Aluminum Breadboards: High Stiffness, 25 mm (0.98") Thick

- Aluminum Plates and Core Minimize Thermal Instabilities

- High Strength-to-Weight Ratio

- Non-Magnetic Material

- Breadboards with Rail-Compatible Sides Available

PBG1212F

12" x 12" UltraLight™ Optical Breadboard

See BB Selection Guide Tab

T-Slot for 25 mm Rail Compatibility

Please Wait

| General Specificationsa | ||

|---|---|---|

| Breadboard Thickness | 25 mm (0.98") | |

| Top Skin Flatness | ±0.15 mm (±0.006") Over Any 0.3 m2 | |

| Construction | Double-Plate, Single-Honeycomb Core, Athermalized Aluminum Design |

|

| Top Plate | 6 mm Thick Aluminum | |

| Bottom Plate | 3 mm Thick Aluminum | |

| Core | High-Density Plated Aluminum Honeycomb | |

| Finish | Matte Black Paint | |

| Maximum Screw Depth | 6 mm (0.24") from Top Surface | |

| Breadboard Mounting | 1/4"-20 (M6) Taps on Bottom Plate | |

Features

- Thickness: 25 mm (0.98")

- Sides with Smooth Finish (Imperial) or T-Slot (Imperial or Metric) for 25 mm Rail Compatibility

- Lighter than Equivalent Surface Area Solid Aluminum Surface Plates

- All-Aluminum Plates and Core for Matching CTE to Reduce Thermal Effects

- Large Range of Sizes (W x L):

- Imperial: 1' x 1' to 3' x 4'

- Metric: 300 mm x 300 mm to 900 mm x 1500 mm

- More Rigid than 0.5" Thick Solid Aluminum Breadboards (See Construction Tab for Details)

- Matte Black Painted Surface Reduces Reflectivity and Backscatter

- High-Density Honeycomb Core Provides Static and Dynamic Rigidity

- Custom Sizes Available; Contact Tech Support for Details

Click to Enlarge

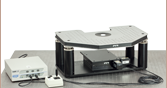

An optical enclosure can be constructed and attached to the side of a 25 mm rail compatible breadboard for easy placement of the enclosure. Please note this application requires the use of drop-in T-Nuts and standard 8-32 cap screws for attaching the hinges to the breadboard.

Click for Details

Click for DetailsThe T-Slot located on the sides is compatible with our 25 mm rails and accessories.

Thorlabs' UltraLight™ Honeycomb Breadboards offer a high strength-to-weight ratio and all-aluminum plates and core. Due to this construction, each breadboard has similar coefficients of thermal expansion throughout, which minimizes thermal instabilities. These breadboards are ideal for optical setups where portability and dynamic rigidity are important. They are typically used as replacements for aluminum, steel, or granite surface plates, as well as for applications demanding a totally nonmagnetic surface. Additionally, breadboards ending in "F" or "A" feature a t-slot that is compatible with our 25 mm rails and accessories. This allows for construction of rail systems or optical enclosures without the loss of taps. These breadboards also have plastic covers on the corners; two have labels with either the item number or serial number.

Choosing an Optical Breadboard

When choosing an aluminum optical breadboard, stiffness is a major consideration. For aluminum optical breadboards, Thorlabs offers two levels of stiffness: high and enhanced. Although most people associate deflection under load with thickness, it is actually the stiffness of a board that determines the deflection.

The higher the stiffness, the better the breadboard's ability to resist bending when a load or force is applied to it. Therefore, when a heavy load is placed in the center of a breadboard with high stiffness, the board will deflect more than it would if the same load were placed on an enhanced stiffness breadboard. This deflection can create misalignment between two components on opposite ends of the breadboard. This is especially important, for example, when conducting experiments that require sliding optical setups across the breadboard while maintaining a straight optical axis.

We also offer a broad selection of Nexus® Steel Honeycomb Breadboards, which provide greater stiffness and vibration damping. For a quick comparison of our different breadboard options, please see the BB Selection Guide tab.

Frame and Isolation Options

We offer a number of support options for breadboards. Our standard breadboard frames are available with rigid supports, or with passive or self-leveling active vibration isolation. We also offer passive and electronic isolator feet for mounting a breadboard on top of a table.

Click to Enlarge

Construction Features

Ultralight™ Honeycomb Aluminum Breadboard Construction

Thorlabs UltraLight™ optical breadboards offer high strength-to-weight ratio and excellent thermal stability. These breadboards are ideal for optical setups where portability and dynamic rigidity are important. Breadboards with item numbers that do not have a letter at the end feature standard aluminum side panels, while those with item numbers ending in F or A feature t-slots with compatiblity with our 25 mm rails and their accessories.

