UV-Curing Optical Adhesives

- Adhesives for Glass to Metal, Glass to Glass, & Glass to Plastic

- Optic Adhesives with Low Shrinkage/Low Stress

- Block Adhesive for Temporary Bonding of Glass to Metal

NOA61

UV Curing Optical Adhesives

NBA107

UV Curing Block Adhesive

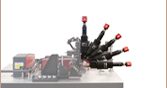

Nd:YAG Laser Line Mirror Attached to Polaris® Clear-Edge Mirror Mount Using Optical Adhesive

K6-NOA

Adhesive Kit

Please Wait

Features

- Low Shrinkage (1.5%) and Low Stress

- Strong Glass-Metal, Glass-Glass, and Glass-Plastic Bonds

- Recommended UV Curing Intensity >2 mW/cm2 @ 365 nm

- Dispenser Bottle Contains 1 oz (NOA Products) or 100 g (NBA107) of Adhesive

Norland Optic Adhesives are clear, one part adhesives that contain no solvents. When exposed to UV light, they gel in seconds and cure fully in minutes to give a tough resilient bond. Each of the six formulas listed below has been optimized to provide excellent bonding for specific applications. To cure these optical adhesives, they must be exposed to UV light.

Shelf Life

These UV-curing adhesives have a shelf life of approximately 8 months. This time frame begins on the date the epoxy was packaged at the manufacturer. Upon receipt by the end user, Thorlabs guarantees that the remaining shelf life will be at least 3 months.

| Item # | Adhesion | Item Description | ||||||

|---|---|---|---|---|---|---|---|---|

| NOA60 (Only Available in K6-NOA KIt) |

|

NOA60 typically has three uses: as a mounting cement for lenses, for the assembly of doublets or prisms, or for mounting components between two pieces of glass or plastic. Due to its excellent insulating properties, NOA60 can also be used as a protective overcoat on electrical components. The cured polymer has an refractive index of 1.56 Please note that the NOA60 is only available in the K6-NOA. Please click here to view the Material Safety Data Sheet (MSDS) for this item. |

||||||

| NOA61 |

|

NOA61 is designed to give the best possible bond to glass surfaces and may be polished after curing. It meets Federal Specification MIL-A-3920 for optical adhesives and is approved for use on all government contracts specifying such adhesives. This adhesive has excellent adhesion to metal, fiberglass and glass-filled plastics. The refractive index of the cured polymer typically has a value of 1.56. | ||||||

| NOA63 |

|

NOA63 can be used for bonding achromats, prisms and all other precision compound optics. The characteristics of this adhesive are its low fluorescence and its excellent transmission in the UV range. This adhesive is also suitable for bonding glass to metal. The adhesive cures well in thick sections and has a slight resiliency to minimize strain. The refractive index of the cured polymer typically has a value of 1.56. | ||||||

| NOA65 |

|

NOA65 when cured is a very flexible adhesive and minimizes strain. It is suitable where the adhesive cross section would be relatively thick. It has enough elasticity to minimize strain even when materials with different coefficients of expansion are bonded. It is used for potting of lenses in metal mounts and bonding plastic to glass. It is also a blocking cement for temporary mounting on polishing blocks. The refractive index of the cured polymer is 1.52. | ||||||

| NOA68 |

|

NOA68 is a flexible adhesive designed to give improved adhesion to many plastics such as acrylic, polycarbonate and CAB. Suggested uses for NOA68 include bonding compound plastic lenses, laminating polarized film between glass or plastic, mounting lenses in metal or plastic mounts and bonding cover glasses onto plastic optics. The refractive index of the cured polymer typically has a value of 1.54. | ||||||

| NOA81 |

|

NOA81 is an extremely fast curing adhesive. NOA81 has similar qualities to the NOA61, yet it can cure 3 to 5 times faster. However, curing times are dependent on the UV light source. Not only is it a faster curing adhesive, it is also tougher and stronger. NOA81 is recommended for applications that require extra toughness or speed in curing. The refractive index of the cured polymer typically has a value of 1.56. Like NOA61, it may also be polished. | ||||||

