Conductive Epoxy and Tape

- Conductive Silver Epoxy

- Thermally Conductive Double-Sided Tape

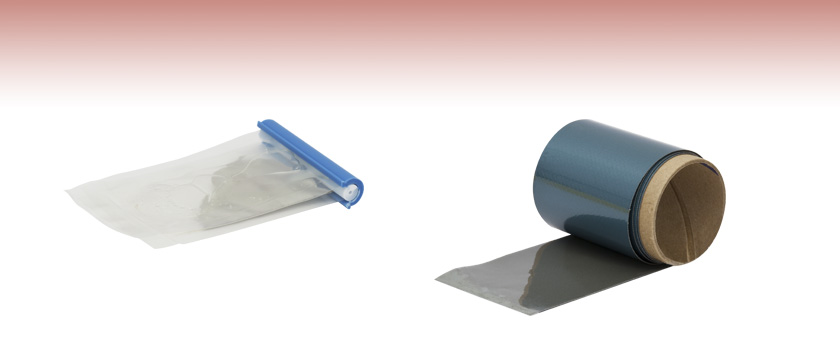

EG58

Silver Epoxy 4.4 g

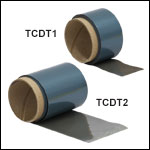

TCDT2

Please Wait

Thorlabs offers the Electrodag™ 5810 Conductive Epoxy and two sizes of Thermally Conductive Double-Sided Tape. Thorlabs also carries standard epoxies and adhesives.

| Posted Comments: | |

agerakis

(posted 2016-08-25 20:46:57.95) Is there any solvent that can be used to aid the removal of TCDT2? It has stuck on a copper piece and won't come off! bdada

(posted 2012-04-24 19:17:00.0) Response from Buki at Thorlabs to sebastien.avila:

Thank you for participating in our feedback forum. As the 5810 is silver filled, it should have a correspondingly high thermal conductivity. However, this value has not been tested by the manufacturer.

Due to the wide range of applications, temperatures, substrates, and environments in which this product can be used, we recommend first testing its fitness for use in your specific application.

We would be happy to provide you with a sample for testing. We have contacted you to provide further assistance. sebastien.avila

(posted 2012-04-23 12:03:47.0) Hello,

What is the thermal conductivity of the EG58 in W/mK? bdada

(posted 2012-03-15 14:01:00.0) Response from Buki at Thorlabs:

Thank you for your feedback. Unfortunately, we do not have the spectral absorption data. Please contact us at TechSupport@thorlabs.com if you want to discuss your application further to ensure this epoxy is suitable. user

(posted 2012-03-13 14:11:50.0) Is there spectral absorption data available for this product? |

- Ideal for Mounting Conductive Components that Cannot be Soldered

- Low Resistance Epoxy Coating or Adhesive, 0.0007 Ohm-cm

- Lap Shear: 1000 psi

- Maximum Operating Temperature of 250 °F (121 °C)

Thorlabs offers Electrodag™ 5810 Conductive Epoxy for use in places where soldering is not possible. This two-component epoxy has good electrical and thermal conductivity, featuring a low volume resistance of 0.0007 Ohm-cm and a lap shear of 1000 psi. The silver-filled epoxy has a cure time of 24 hours at room temperature; the cure time can be accelerated to 2 hours at 149 °F (65 °C) or 1 hour at 212 °F (100 °C). The epoxy is packaged in two separate bags with a net weight of 4.4 grams.

The shelf life of EG58 Epoxy will vary depending on the date the epoxy was packaged at the manufacturer. For information on the shelf life of EG58 Epoxy, please contact Tech Support.

- Thermally Conductive Double-Sided Acrylic Adhesive Tape

- 0.009" (0.229 mm) Thick

- Two Options:

- TCDT1: 1" Wide x 48" Long (25.4 mm x 1219 mm)

- TCDT2: 2" Wide x 24" Long (50.8 mm 610 mm)

- Great Alternative to Heat-Cured Adhesives, Screw Mounting, or Clip Mounting

- Provides a High Bond Strength to a Variety of Surfaces

- Can be Removed without Damaging Parts

The thermally conductive, double-sided tape consists of a superior bond strength, pressure-sensitive acrylic adhesive loaded with titanium diboride and applied to an expanded aluminum carrier. The tape is embossed with an innovative pattern for maximum conformability and minimal air pockets and offers excellent thermal, mechanical, environmental, and chemical properties. Our thermally conductive double-sided tape can bond heat sinks and thermal plates to components without the use of clips, screws, other mechanical fasteners, or additional thermal compounds and can be removed after the application without damage to the component.

| Item # | TCDT1 | TCDT2 |

|---|---|---|

| Construction | ||

| Carrier | Expanded Al | |

| Color | Grey | |

| Thickness | 0.009" ± 0.001" (0.229 mm ± 0.03 mm) | |

| Thermal | ||

| Thermal Impedance @ <1 psi | 0.25 °C-in2/W (1.7 °C-cm2/W) | |

| Thermal Conductivity | 1.40 W/m-K | |

| Electrical | ||

| Voltage Breakdown | NA | |

| Volume Resistivity | 0.013 ohm-cm | |

| Flammability Rating (E140244) | Not Rated | |

| Lap Shear Adhesion | 70 psi (0.483 MPa) | |

| Item # | TCDT1 | TCDT2 | |

|---|---|---|---|

| Mechanical | |||

| Die Shear Adhesion |

|||

| Aluminum | 135 psi (0.931 MPa) @ 25 °C 25 psi (0.172 MPa) @ 150 °C |

||

| Copper | 115 psi (0.793 MPa) @ 25 °C 35 psi (0.241 MPa) @ 150 °C |

||

| Aluminum Oxide | 125 psi (0.862 MPa) @ 25 °C 40 psi (0.276 MPa) @ 150 °C |

||

| Creep Adhesion |

|||

| 25°C, 12 psi (0.083 MPa) | >50 days | ||

| 150°C, 12 psi (0.083 MPa) | >50 days | ||

| Adhesive CTE, -40 to 150 °C | 400 ppm/°C | ||

| Dimensions | 1" x 48" (25.4 mm x 1219 mm) |

2" x 24" (50.8 mm x 610 mm) |

|

Products Home

Products Home

Zoom

Zoom

Conductive Coating and Adhesives

Conductive Coating and Adhesives