As shown in the diagram to the right, these breadboards incorporate a double-plate, single-honeycomb design, providing excellent stiffness and dynamic rigidity (see test performed below). The top layer consists of a 6 mm aluminum top plate. The second layer adds the main aluminum honeycomb structure and the 3 mm aluminum bottom plate. The main honeycomb core is fabricated from strips of precision-formed plated aluminum, which is bonded together with a high tensile strength epoxy adhesive. This all-aluminum construction minimizes thermal bowing effects caused by temperature variations.

Excellent Surface Flatness

Breadboard flatness is critically important during many experimental setups. Lack of local flatness requires readjustment of components for height variations across the breadboard and can cause component “wobble”. Thorlabs breadboards offer an unsurpassed flatness of ±0.15 mm (±0.006") over any 0.3 m2 area due to the high-precision aluminum plates which are specially handled to maintain superior flatness throughout the manufacturing process. A unique thermal bonding process ensures that stress is not induced during manufacture, thereby retaining the flatness of the top plate.

Stiffness Comparison Testing: Honeycomb Aluminum Breadboards vs. Solid Aluminum Breadboards

Figure 2: Plot Showing the Overall Displacement of the PBG60120A and MB60120/M After a Uniform Force was Applied to the Center of the Breadboard (See Diagram to the Left)

Purpose: Show that an UltraLight PBG60120A breadboard measuring 600 mm x 1200 mm x 25 mm with an unpackaged mass of 20.3 kg has a greater stiffness then the equivalent size MB60120/M solid aluminum breadboard that is 0.5" thick and has an unpackaged mass of 23.49 kg.

Procedure: As shown in Figure 1 below, each table was supported by fulcrum points that were spaced 1 m apart. Then, various loads were applied uniformly across the center of the breadboard and the amount of deflection was measured. From the data collected, a plot of Force vs. Displacement was created as shown to the right.

Figure 1: Both breadboards were reinforced at two defined fulcrum points. A uniform

force was then applied to the center of each board and deflection measured.

Results: The result shown in figure 2 shows that the PBG60120A honeycomb aluminum breadboard, which is 14% lighter than the MB60120/M solid aluminum breadboard, is 4.1 times stiffer. This can be found by dividing the two stiffness values, 1.44 x 106 and 3.49 x 105.

Conclusions: As can be seen in Figure 2, it is clear that the PBG60120A UltraLight honeycomb aluminum breadboards, though lighter by 3.19 kg, have a greater stiffness than the MB60120/M 0.5" thick solid aluminum breadboards. Therefore, our UltraLight series of breadboards is an excellent choice if you are looking for a light-weight breadboard with extremely good rigidity.

| Posted Comments: | |

hammons3

(posted 2018-05-15 16:51:15.457) Hello,

I would like to know if it is possible to safely drill a 1/4 inch hole through the top and bottom of the breadboard. the hole would be through an existing location of a tapped hole that is already there.

thanks,

josh bhallewell

(posted 2018-05-31 12:10:40.0) Response from Ben at Thorlabs: Thank you for your question. We would advise against drilling through a PBG* breadboard as there is no guarantee of where the Aluminium Core is located with respect to the hole. If you contact the core with your tooling, this could likely cause damage to the breadboard & your tooling. We can supply a new special breadboard with the hole already in place surrounded by a liner. Please contact your local Tech Support team for further details of Custom Breadboard capabilities & pricing. tomasz.giela

(posted 2018-02-20 15:24:18.357) Is there a possibility to have some through holes made in the breadboard of this kind? I am trying to design simple way to mount the breadboad to custom aluminum frame. I will be glad for help. bwood

(posted 2018-02-28 06:08:04.0) Response from Ben at Thorlabs: Thank you for your feedback. We have many different custom options for our tables and breadboards, including through holes, available. I will be in contact with you directly to gather more information on your requirements. peter.rossoni-1

(posted 2016-03-03 17:18:14.31) I'm interested in calculating modal frequencies of our breadboard, in our custom mounting arrangement. How can I get the exact dimensions of the facesheets and honeycomb core specs? user

(posted 2016-02-09 01:24:12.523) What is the difference in packaged and unpackaged mass? jlow

(posted 2016-02-15 10:01:19.0) Response from Jeremy at Thorlabs: The unpackaged weight is just the weight of the breadboard. The packaged weight includes both the breadboard and the shipping packaging. songxindong

(posted 2015-11-30 15:33:17.19) Hi Thorlabs,

I have previously bought a PBG11118 and a PBG11107. I recently want to buy a PBG11111. However, I found out the distances between back mounting holes are not aligned in inch multiples. Is there any possibilities that I can customize a PBG11111 with back holes intervals as 40" and 24", rather than 40.9" and 23.2"? Thank you.