| K6-NOA | K6-NOA kit includes all six of the NOA UV curable optical adhesives above together with application data on each of the adhesives. The kit does not include the NBA107 block adhesive for temporary bonding of glass to metal. | |||||||

| NBA107 | NBA107 is a single component, UV curable adhesive used to temporarily bond optical components to metal polishing fixtures. The adhesive cures by exposure to UV light, thus eliminating the heat induced strain typically of hot pitch mounting methods. Deblocking, or removal of the optic is accomplished by immersing the bonded optic in warm (80 °C) water. The refractive index of the cured polymer typically has a value of 1.51. | |||||||

Common Specifications

- Cure: UV

- Color: Clear

- Linear Shrinkage: 1.5%

- Coefficient of Thermal Expansion at Room Temperature: 220 x 10-6 in/in-°C

| Item # | Recommended Uses | Adhesion | Viscosity @ 25 °C | na | Tensile Strength | Shore D Hardness |

Net Weightb |

||

|---|---|---|---|---|---|---|---|---|---|

| Glass | Metal | Plastic | |||||||

| NOA60c | Tough general purpose adhesive with excellent insulating properties |

Good | Good | Fair | 300 CPS | 1.56 | 2,800 psi | 81 | 1 ± 0.07 oz (28 ± 2 g) |

| NOA61 | Preferred optical adhesive, meets MIL-A-3920 | Excellent | Excellent | Fair | 300 CPS | 1.56 | 3,000 psi | 85 | |

| NOA63 | Bond components by curing a hard resilient, thick bead along an edge |

Good | Good | Fair | 2,000 CPS | 1.56 | 5,000 psi | 90 | |

| NOA65 | Flexible adhesive suitable for low strain applications and cold blocking |

Good | Good | Fair | 1,200 CPS | 1.52 | 1,500 psi | 50 | |

| NOA68 | Flexible bond, ideal for plastics such as polycarbonate, CAB and acrylic |

Excellent | Good | Good to Excellent |

5,000 CPS | 1.54 | 2,500 psi | 60 | |

| NOA81 | Fast curing adhesive for tacking, a hard resilient bond |

Excellent | Excellent | Fair | 300 CPS | 1.56 | 4,000 psi | 90 | |

| NBA107 | Temporary bonding of optics to metal | Fair | Excellent | Fair | 350 CPS | 1.51 | - | - | 100 g |

Optical Properties

Using the Cauchy Equation below one can calculate the refractive index (n) at a specific wavelength (λ) for the NOA and NBA Series optical adhesives.

Where n25 °C = Refractive Index at 25 °C for a specific wavelength (nm), and A, B and C are constants determined by the material.

For the NOA61, NOA63 and NOA81 adhesives:

A = 1.5375

B = 8290.45

C = -2.11046 x 108

For the NOA65 and NBA107 adhesives:

A = 1.50631

B = 5435.62

C = 2.77798 x 107

Note: We are currently gathering more information on the optical properties of the NOA series adhesives and will post it as soon as it is available.

| Posted Comments: | |

Ben Cotts

(posted 2021-01-15 16:45:11.577) Are NOA61 or NOA81 best for Sapphire-Metal bonding? user

(posted 2020-12-02 08:11:55.157) Please could you provide any information on the contact angle to water of NOA81. llamb

(posted 2020-12-09 03:28:36.0) Thank you for contacting Thorlabs. We do not have formal test data on any NOA adhesives' contact angle, though I will reach out to you directly with some third party papers that discuss contact angle of NOA81. 云坤 王

(posted 2020-11-23 16:40:15.677) 请问这些胶固化后怎么去除?我们用来粘合玻璃和PDMS,用完后希望把PDMS揭下来并且不希望在玻璃上留下残留。How to remove these adhesives after curing? We use it to glue glass with PDMS. We want to remove PDMS after use and do not want to leave any residue on the glass. llamb

