular adjustment range is ±4º when the spacing between the front and back plate of the mirror mount is 0.120" (3.05 mm) for the KS1D and 0.190" (4.83 mm) for the KS2D. When using all three adjusters, these mounts can achieve a maximum Z translation of 0.25" (6.4 mm).

Two of each mount's three adjusters incorporate our differential drive mechanism (see the How it Works tab above for details). This high resolution drive system has both coarse (318 µm/rev, provided by the screw labeled B in the diagram to the right) and fine (25 µm/rev, provided by the screws labeled C and D in the diagram to the right) adjustment capability. The fine adjustment drive system uses two lead screws; one pushes the center spindle forward at 400 µm per revolution, and one pulls it back at 375 µm per revolution. The resulting total forward motion of the center spindle is just 25 µm per revolution, equating to 660 µrad per revolution for the KS1D and 400 µrad per revolution for the KS2D. The differential drive mechanism is actuated by inserting a hex wrench through the coarse adjuster knob (labeled A in the diagram) and turning the intermediate actuator embedded in the adjuster screw.

| Item # | Optic Diameter | Minimum Optic Thickness |

Coarse Angular Adjustment | Adjuster Thread |

Coarse Resolutiona | Resolution Using Differential Mechanisma | Minimum Incremental Movementb | Mounting Style | Angular Range with Differential Mechanism | Pitch and Yaw Differential Adjuster |

|---|---|---|---|---|---|---|---|---|---|---|

| KS1D | 1" or 25.0 mm |

0.16" (4.1 mm) |

±4º | 1/4"-80 / M3 x 0.40 / M3 x 0.375d |

8.3 mrad/rev | 660 µrad/rev (136 arcsec/rev) |

2.91 µrad (0.6 arcsec) |

#8 (M4) Counterbored Holes, 2 Places |

±1.5° | DAS110c |

| KS2D | 2" or 50.0 mm |

0.20" (5.1 mm) |

±4º | 1/4"-80 / M3 x 0.40 / M3 x 0.375d |

5.1 mrad/rev | 400 µrad/rev (82.5 arcsec/rev) |

1.45 µrad (0.3 arcsec) |

#8 (M4) Counterbored Holes, 6 Places |

±0.9° |

Click to Enlarge

KS3 Shown with a PIAK10 Piezoelectric Intertia Actuator

- Optics Secured in Double-Bored Hole with Nylon-Tipped Setscrew

- Thick Back Plate and Heavy-Duty Springs for Stability

- Fabricated from Black Anodized Aluminum

- Hardened Stainless Steel Inserts at Kinematic Contacts Reduce Wear

The KS3 and KS4 Precision Kinematic Mirror Mounts are designed to accommodate Ø3" (or Ø75 mm) and Ø4" (or Ø100 mm) optics, respectively, and provide ±4° of pitch and yaw adjustment. In addition to the increased mass of the mount, stiffer springs and hardened inserts at all contact points have been incorporated to enhance the overall performance.

These mounts incorporate two 1/4"-80 TPI, lockable adjusters and offer ±4º of angular adjustment. Stainless steel lead adjuster screws with brass bushings provide smooth adjustment. Four #8 (M4) counterbored mounting holes allow for post mounting in either left- or right-handed orientations.

| Item # | Optic Diameter | Minimum Optic Thickness | Optical Axis Height | Angular Adjustment | Number of Adjustersa | Type of Adjustersa | Adjuster Thread |

Mounting |

|---|---|---|---|---|---|---|---|---|

| KS3 | 3" or 75.0 mm |

0.28" (7.1 mm) |

2.13" (54.1 mm) |

±4º | 2 | Removable Knobs | 1/4"-80 | #8 (M4) Counterbored Holes, 4 Places |

| KS4 | 4" or 100.0 mm |

0.28" (7.1 mm) |

2.70" (69.0 mm) |

±4º | 2 | Removable Knobs | 1/4"-80 | #8 (M4) Counterbored Holes, 4 Places |

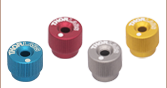

- For Convenient Adjustment of 5/64" and 2 mm Hex-Driven Actuators

- Red Anodized Adjustment Knob with Engraved Hex Size

- Replaceable Hex Tip

- Sold in Packages of 4

These 5/64" Hex Key Adjuster Thumbscrews allow for quick adjustment of many 5/64" and 2 mm hex-driven actuators (or standard actuators with the knobs removed). These temporary knobs can be left in the screw's hex socket between adjustments for convenience (see photo to the right). An 8-32 setscrew (5/64" hex) secures the replaceable hex bit, which can be reversed if the tip is stripped. Contact Tech Support to order replacement hex key bits.

We offer hex key thumbscrews in sizes from 0.050" to 3/16" and 2 mm to 5 mm.

Click to Enlarge

F25SSK1S has a small diameter and includes side holes for adjustment with a 5/64" (2.0 mm) hex key.

- Use with 1/4"-80 Adjusters

- Ø0.15" (Ø3.8 mm) Clearance Hole for Accessing the Adjuster with a Balldriver

- Six Ø0.09" (2.4 mm) Holes on the Sides of the Knob Compatible with a 5/64" (2.0 mm) Balldriver

- Ø0.35" (8.9 mm) Diameter Knob

Our F25SSK1S Low-Profile, Removable Adjustment Knobs thread onto our 1/4"-80 F25SS series hex adjusters, which can be found on many of our kinematic mounts, and allow for the use of an adjuster without a hex key. This provides quick and easy adjustments for a broad range of applications. In addition, these knobs feature six equally spaced actuation holes along the outer diameter of the knob that can be engaged with a 5/64" (2.0 mm) balldriver or hex key, as shown in the image to the right. The side holes provide the user with a method for more precise adjustments and allow the user an easier method of turning the knob when access to the knob is limited in an experimental setup. The small diameter (Ø0.35") of this knob also allows kinematic mounts, such as the KS1, to be attached directly to an optical table or breadboard, as shown in the image to the right.

Products Home

Products Home

Zoom

Zoom

Click to Enlarge

Click to Enlarge

Precision 2 and 3 Adjuster Kinematic Mirror Mounts

Precision 2 and 3 Adjuster Kinematic Mirror Mounts