Best,

Xindong besembeson

(posted 2015-12-03 01:09:55.0) Response from Bweh at Thorlabs USA: Yes this customization is possible. With the current version, you can also use similar 1.5" posts with a base such as the PB4 and clamping fork such as the PF175. I will contact for quotation if you still prefer the integer separation. muellenbroich

(posted 2014-02-03 14:46:39.563) I also need to cut out a section in the centre of the board and additionally need two holes to allow periscopes to get through. Can you help making custom sized holes in standard sized breadboards? msoulby

(posted 2014-02-04 07:16:52.0) Response from Mike at Thorlabs: We will contact you directly to discuss you custom breadboard requirements. ian.hill

(posted 2013-06-25 14:08:24.45) If I were to cutout sections of the board would the honeycomb structure remain sufficiently intact to form a suitable edge and not fatally compromise the board? jlow

(posted 2013-06-26 08:40:00.0) Response from Jeremy at Thorlabs: This depends on how the cut is made and the shape/location of the cut. Modifications like this are best done during production instead of post-production. We will get in contact with your to discuss about your application. jjurado

(posted 2011-07-18 13:59:00.0) Response from Javier at Thorlabs to coopb: You can certainly drill additional holes as needed into the bottom of the breadboard. However, care must be exercised so as not to damage the internal honeycomb structure. coopb

(posted 2011-07-15 08:37:01.0) Can I drill and tap additional mounting holes into the bottom of the board? Im using vibration isolating feet and need more than four to carry the load Im putting on the board.

Thanks,

Brian Adam

(posted 2010-04-09 12:11:58.0) A response from Adam at Thorlabs to Karl: I will contact you direct to find out how far off the hole locations are on your board. The holes drilled on the top of the breadboard have a tolerance of +/- .004". The holes on the bottom of the breadboard are drilled by hand and have a larger tolerance, +/-.04". karl.vandyk

(posted 2010-04-08 17:41:36.0) I just received the order TS0551689. I am trying to install the plates and I have found that the holes on the underside are not very accurate to the edge reference. I have two of these plates mounted side by side and the 1/4-20 holes on the top do not line up from one breadboard to the other. What is your tolerance on teh location holes on the underside?

Thanks

Karl van Dyk

Engineer

SRI international |

| Breadboards |  Nexus, Optimized Damping |

Intrinsically Damped |

Aluminum Honeycomb |

Stainless Steel |

Solid Aluminum |

Optically Clear Acrylic |

|---|---|---|---|---|---|---|

| Construction | ||||||

| Breadboard Thickness | 60 mm (2.4") 110 mm (4.3") |

58 mm (2.28") | 25 mm (0.98") 55 mm (2.2") |

12.7 mm (0.5") | 7.0 mm (0.28") 9.5 mm (0.375") 12.7 mm (0.5") 19.05 mm (0.75") |

12.7 mm (0.5") |

| Working Surface | 430 Grade Stainless Steel or 304L Grade Nonmagnetic Steel Top Plate | 430 Grade Stainless Steel Top Plate | Aluminum | 416 Grade Stainless Steel | Solid Aluminum Anodized or Unanodized |

Acrylic |

| Top Skin | 5 mm (0.20") | 5 mm (0.20") | 6 mm (0.24") | N/A | N/A | N/A |

| Bottom Skin | 5 mm (0.20") | 3 mm (0.12") | 3 mm (0.12") | N/A | N/A | N/A |

| Core Design | High-Density Plated Steel Honeycomb, 0.26 mm Thick | High-Density Plated Aluminum Honeycomb | N/A | N/A | N/A | |

| Side Panels | Rigid Steel Box Section | Unplasticized Polyvinyl Chloride (uPVC) | Black Laminated Aluminum Sides |

N/A | N/A | N/A |

| Ferromagnetism | Magnetic or Non-Magnetic Options | Magnetic | Non-Magnetic | Magnetic | Non-Magnetic | |

| Sealed Holes | Sealed (25 mm Depth) or Non-Sealed Options | Non-Sealed | N/A | N/A | N/A | |

| Thread Options | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6), 4-40 (M3), or 8-32 (M3) and 1/4"-20 (M6) Tapped Holes |