(posted 2020-11-24 01:32:17.0) Thank you for your feedback. I will reach out to you directly with a document discussing separating lenses bonded with our NOA- adhesives. In short, the simplest method is to immerse the lens overnight in a solvent combination made up of the following: 100 parts by weight methylene chloride, 15 parts methanol, 2 parts concentrated ammonia (26

Baumé or 29% NH ). Rick Metzbower

(posted 2020-10-30 11:24:15.167) What is the density of NOA68? YLohia

(posted 2020-10-30 11:35:22.0) Hello Rick, the liquid density is 1.231 gm/cc while the cured density is 1.29 gm/cc. bouchez guillaume

(posted 2020-10-22 03:58:35.34) hello

I'd like used NOA63 for making cube. Have you a curve of transmittance for this product, i'm interrested to this for the range 260-1000nm.

Thank you for you reply., YLohia

(posted 2020-10-26 04:42:15.0) Hello, thank you for contacting Thorlabs. Please see the transmission curve for the NOA63 on Norland's website here: https://www.norlandprod.com/adhesives/NOA%2063.html. user

(posted 2020-10-15 15:03:21.66) Hello, we will use NOA61 for gluing optics onto mounts, would it possible in some way to remove glued optical element from the mount? YLohia

(posted 2020-10-15 11:34:05.0) Hello, thank you for contacting Thorlabs. The simplest method for separating a lens bonded with Norland Optical Adhesive is to immerse the lens in a solvent combination made up of the following: methylene chloride, 100 parts by weight ‐methanol, 15 parts ‐ concentrated ammonia (26 Baumé or 29% NH ), 2 parts. A typical 1" diameter lens will separate easily before the full cure by an overnight soak in these solvents. A fully cured lens requires a longer soak because the adhesive is more crosslinked and slows the solvent penetrations. To separate some lenses, a slight thermoshock is necessary. Warm the lens up to 150°F and immerse it in the solvent combination while still warm. An alternate heating method is to place lenses in a vacuum coater and heating them under vacuum until they separate. Then you can remove adhesive from glass surfaces by immersing in the solvent combination. Protective goggles and gloves should be used when handling these chemicals. Philip Ekstrom

(posted 2020-09-16 04:51:26.943) What is it that changes about NOA68 when it is too old to use, that you can notice to tell you not to use it? llamb

(posted 2020-09-17 03:32:27.0) Thank you for contacting Thorlabs. When these adhesives are past their shelf life or expired, they will increase in viscosity and get thicker. So outside of following the manufacturing date and shelf life, there would be some user judgement. peiran yin

(posted 2020-09-02 10:58:37.35) what's the density of NBA 107?

Thanks YLohia

(posted 2020-09-02 11:55:05.0) Hello Peiran, thank you for contacting Thorlabs. The liquid density is 1.231 gm/cc while the cured density is 1.29 gm/cc. Philip Ekstrom

(posted 2020-09-01 13:41:17.96) What is the volume resistivity of NOA68?

Thanks

phil.ekstrom@nmt.us YLohia

(posted 2020-09-02 11:28:20.0) Hello Phil, thank you for contacting Thorlabs. The volume resistivity of the NOA68 is 10^15 Ohms-cm. Wenpeng Liu

(posted 2020-07-26 16:21:54.093) Hi,

I hope this email finds you well. This is Wenpeng Liu from Harvard Medical School. We are currently doing research that relates to nanofabrication, and notice that Norland Optical Adhesive 61 (NOA 61) is a great candidate for the nano-imprinting.

Would you like to send me some free samples of Norland Optical Adhesive 61 (NOA 61) for test?

I appreciate your support and look forward to hearing from you.

Thank you.

Wenpeng with best regards YLohia

(posted 2020-07-27 10:23:40.0) Hello Wenpeng, thank you for contacting Thorlabs. We will reach out to you directly to discuss your request further. Jerzy Dolinski

(posted 2020-02-12 05:02:01.9) Hi, is NOA61 suitable for bonding the High-Power Polarizing Beamsplitter Cube to aluminium holder? Could you please recommend other adhesives? llamb

(posted 2020-02-12 05:24:15.0) Thank you for contacting Thorlabs. Yes, NOA61 will have excellent bond strength between a beamsplitter cube and an aluminum holder, and between glass and metals in general. You can also consider NOA81 for a faster curing time with similar strength, or otherwise our general adhesives linked in our Related Items column above. Alexandre Braga

(posted 2020-01-23 14:31:55.43) Hi,

Do you have instructions on how to use (cure) NOA61? YLohia

(posted 2020-01-23 03:54:24.0) Hello, thank you for contacting Thorlabs. The NOA61 is cured by ultraviolet light with maximum absorption within the range of 320-380 nm with peak sensitivity around 365nm. Typically for optical applications, a precure is used first. The precure time is of sufficient duration to set the bond and allow it to be moved without disturbing alignment. This is followed by a longer cure under UV light to obtain full cross linking and solvent resistance of the adhesive. For the precure, you may use the CS2010 at a low intensity setting for up to a minute. The final cure can be accomplished within a few minutes using our CS2010 curing system at full intensity. Please note that actual curing times change from application-to-application due to varying amounts of adhesives used, power density of the source, and materials being bonded. Mohamed Mohamed

(posted 2020-01-14 11:59:04.38) Can you please provide me with the absorption spectrum of NOA61, starting from a wavelength of 200 nm? YLohia

(posted 2020-01-14 12:05:05.0) Thank you for contacting Thorlabs. I have reached out to you directly with the transmission data for the NOA61 that we have. Takagi Daisuke

(posted 2019-10-10 17:38:58.82) Please tell us about the moisture-proof performance of NOA61 after bonding. asundararaj

(posted 2019-10-11 04:44:38.0) Thank you for contacting Thorlabs. NOA61 is specified to have a 0.16% water absorption after curing. I have reached out to you directly to discuss this further. SIAR VILK

(posted 2019-09-30 08:40:23.67) Good day! We have a problem - can't find quality optically clear adhesive for bonding scintillators (glass) and optical fibers (plastic, PMMA), or a scintillator (crystal) + fiber (plastic, PMMA) + photomultiplier tube (glass). Which of your materials can you recommend? Do I need a sublayer for good adhesion? How is this material applied and how is it polymerized? These adhesives are repairable? Thank you! nbayconich

(posted 2019-10-03 08:26:36.0) Thank you for contacting Thorlabs. One possible solution is to use the NOA68 however the NOA86 provided by Norland would be the best option in terms of bonding plastic fiber to glass substrates, this isn't readily available on our website but can be purchased through Norland directly.

No sublayer would be needed and the adhesive can be removed with acetone if it is still in liquid form. Once cured removal is more difficult but possible, I'll reach out to you with more information about adhesive removal.

In terms of the NOA86 and NOA68 curing properties, NOA86 is formulated to bond fiber and is able to withstand exposure to 85C/85%Relative Humidity, the NOA68 will not. NOA86 is oxygen inhibited so it would need to be cured under a nitrogen atmosphere if exposed to air, the NOA68 is not oxygen inhibited. Yuki Nishio

(posted 2019-09-17 11:28:43.463) Hello. According to your website, NOA61 works well with metal and glass.

I'd like to glue a cupper or an aluminium plate onto a glass slide by NOA61.

Let me know with which metal it works well. YLohia

(posted 2019-09-17 12:48:16.0) Hello, thank you for contacting Thorlabs. The NOA61 will adhere to either metal equally well. Please be sure to expose all the adhesive to the UV light at the same time. If the glass is recessed into a metal holder, there is the possibility that shadowing may occur and cause stress to build up in the bond line. TAKAGI Daisuke

(posted 2019-09-03 16:54:43.48) I want to know glass transition temperature (Tg) of "NOA61". YLohia

(posted 2019-09-03 04:55:01.0) Hello, thank you for contacting Thorlabs. Tg for the NOA61 is 30 C.