1/4-20" Tapped Holes | |

| Spacing | 1" (25 mm) Centers | 1" (25 mm) Centers | 1" (25 mm) Centers | 1" (25 mm) Centers or 0.5" (12.7 mm) Centers |

0.5" (12.7 mm) Centers | |

| Distance from Edge to First Holes |

0.5" (12.5 mm) on all Sides | 0.5" (12.5 mm) or 1.0" (25 mm) on all Sides |

0.5" (12.5 mm) on all Sides | 0.5" (12.5 mm) on all Sides | 1.0" (25.4 mm) on all Sides | |

| Performancea | ||||||

| Damping |  |

|

|

N/A | N/A | N/A |

| Stiffness |  60 mm (2.4") Thick |

58 mm (2.28") Thick |

25 mm (0.98") Thick |

12.7 mm (0.5") Thick 12.7 mm (0.5") Thick |

7.0 mm (0.28") Thick |

12.7 mm (0.5") Thick |

110 mm (4.3") Thick |

55 mm (2.2") Thick |

19.05 mm (0.75") Thick 19.05 mm (0.75") Thick |

||||

Optical Breadboard Selection Guides

The selection guides below list every size offered for our honeycomb, solid aluminum, and acrylic breadboards. Simply locate the specific width and length needed and then select the type of breadboard. Expand each table by clicking the More [+] button within the header.

Thorlabs also offers several unique breadboard solutions. For applications requiring temperature control, we offer anodized aluminum water cooled breadboards in several sizes, in addition to a temperature-controlled mini-series breadboard for small-scale operations. Our anodized aluminum large-area translation stages and rotating breadboards offer hand-operated positioning control, while our manual and motorized translating mounting platforms are ideal for use in microscopy applications.

| Imperial Optical Breadboard Size Options | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Honeycomb | Stainless Steel | Solid Aluminuma | Acrylic, Transparent | ||||||

| Nexus (60 mm Thick)b |

Nexus (110 mm Thick)b |

Intrinsically Damped (58 mm Thick) |

Aluminum (25 mm Thick) |

Aluminum (55 mm Thick) |

Standard | Double Density | High Density | ||||

| Metric Optical Breadboard Size Options | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Honeycomb | Stainless Steel | Solid Aluminuma | ||||||