CTE = 220 x 10-6 inches/inches/C.

This adhesive is made from a urethane related base material and behaves differently than epoxies and acrylates. It is more flexible and resilient, which makes it better able to handle the stress created by bonding substrates with different CTEs. The adhesive becomes a little bit softer above Tg. Kosuke Mizuno

(posted 2019-07-25 17:41:08.613) Hello, please let me know the resistance for organic solvent, especially acetone, methanol, ethanol, and xylene. llamb

(posted 2019-07-25 06:06:46.0) Thank you for contacting Thorlabs. I have reached out to you directly to discuss the chemical resistance of our Norland Optical Adhesives. user

(posted 2019-06-21 14:51:21.367) Hello. Is there a minimum thickness for NOA61? I'm trying to find an adhesive that will give me a bonding layer of about 1 µm. Is that possible with this product? llamb

(posted 2019-06-25 01:29:57.0) Thank you for your feedback. Typical applications use a thickness of 1 to 50 mils (~25 µm to ~1 mm) as an adhesive layer. A thinner bond line will mean less bond strength, though a micron thickness has been successfully done before. I have reached out to you directly to discuss your application's needs further. simone.i.rupp

(posted 2019-02-20 13:50:44.967) Hello, I wonder at which maximum temperature I can use components bonded by NOA63 after it has been cured via UV.

In the data sheet I find a storage temperature (5-25°C), flash point (175°C) and decomposition temperature (> 300°C), but I assume those are valid for the not yet cured product, especially the storage and flash point temperature. (Or is there a risk of setting fire to the cured adhesive over 175°C?)

Thanks in advance. llamb

(posted 2019-02-20 01:35:33.0) Thank you for your feedback. NOA63 has an operating temperature range from -15 to 60° C when used to bond glass optics, after having been cured. Temperatures to 90° C are possible when the adhesive is used as a thin film or coating, but this will depend on the application. I have reached out to you by email to discuss your application further. bsaxe011

(posted 2018-02-11 11:57:21.957) Hello,

Is there a way to order several bottles of NOA61 with a specific LOT number? For example, if you zoom in on the image, the product has a LOT number 289 written right beside the number 61.

If so, we would like to buy a couple of NOA61 adhesives with LOT number 366.

Thanks in advance. llamb

(posted 2018-02-16 11:08:53.0) Hello, thank you for contacting Thorlabs. We can offer bottles of optical adhesive with a specific lot number, though it will depend on what we have in stock at the time, as well as the desired quantities. I will reach out to you directly to discuss this further. user

(posted 2018-01-26 15:11:52.173) Hi, I would like to glue two plastic optical fibre 1 mm diameter, which product do you recommend? tfrisch

(posted 2018-01-26 01:12:59.0) Hello, thank you for contacting Thorlabs. I would not recommend using optically clear adhesive as a form of splicing plastic fibers. It may be that you could still use index matching gel to avoid air between fibers, but I would need to know what the index of refraction of the plastic is. Please reach out to us at TechSupport@Thorlabs.com to discuss the details of your fibers. jumu3095

(posted 2017-11-09 15:53:07.553) Hi,

I am looking into gluing a waveplate (zero order quartz crystal) to a mirror (BB1-E02). I am interested in keeping high transmission and not induce significant birrefringence. I am looking into the NOA61, do you have any other recommendation?

Thanks!

Juan tfrisch

(posted 2017-11-15 05:16:09.0) Hello, thank you for contacting Thorlabs. Both the mirror coating and the waveplate's AR coating would be designed for glass-air interface, so putting them each in contact with another layer might adversely affect both coatings. I could instead recommend keeping an air gap as surface losses will be small if the waveplate is used near its design wavelength. I will reach out to you directly to discuss your needs. svasile

(posted 2016-11-10 14:46:03.19) For NOA61 please specify the units of measure for lambda in the optical properties tab (in the Cauchy formula). Also please provide a link to Norland for the curing schedule (this link worked for me https://www.norlandprod.com/adhesives/noa%2061.html). tfrisch

(posted 2016-11-10 04:10:28.0) Hello, thank you for contacting Thorlabs. The units for wavelength are nm. If you have any questions about these Norland adhesives, our Tech Support team (TechSupport@Thorlabs.com) would be the best point of contact. rahul.kumar

(posted 2016-08-05 19:28:28.18) Excellent collection of UV curable glues. can you tell me the thermo-optic coefficient for these adhesives? which i need for accurate analysis for one of my experiments. achmyro

(posted 2015-06-17 13:45:03.207) If we will use NOA65 for gluing optics into kinematic mounts, would it possible in some way to remove this optical element from the mount? By heating/other treatment? Or will it stay bound forever?

Would this removal process require strong force, i.e. is it possible to glue a thin 1 mm dichroic mirror and remove it later intact, if needed? besembeson

(posted 2015-09-21 04:45:10.0) Response from Bweh at Thorlabs USA: Depending on the amount of surface area epoxied and how long they have been bonded, it may not be possible to separate these. You can try soaking the parts in either methylene chloride or xylene bath for as long as necessary. Note that these solvents are hazardous so all proper safety precautions must be followed when using these chemicals. nazmul.eng

(posted 2015-04-01 18:07:21.18) Whats the Cauchy coefficients for NOA68? And how much thickness it will be after spin coated? Do you have spin coat vs thickness curve? cdaly

(posted 2015-04-15 03:33:28.0) Response from Chris at Thorlabs: I'm afraid we do not have any values for the Cauchy coefficients. The only data we have for the refractive index of NOA68 is the specification from Norland Optics which is typically 1.54 for the cured polymer. Unfortunately, we do not have any specifications in terms of the spin coating-thickness dependence either. yuns.jeon

(posted 2014-12-04 14:29:53.8) Regarding NOA61,I'm considering to purchase a CS2010. But, I'm concerning that the optical output power of CS2010 is compatible to NOA61. I can see that the recommended power is 2 mW. Could you confirm it compatibility or give any kind of instruction in using NOA61 with CS2010. Thanks. jlow

(posted 2014-12-11 11:24:45.0) Response from Jeremy at Thorlabs: The recommended UV-curing intensity is >2mW/cm^2, which the CS2010 can provide easily. The actual intensity from the CS2010 will depend on the attachment you put in front and the current setting from the driver. One should also look at the application (e.g. size of components, cure time requirement) to determine the suitability of the CS2010. I will contact you directly to discuss more about this. ladislav.chytka

(posted 2014-09-26 14:23:34.453) In description of NOA63, you specify "excellent transmission in the UV range". We are considering using it for gluing a light guide for 200-400 nm. Could you provide us transmittance values for this region?

Also, do you have some glue, that would be cured by light with wavelength outside the 200-400 nm interval? I suspect a transmittance drop near 365 nm as it is the curing wavelenght. jlow

(posted 2014-09-29 03:18:45.0) Response from Jeremy at Thorlabs: The NOA63 transmission falls off quickly after 365nm. At 320nm, it has around 80% transmission. yinghsiulin

(posted 2014-09-04 10:37:11.063) Could we heat the cured adhesive (such as NOA61) to higher than 60 degree Celsius for 2 hours? What is the limited temperature of cured adhesive? Thanks. jlow

(posted 2014-09-04 08:24:54.0) Response from Jeremy at Thorlabs: You can heat the cured adhesive to 60°C. I will send you a graph directly for the service temperature with the coefficient of thermal expansion. guguoqiang2009

(posted 2013-11-28 19:40:28.573) Dear technical engineer,

I want to know the thermal expansion coefficient of NOA 61. jlow

(posted 2013-12-04 01:40:23.0) Response from Jeremy at Thorlabs: You can find the CTE for NOA61 at https://www.norlandprod.com/adhesives/noa61pg2.html. marcus.nowatzki

(posted 2013-06-03 15:01:45.65) I have a question to the product NOA61: The adhesive hardered only with the UV light or also without the uv-light but very slower?