| Nexus (60 mm Thick)b |

Nexus (110 mm Thick)b |

Intrinsically Damped (58 mm Thick) |

Aluminum (25 mm Thick) |

Aluminum (55 mm Thick) |

Standard | Double Density | High Density | |||

| 50 mm | 75 mm | - | - | - | - | - | - | - | - | MSB5075/M |

| 75 mm | 100 mm | - | - | - | - | - | - | - | - | MSB7510/M |

| 75 mm | 150 mm | - | - | - | - | - | - | - | - | MSB7515/M |

| 100 mm | 100 mm | - | - | - | - | - | MB10S/M | - | - | - |

| 100 mm | 150 mm | - | - | - | - | - | MB1015S/M | MB1015/M MB1015U/M |

M45B1015/Mc | MSB1015/M |

| 100 mm | 300 mm | - | - | - | - | - | - | MB1030/M | - | - |

| 100 mm | 600 mm | - | - | - | - | - | - | - | MB1060/M | - |

| 100 mm | 900 mm | - | - | - | - | - | - | - | MB1090/M | - |

| Ø149 mm | - | - | - | - | - | - | - | MBR150U/M | - | |

| Ø150 mm | - | - | - | - | - | - | - | MBR150/M | - | |

| 150 mm | 150 mm | - | - | - | - | - | MB15S/M | MB1515/M MB1515U/M |

M45B1515/Mc | MSB15/M |

| 150 mm | 300 mm | - | - | - | - | - | - | MB1530F/M | MB1530/M M45B1530/Mc |

- |

| 150 mm | 450 mm | - | - | - | - | - | - | MB1545/M | - | - |

| 150 mm | 600 mm | - | - | - | - | - | - | MB1560/M | - | - |

| 150 mm | 900 mm | - | - | - | - | - | - | MB1590/M | - | - |

| 150 mm | 1200 mm | - | - | - | - | - | - | MB15120/M | - | - |

| 180 mm | 230 mm | - | - | - | - | - | - | - | - | MSB1823/M MSBU1823/M |

| 200 mm | 200 mm | - | - | - | - | - | - | MB2020/M MB2020U/M |

- | - |

| 200 mm | 250 mm | - | - | - | - | - | - | MB2025/M | - | - |

| 200 mm | 600 mm | - | - | - | - | - | - | - | MB2060/M | - |

| 200 mm | 900 mm | - | - | - | - | - | - | - | MB2090/M | - |

| 250 mm | 300 mm | - | - | - | - | - | - | MB2530/M MB2530U/M |

- | - |

| Ø300 mm | - | - | - | - | - | - | - | MBR300/M MBR300U/M |

- | |

| 300 mm | 300 mm | B3030Ad B3030Ld |

- | - | PBG3030Ae | - | - | MB3030/M MB3030U/M |

MB3030D/M | MS12B/M MSB30/M |

| 300 mm | 450 mm | B3045Ad B3045Ld |

- | B3045AX | PBG3045Ae | - | - | MB3045/M MB3045A/Mf MB3045U/M |

- | MSB3045/M |

| 300 mm | 600 mm | B3060Ad B3060L |

- | B3060AXd | PBG3060A | PBG52502d | - | MB3060/M MB3060U/M |

- | - |

| 300 mm | 900 mm | B3090Ad B3090Ld |

- | - | PBG3090Ae | PBG52503d | - | MB3090/M | - | - |

| 300 mm | 1200 mm | - | - | - | - | - | - | MB30120/M | - | - |

| 350 mm | 1150 mm | - | - | - | - | - | - | MB35115/M | - | - |

| 350 mm | 1425 mm | - | - | - | - | - | - | MB35142/M | - | - |

| 450 mm | 450 mm | B4545Ad B4545Ld |

- | - | PBG4545A | - | - | MB4545/M | - | - |

| 450 mm | 600 mm | B4560Ad B4560Ld |

- | B4560AXd | PBG4560Ae | PBG52522d | - | MB4560/M MB4560A/Mf MB4560U/M |

- | - |

| 450 mm | 750 mm | - | - | - | - | - | - | MB4575/M | - | - |

| 450 mm | 900 mm | - | - | - | - | - | - | MB4590/M | - | - |

| 600 mm | 600 mm | B6060Ad B6060L |

- | B6060AXd | PBG6060Ae | PBG52505d | - | MB6060/M | - | |

| 600 mm | 900 mm | B6090A B6090L B6090ANd B6090Z |

B6090Bd B6090Nd |

B6090AX | PBG6090Ae | PBG52506d | - | MB6090/M | - | - |

| 600 mm | 1200 mm | B60120A B60120L |

B60120Bd B60120Nd |

B60120AX | PBG60120Ae | - | - | MB60120/M | - | - |

| 600 mm | 1500 mm | - | B60150Bd B60150Nd |

- | - | PBG52508d | - | - | - | - |

| 750 mm | 750 mm | B7575A B7575L |

- | - | - | - | - | MB7575/M | - | - |

| 750 mm | 900 mm | B7590A B7590L B7590ANd B7590Z |

B7590Bd B7590Nd |

B7590AX | PBG7590Ae | PBG52510d | - | - | - | - |

| 750 mm | 1200 mm | B75120A B75120L B75120ANd B75120Z |

B75120B B75120Nd |

B75120AX | PBG75120Ae | PBG52511 | - | - | - | - |

| 750 mm | 1500 mm | - | B75150B B75150N |

B75150AX | - | - | - | - | - | - |

| 900 mm | 900 mm | B9090A B9090L |

B9090Bd B9090Nd |

- | - | - | - | - | - | - |

| 900 mm | 1200 mm | B90120A B90120L B90120AN B90120Z |

B90120B B90120N |

B90120AX | PBG90120Ae | PBG52513 | - | - | - | - |

| 900 mm | 1500 mm | - | B90150B B90150N |

B90150AX | - | PBG52514 | - | - | - | - |

| 900 mm | 1800 mm | - | B90180B B90180N |

B90180AX | - | - | - | - | - | - |

| 1200 mm | 1500 mm | - | B120150Bd B120150Nd |

- | - | - | - | - | - | - |

| 1200 mm | 1800 mm | - | B120180B B120180Nd |

- | - | - | - | - | - | - |

| 1250 mm | 1800 mm | - | - | - | - | PBG52521 | - | - | - | - |

Products Home

Products Home

Aluminum Breadboards, 25 mm Thick

Aluminum Breadboards, 25 mm Thick