Thank you for helping. jlow

(posted 2013-06-04 10:20:00.0) Response from Jeremy at Thorlabs: The NOA61 epoxy must be cured by UV-light. marcus.nowatzki

(posted 2013-06-03 14:53:33.467) 1st: I need technical datasheed for adhesive NOA61. Where can i get that.

2nd: The UV Curing system has only a US-power cable, maybe it was better to put an German power cable in the box, when it was delivered in Germany. jlow

(posted 2013-06-04 10:22:00.0) Response from Jeremy at Thorlabs: You can find the datasheet at http://www.thorlabs.com/Thorcat/0900/NOA61-SpecSheet.pdf. The CS2010 curing system should have come with a German power cable for you. I will get in contact with you directly to send you a German power cable. jlow

(posted 2012-10-24 13:41:00.0) Response from Jeremy at Thorlabs: The typical thickness for the adhesive is on the micron level, from 50-200µm. ali.eichenberger

(posted 2012-10-24 08:20:32.893) I plan to use NOA61 or NOA81 to bound a titanium piece on a glass rod (4 mm diam). Is there a typical thikness of glue I need to use? or thiner is better? Thorlabs

(posted 2010-12-02 09:55:13.0) Response from Javier at Thorlabs to tang.ep90g: we do not carry the NOA68T adhesive, but me may be able to offer it as a special item for you. I will contact you directly to start the quotation process. tang.ep90g

(posted 2010-12-02 15:47:32.0) Do you have NOA68T which is the same series of NOA68? Thorlabs

(posted 2010-11-08 12:33:22.0) Response from Javier at Thorlabs to Johannes: We would suggest using the NOA81 or NOA61 if the assembly needs to be polished after the curing process. These cure to the hardest surfaces. I will contact you directly to discuss your requirements regarding temperature dispersion. johannes.trapp

(posted 2010-11-08 14:49:45.0) Do you have information about the temperature dispersion of the adhesives?

And which ones can be polished after curing? john.arkwright

(posted 2010-09-28 07:50:01.0) Hi there

Do any of your Norlond optical adhesives, and NOA65 in particular, have approval for medical applications?

Thanks

John Arkwright apalmentieri

(posted 2010-01-05 12:04:14.0) A response from Adam at Thorlabs: In response to my earlier post, we have updated the website with an optical properties tab that includes the Cauchy Equation with Cauchy coefficients. apalmentieri

(posted 2010-01-04 09:02:39.0) A response from Adam at Thorlabs: We currently only have dispersion data for the NOA65. The refractive index of NOA65 is 1.5487(365nm), 1.5249(546nm), 1.52005(632.8nm), 1.51299(905nm), and 1.51112(1064.8nm). I am gathering data on the other epoxies and will post more information as soon as we have it. I will also work with our technical marketing team to get this data on the website. user

(posted 2010-01-03 13:31:46.0) It would be nice to have data on the index of refraction as a function of wavelength, can you please post the Sellmeier coefficients for these epoxies. If the coefficients are not avialable please provide a few data points (index & wavelength) from which we can estimate the optical disperson. jens

(posted 2009-05-15 15:09:20.0) A response from Jens at Thorlabs: The refractive index for the cured NOA61, NOA63, NOA81 polymer , is 1.56, NOA65 is 1.524, NOA68 is 1.54, NBA107 is 1.51. These are typical values as provided by Norland Products Inc. If you need additional data over a wavelenght range please let me know. Thanks jeffrey.owen.white

(posted 2009-05-15 14:49:52.0) What is the index of refraction of the various Norland adhesives? technicalmarketing

(posted 2007-10-24 11:33:01.0) In response to the last post, we have double checked and yes, the bottle has a net weight of 1 oz., so there is 28 g of adhesive in each bottle. jschumacher

(posted 2007-10-24 10:39:32.0) How much adhesive is in each bottle? It is a 1 ounce bottle but does it also include 28gram of adhesive? |

Products Home

Products Home

UV Curing Adhesives

UV Curing Adhesives